Patents

Literature

50results about How to "Raise the sensory value" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

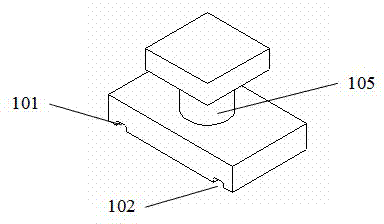

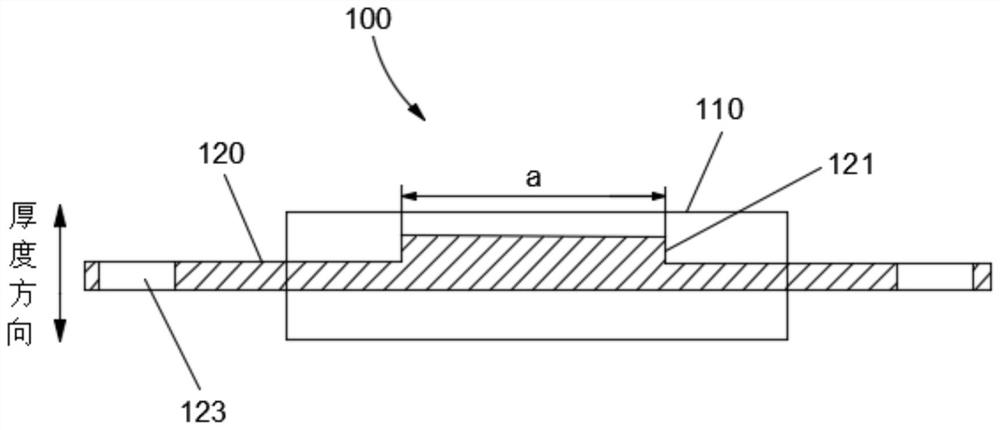

Power inductance element formed by molding and manufacturing method thereof

ActiveCN102856037AGood electrical performance consistencyNot easy to shiftTransformers/inductances coils/windings/connectionsTransformers/inductances magnetic coresMiniaturizationEngineering

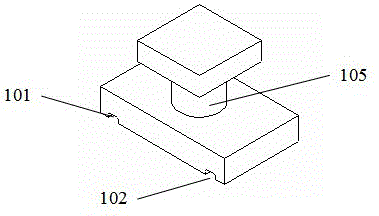

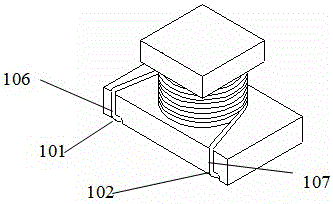

The invention discloses a power inductance element formed by molding. The power inductance element comprises a prefabricated magnetic core, a coil and a magnetic plastic package layer, wherein the coil is placed on the prefabricated magnetic core; the magnetic plastic package layer is formed by molding and is used for covering the magnetic core and the coil; and an electrode connected with the coil is exposed. The invention also discloses a method for manufacturing the power inductance element formed by molding. The method comprises the following steps of: a, prefabricating the magnetic core and placing the coil on the prefabricated core; and b, covering the magnetic plastic package layer on the magnetic core and the coil by virtue of molding and exposing the electrode connected with the coil. The power inductance product has the advantages of thinning, miniaturization and high reliability.

Owner:SUNLORD (SHANGHAI) ELECTRONICS CO

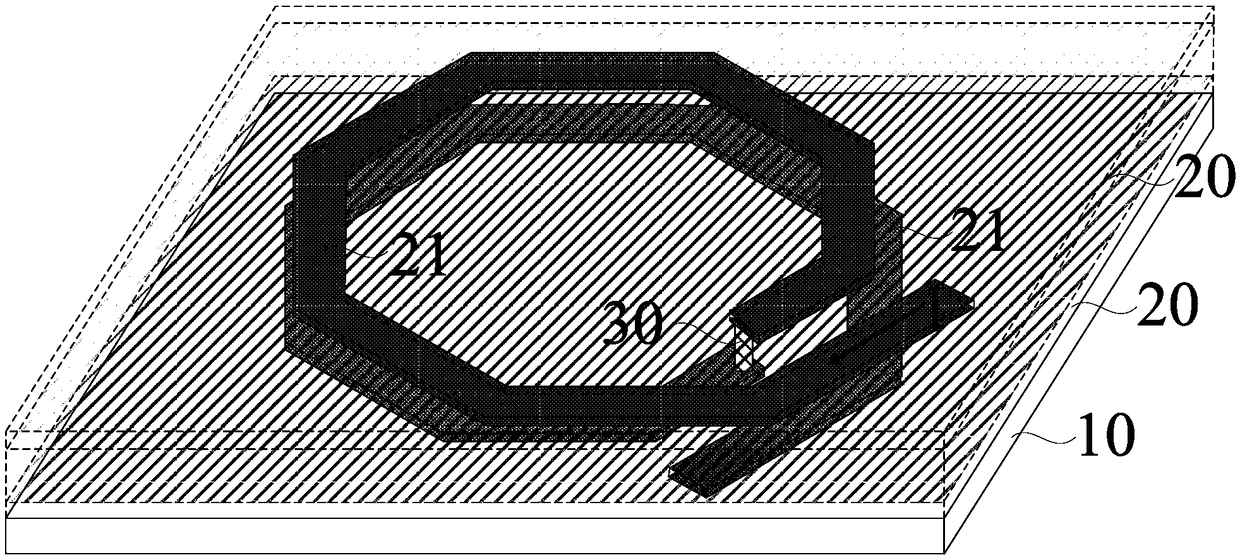

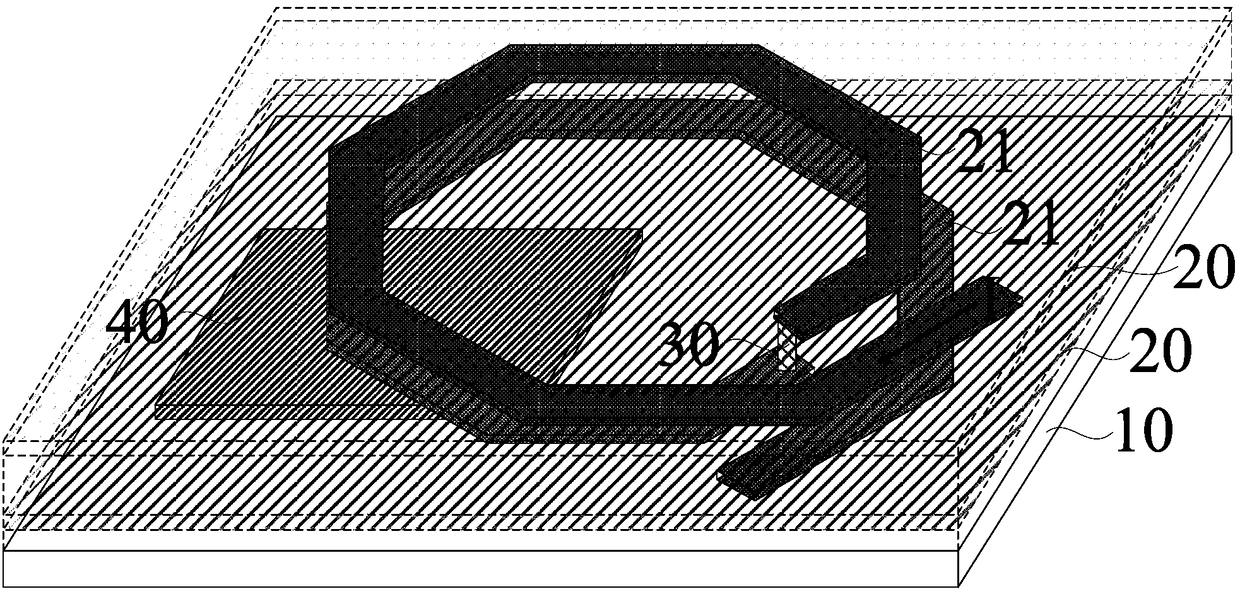

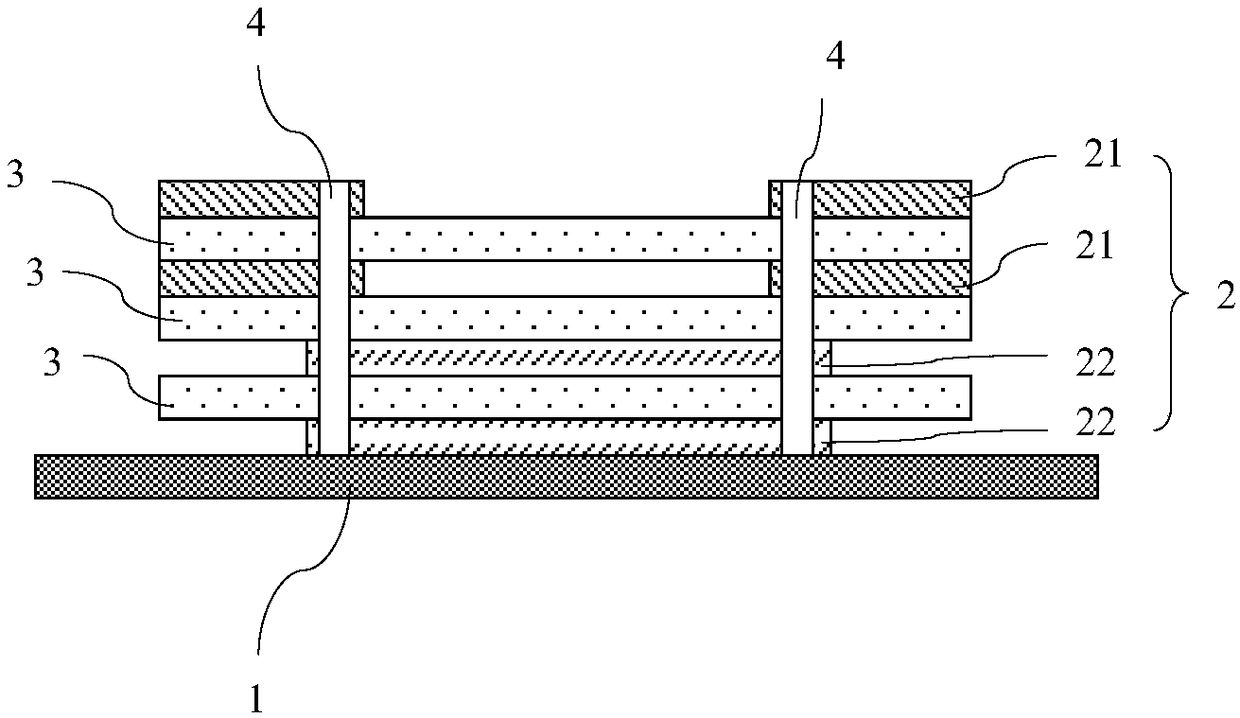

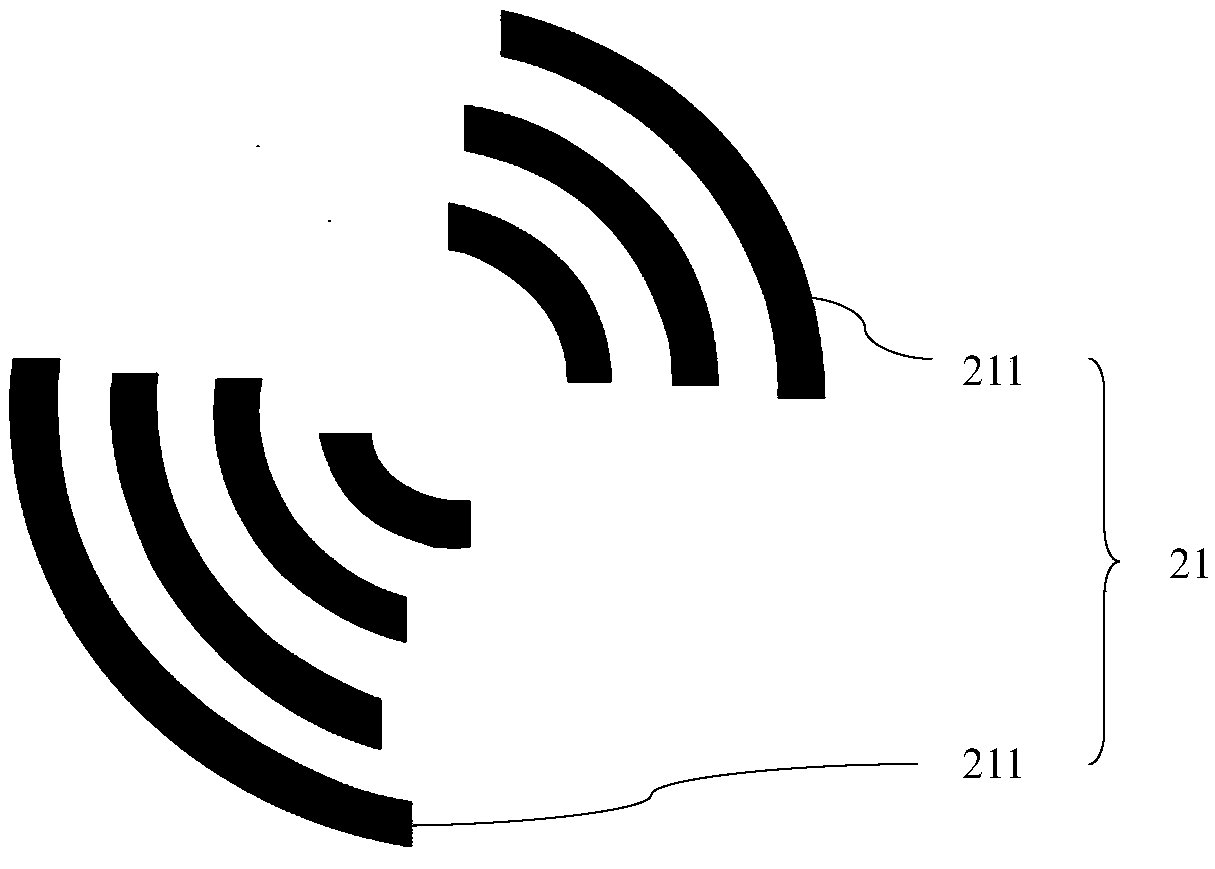

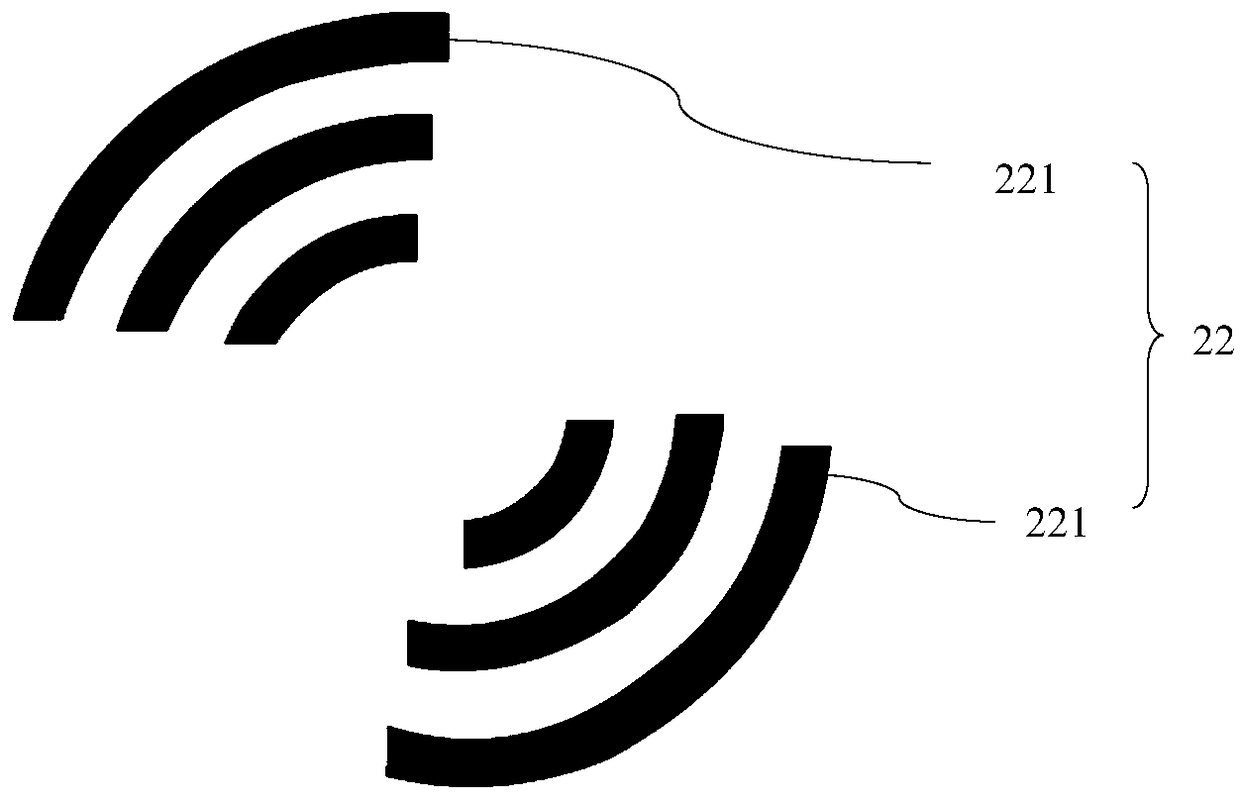

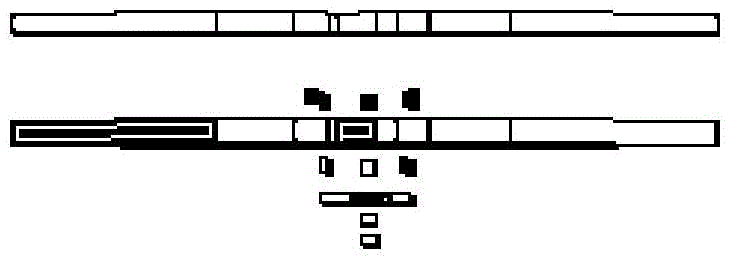

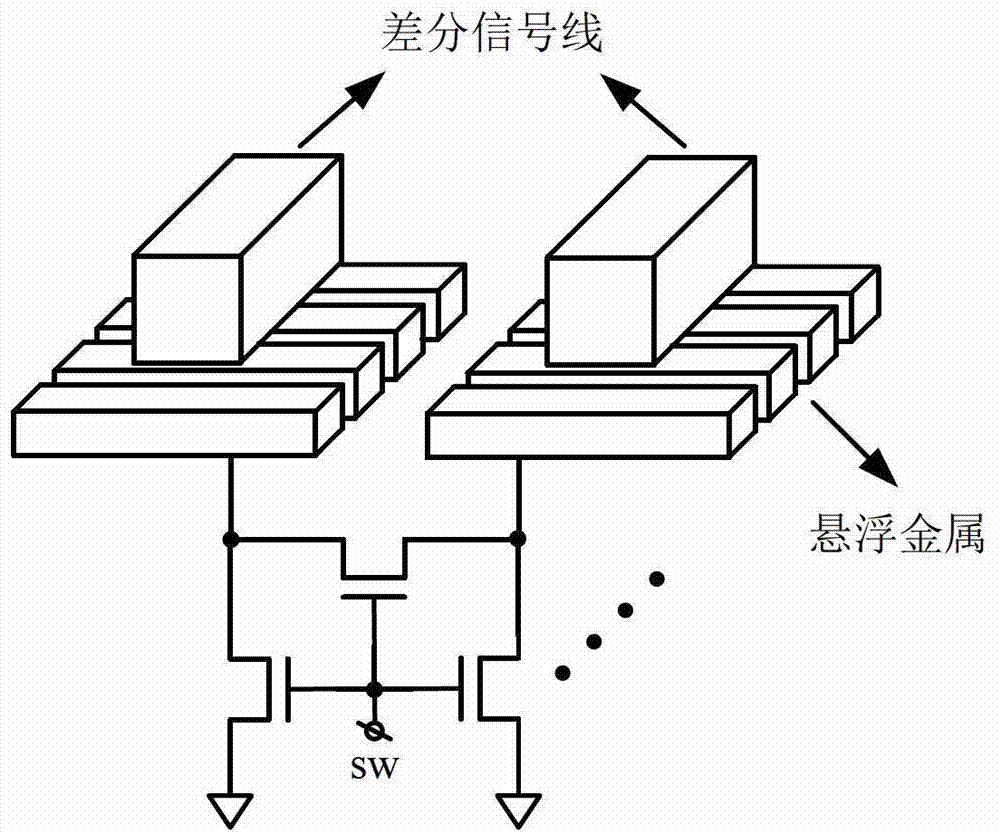

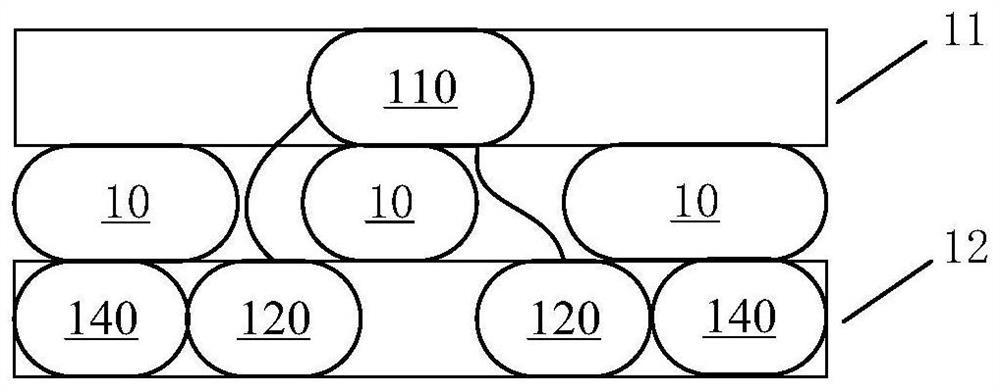

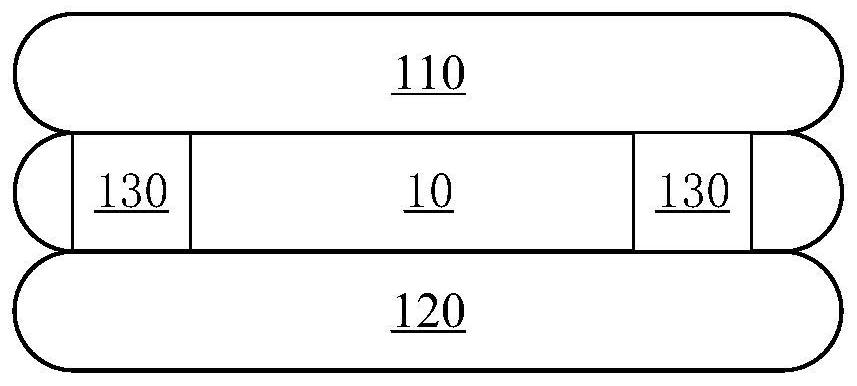

Inductor stacking structure

PendingCN108346642ARaise the sensory valueImprove qualitySemiconductor/solid-state device detailsTransformers/inductances coils/windings/connectionsState of artParasitic capacitance

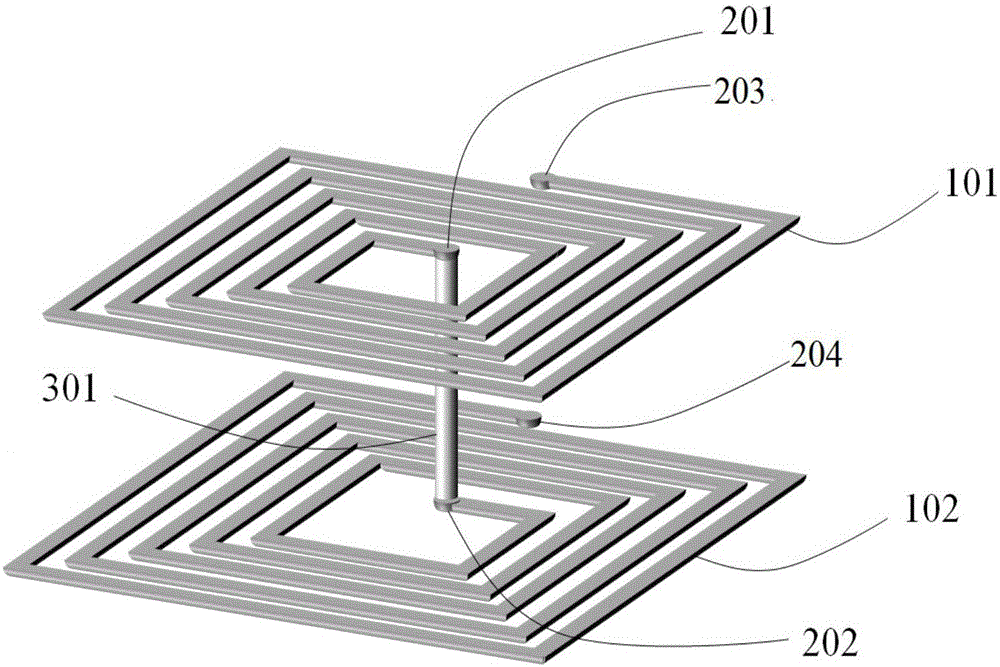

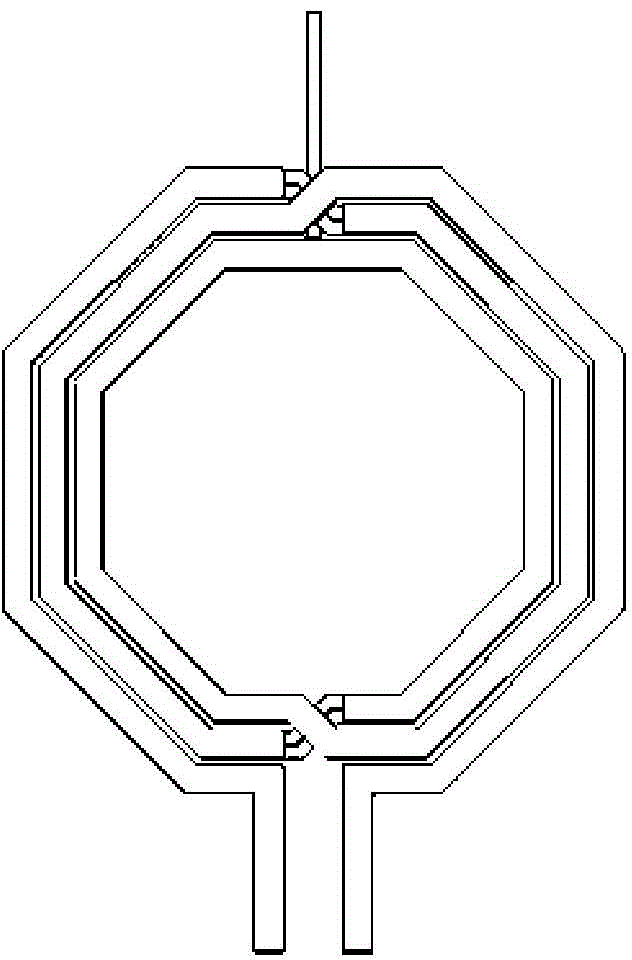

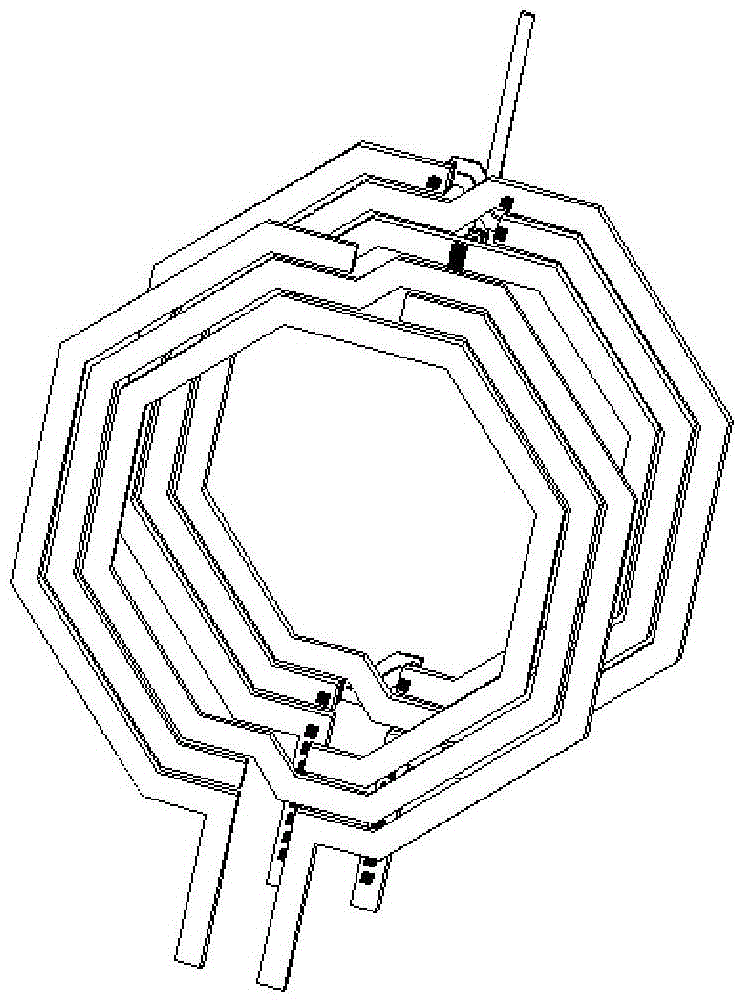

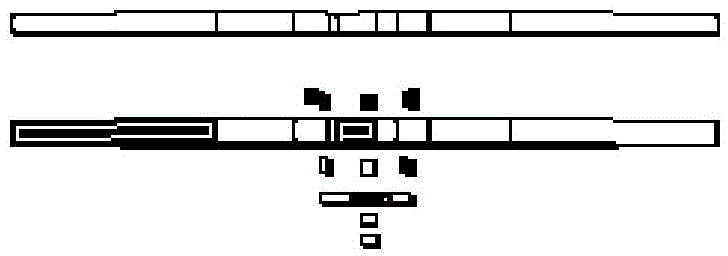

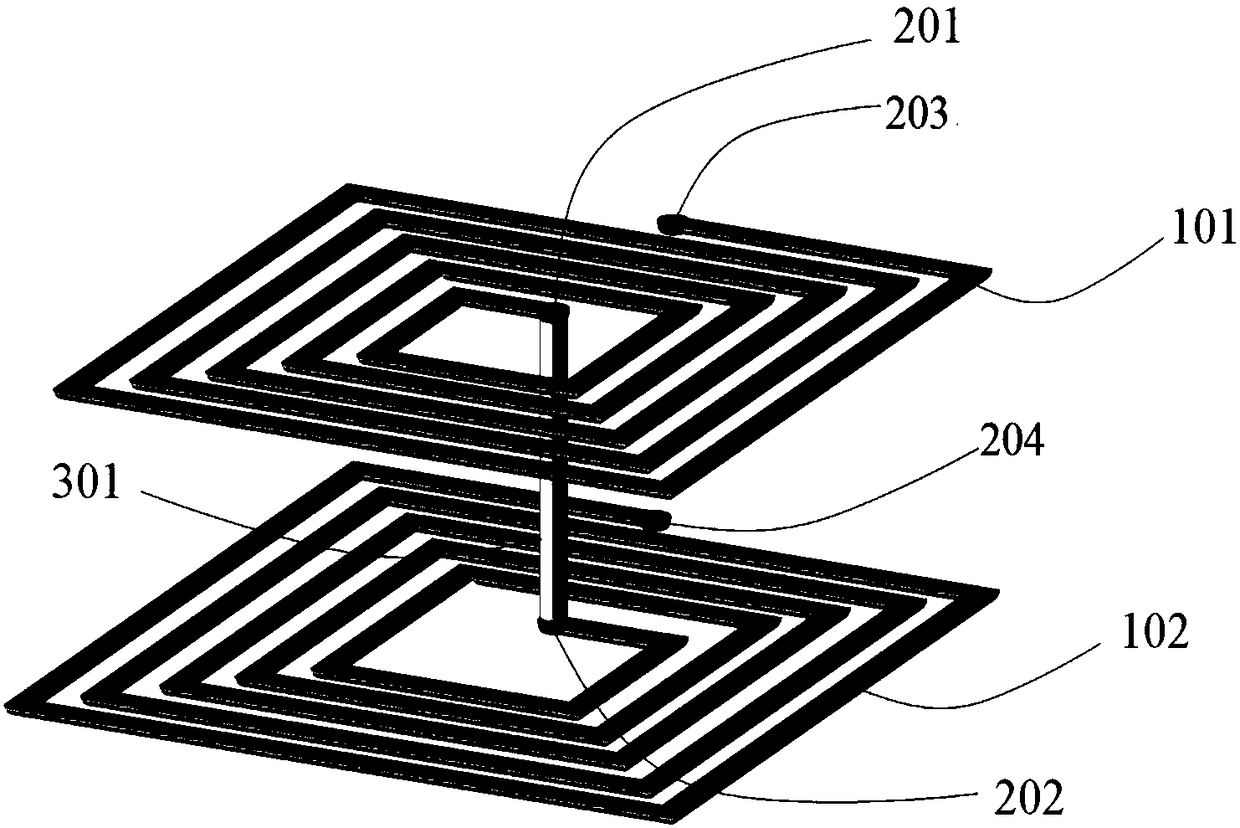

The present invention discloses an inductor stacking structure. The inductor stacking structure comprises: a substrate; at least two metal layers stacked at one side of the substrate in order, each metal layer at least comprising one first planar inductor; through holes located between any two adjacent metal layers, wherein the first planar inductors in different metal layers are electrically connected through the through holes, and the thickness of the through holes is larger than the thickness of the metal layers. The multiple metal layers with the first planar inductors are arranged to increase the inductance values of the inductors in the inductor stacking structure, the through holes with the thickness larger than the thickness of the metal layers are employed to connect the first planar inductors in the metal layers to reduce the interference among the first planar inductors. Compared to the prior art, in a condition that the mutual inductance among the fist planar inductors in the different metal layers is not greatly reduced, stray capacitance between the different metal layers can be greatly reduced to allow the inductor to keep a high inductance value and a quality factorwhen the inductor has a small area and reduce the area of an integration circuit.

Owner:ANHUI YUNTA ELECTRONICS TECH CO LTD

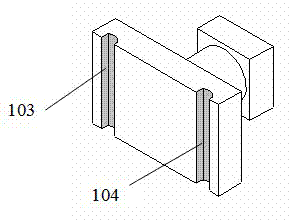

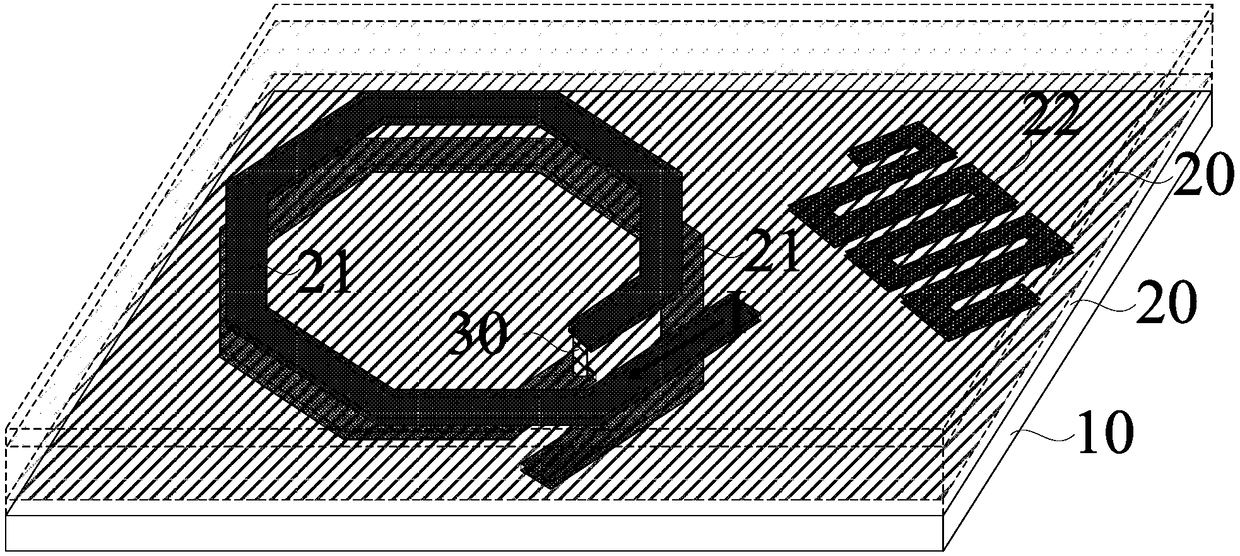

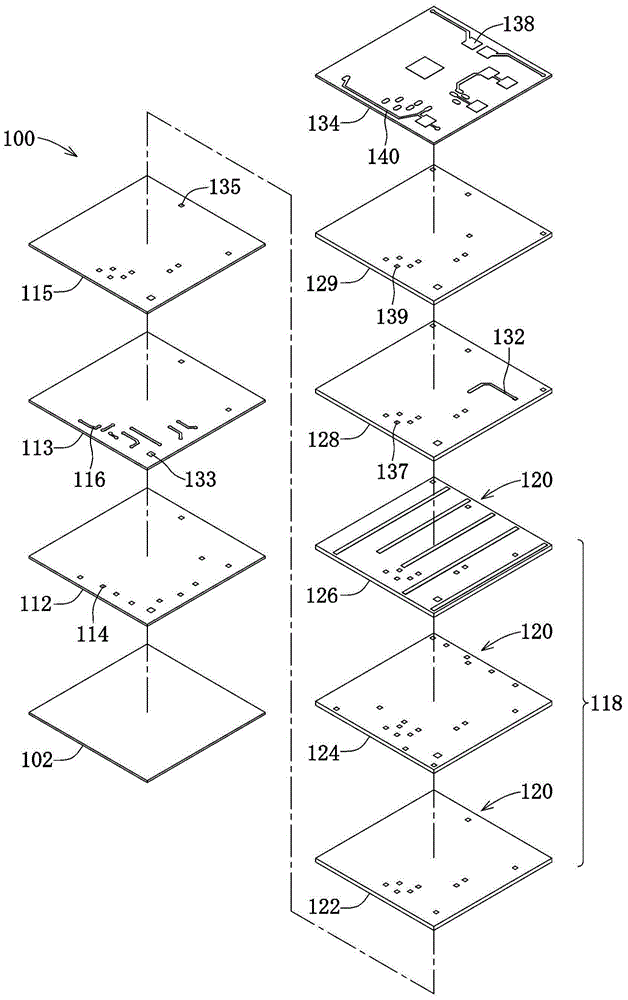

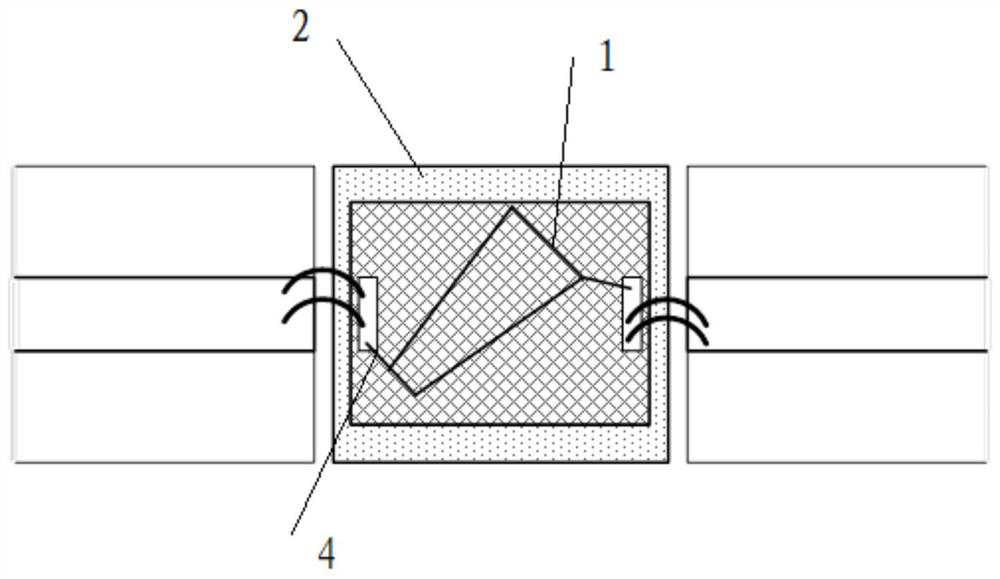

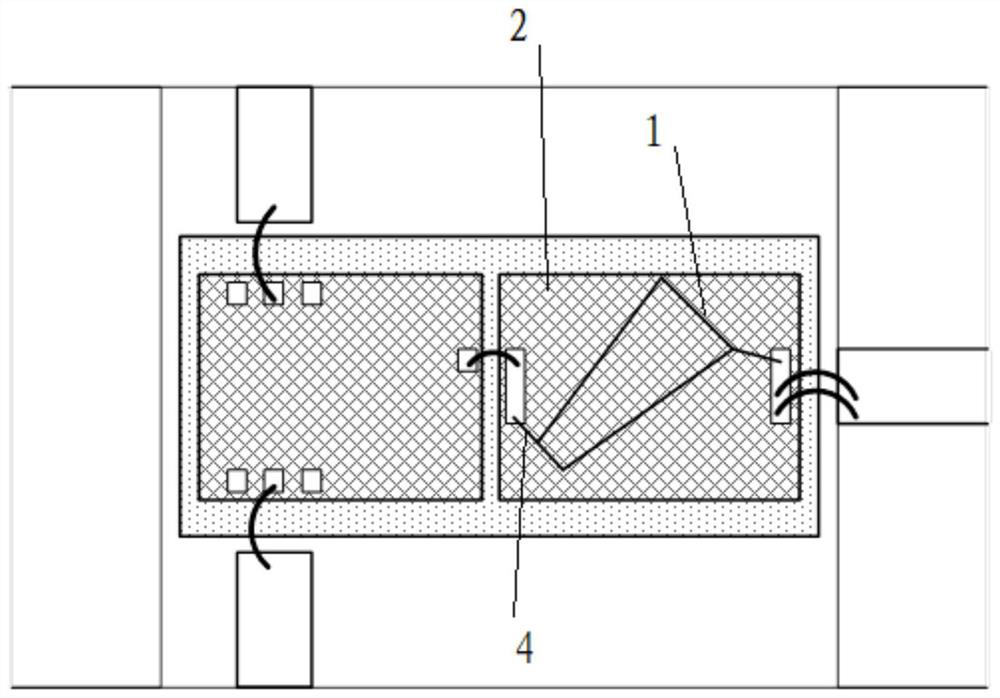

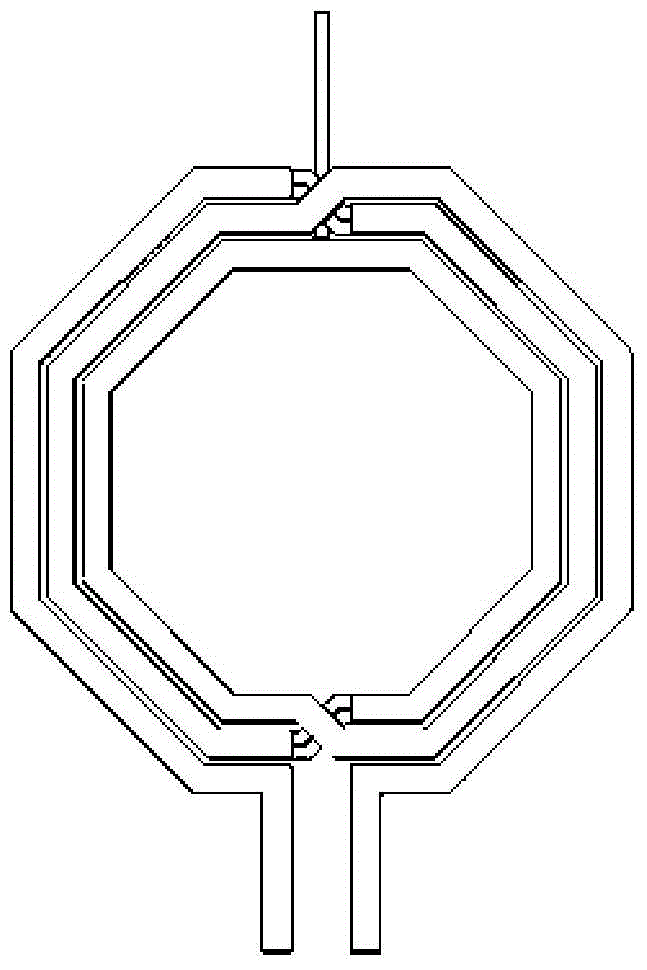

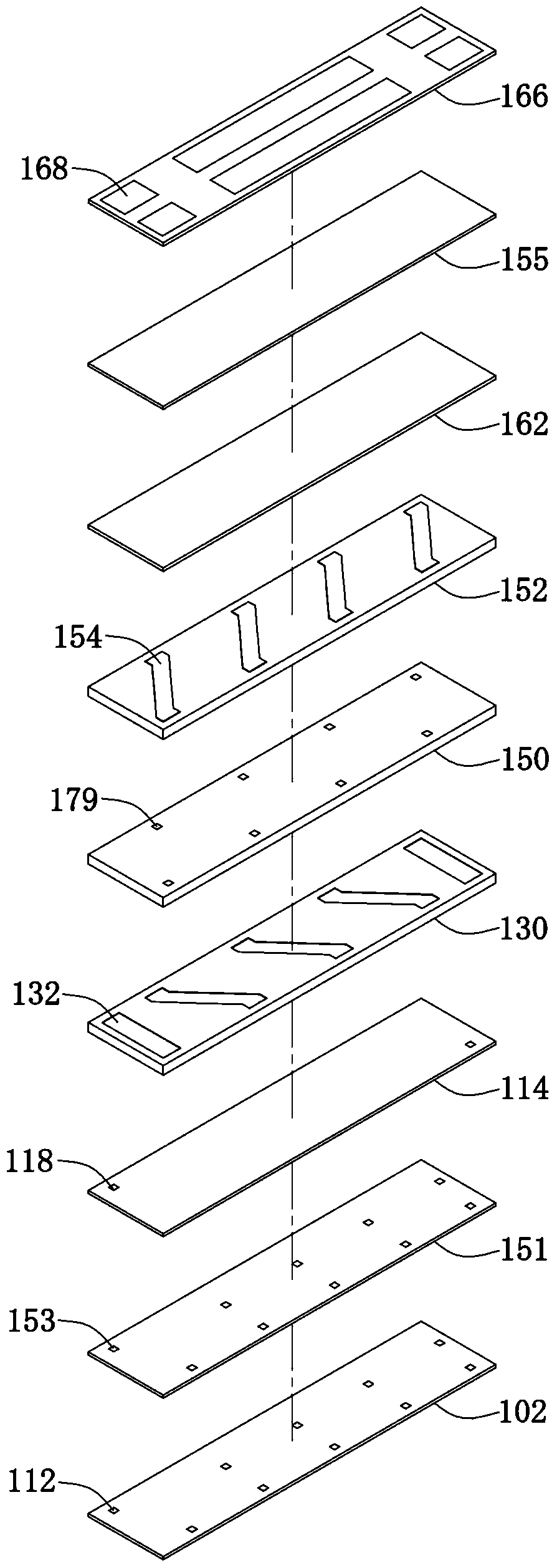

Inductor structure used for printed circuit board embedding technology and manufacturing method thereof

ActiveCN106332447AMeet the requirements of low-cost manufacturingRaise the sensory valuePrinted inductor incorporationInductorCopper coil

The invention provides an inductor structure used for a printed circuit board embedding technology, and belongs to the technical field of printed circuit integrated elements. According to the structure and the method, the inductance and the stability of the inductor in a usage process are increased through improvement of structures of magnetic cores and the surrounding mode of coils; according to the inductor structure, the occupied area of the copper coils on a PCB substrate can be reduced, the dimension micromation degree of inductor elements is improved, and the prepared inductor is advantaged by small size and high performance; and the inductor structure used for the printed circuit board embedding inductance technology is mainly formed by employing processes such as the pattern transfer technology, interlayer hole penetration, windowing processing, electroplating and electroless plating, and hot pressing layering etc., the manufacturing method is simple, the controllability is high, the inductor structure is compatible with the conventional process of the printed circuit board technology, and the integration degree of the elements of the printed circuit can be improved.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

Molding power inductance element and manufacturing method thereof

ActiveCN111508685AReduce leakage fluxHigh space marginTransformers/inductances coils/windings/connectionsTransformers/inductances magnetic coresInductorMagnetic core

The invention provides a plastic molding power inductance element and a manufacturing method thereof. The plastic molding power inductance element comprises a conductor, a magnetic core and a magneticplastic packaging layer, wherein the conductor comprises a base part subjected to insulation treatment, a side edge enclosing part subjected to insulation treatment and an electrode part which are integrally formed, the base part and the side edge enclosing part are assembled together with the magnetic core in a gapless fit manner, and the magnetic plastic packaging layer wraps the conductor andthe magnetic core in a gapless manner. According to the invention, the method is used for manufacturing the plastic molding power inductance element; the plastic packaging layer completely wraps the prefabricated magnetic core and the part, except the electrodes, of the conductor and is of an integrally-formed structure, so that leakage flux is small; and when the equivalent magnetic conductivityreaches more than 60, the equivalent saturation magnetic flux density can reach more than 0.55 T, the space utilization rate is high, and the design of a miniaturized inductor is facilitated.

Owner:SHENZHEN SUNLORD AUTOMOTIVE ELECTRONICS CO LTD

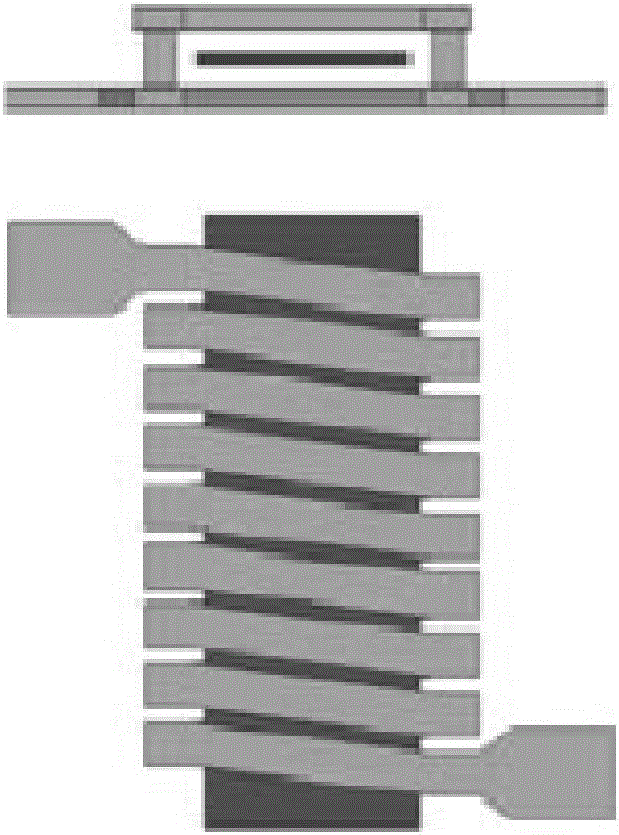

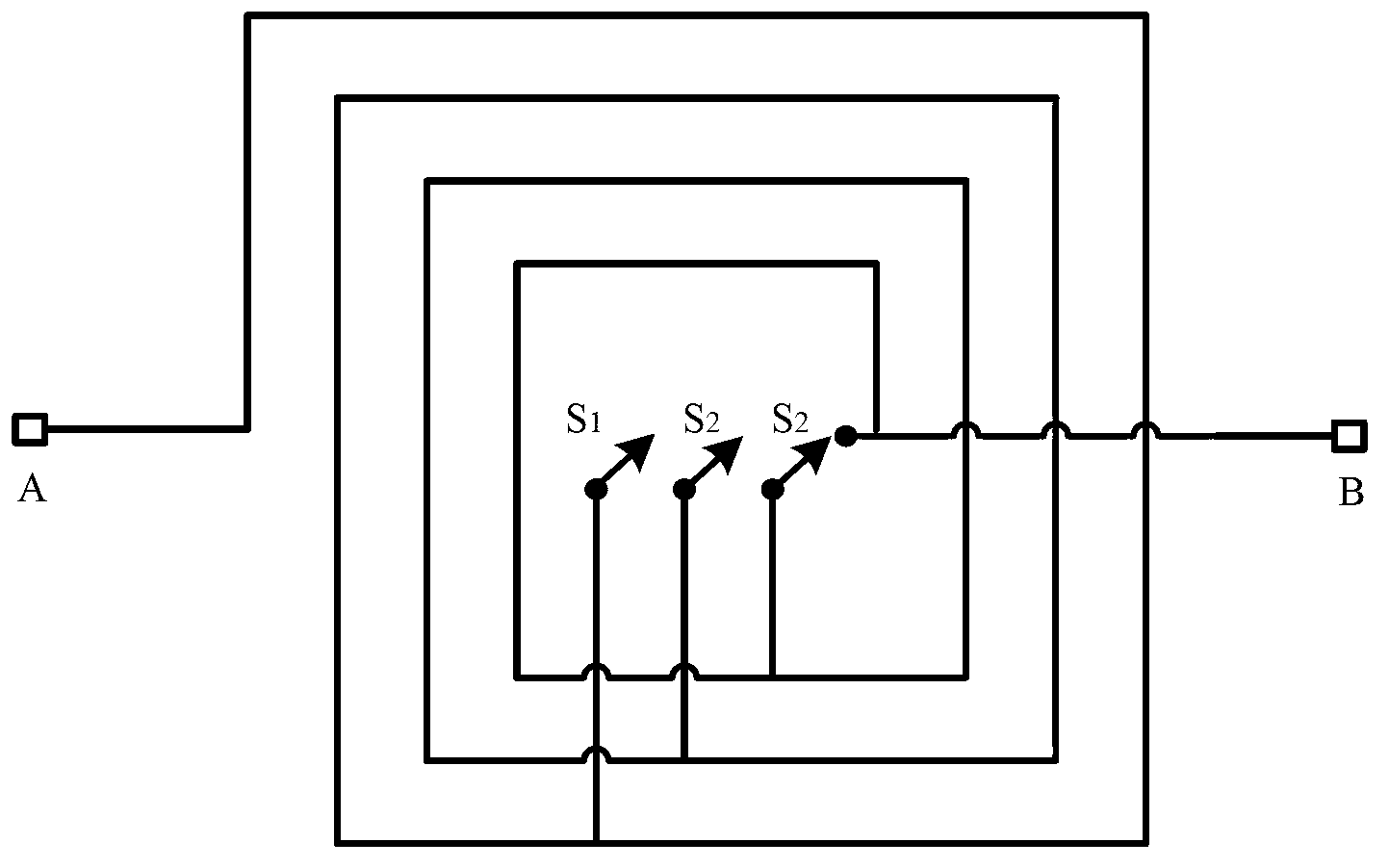

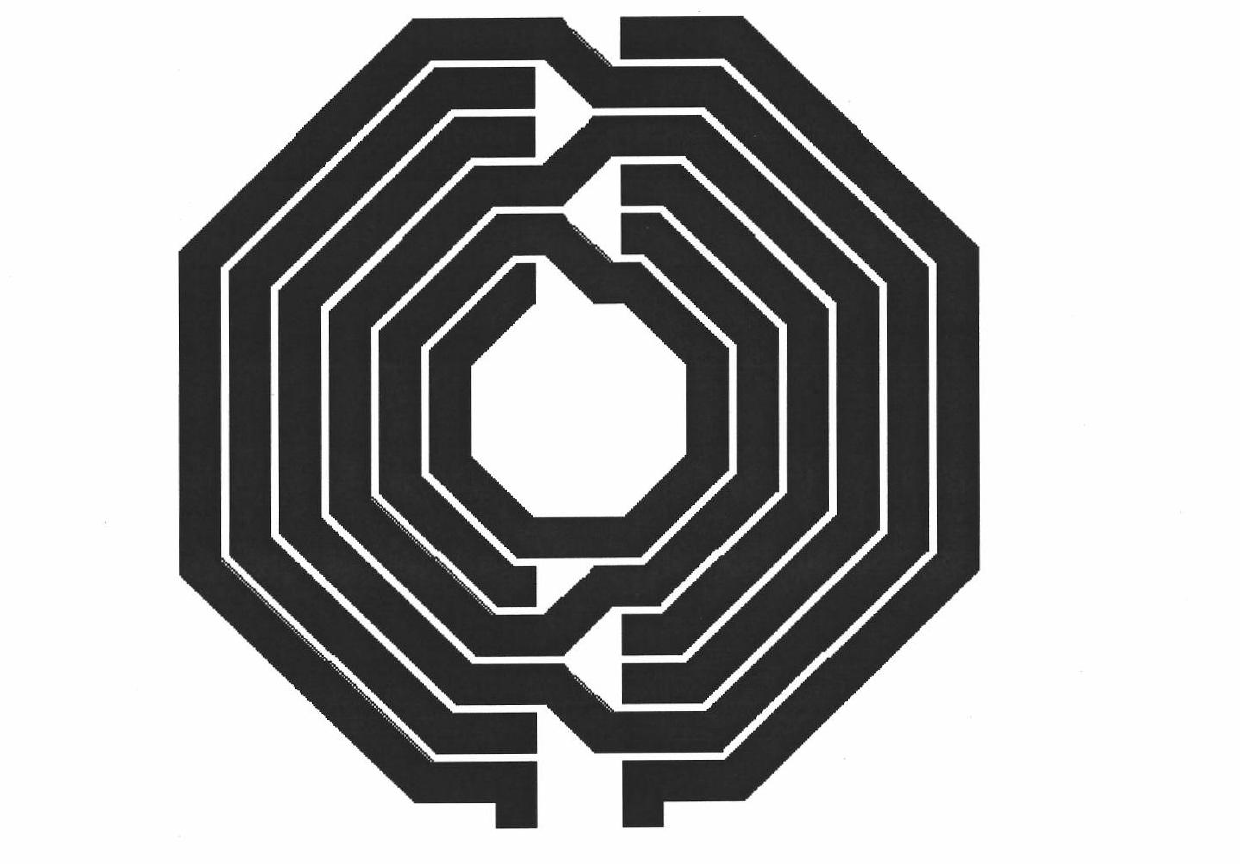

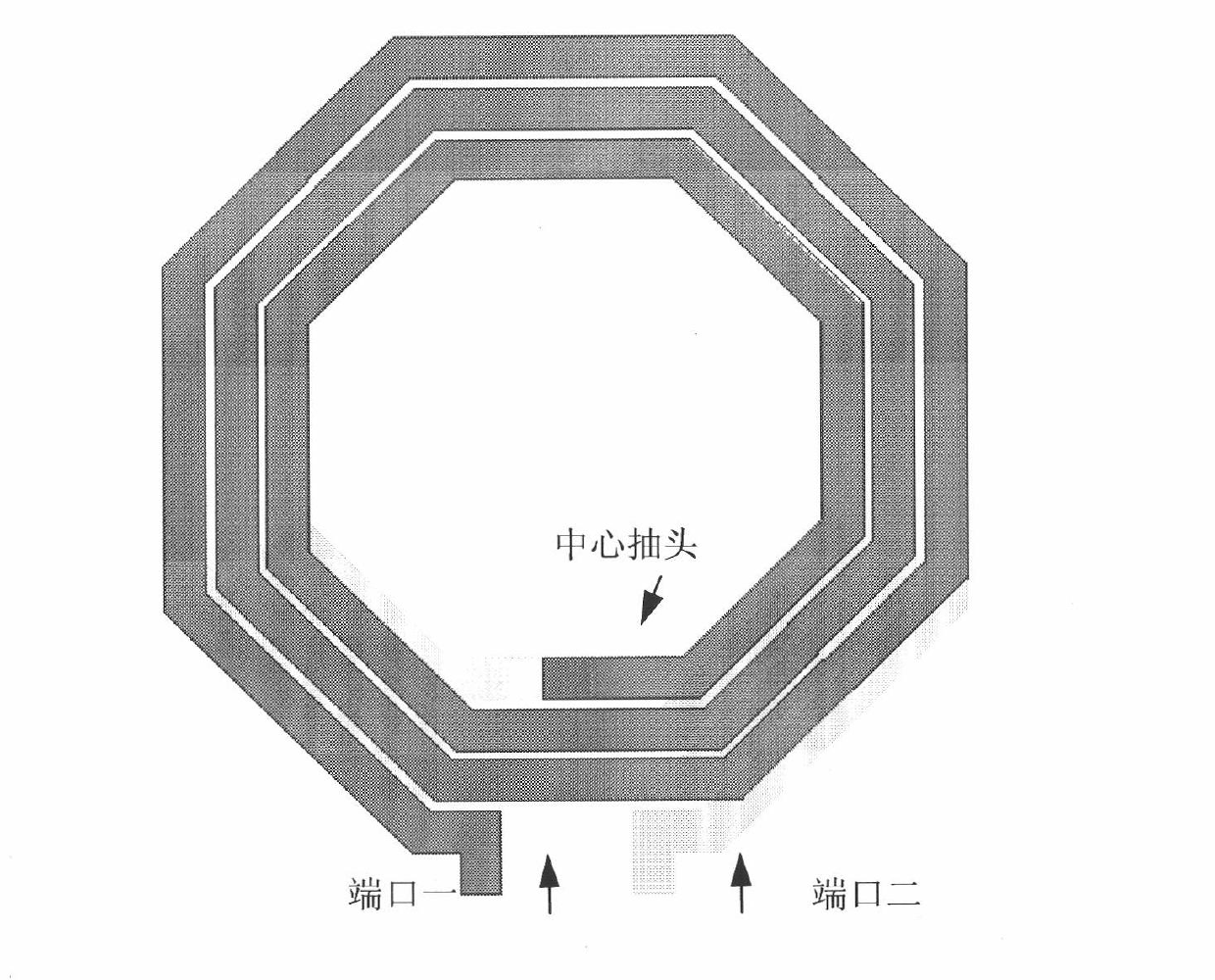

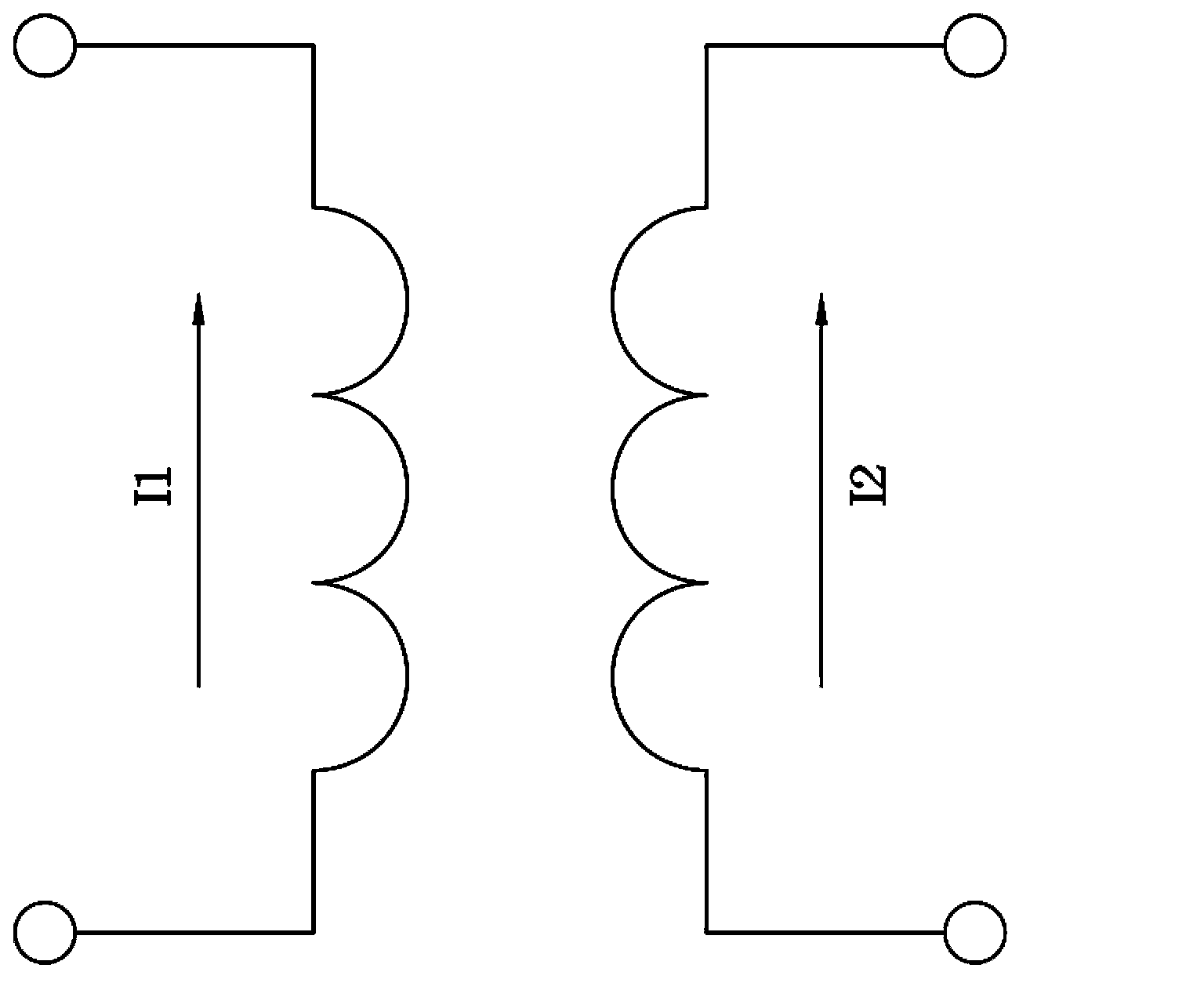

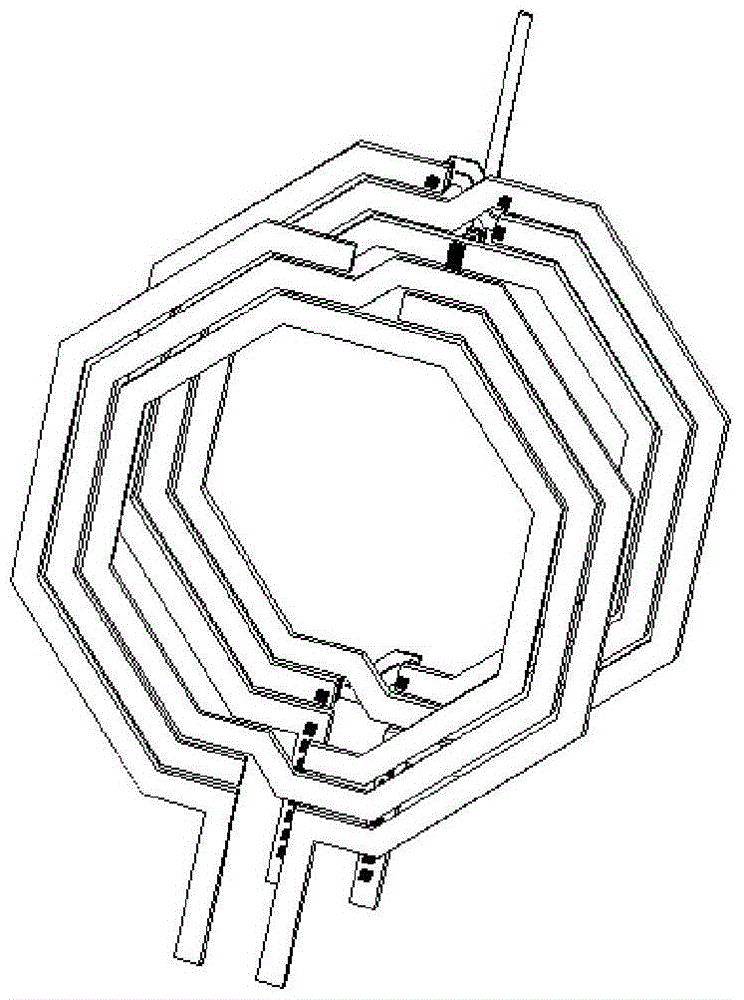

Differential inductor

ActiveCN104810349AIncreasing the thicknessReduce connection resistanceSemiconductor/solid-state device detailsTransformers/inductances coils/windings/connectionsCross connectionInductor

The invention provides a differential inductor which at least comprises a first port, a second port and a bottom coil. Inner and outer metal coils of the bottom coil are in cross connection through a plurality of first diagonal connectors. A top metal coil is formed right above the outmost metal coil of the bottom coil. The top metal coil is connected in parallel with the bottom coil through the first port, the second port and a plurality of contacts. Only the outmost metal layers of the top metal coil and the bottom coil are stacked, and the top metal coil and the bottom coil share all the metal coils of the bottom coil except the outmost metal coil. According to the inductor of the invention, the top metal coil and the bottom coil are connected in parallel, and only the outmost metal layers are stacked, so that the coupling capacitance is reduced; the thickness of the joint is increased, the energizing capability of the coils is improved, and the loss is reduced; and the Q value of the inductor can be integrally improved by more than 15% through joint action of the top metal coil and the bottom coil.

Owner:SEMICON MFG INT (SHANGHAI) CORP

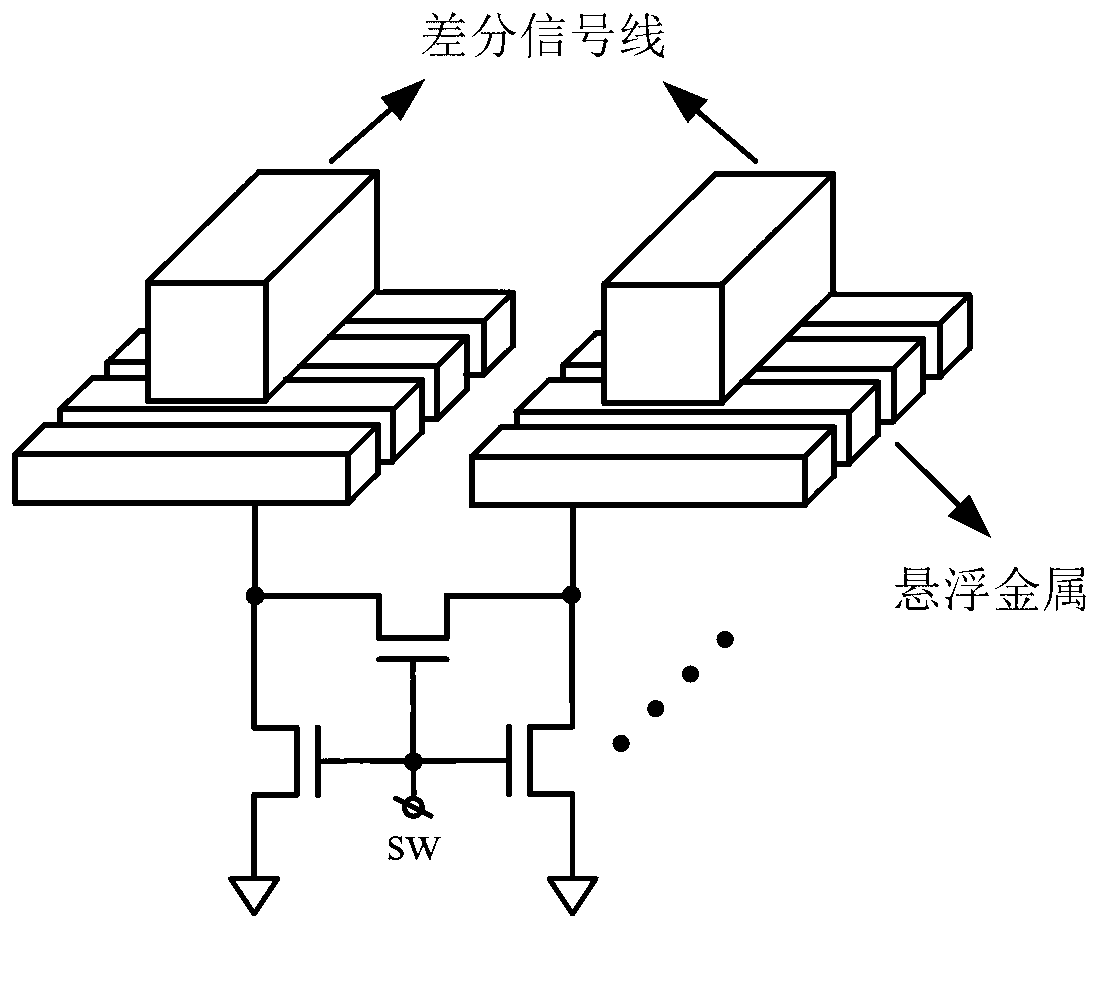

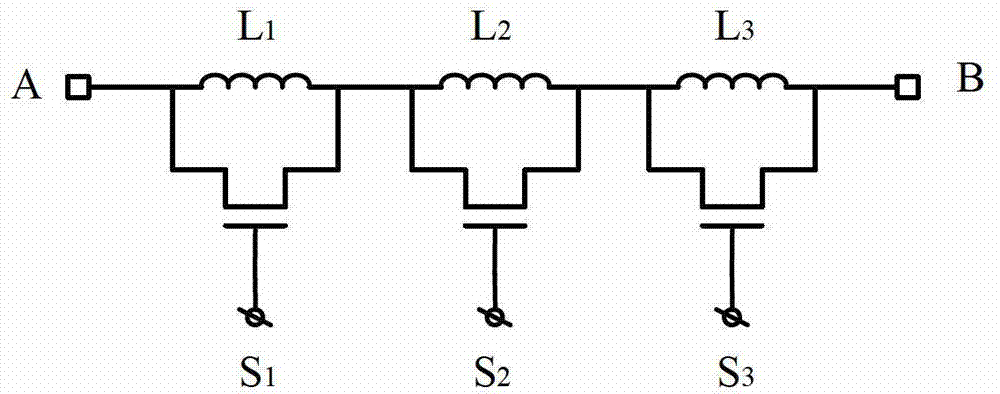

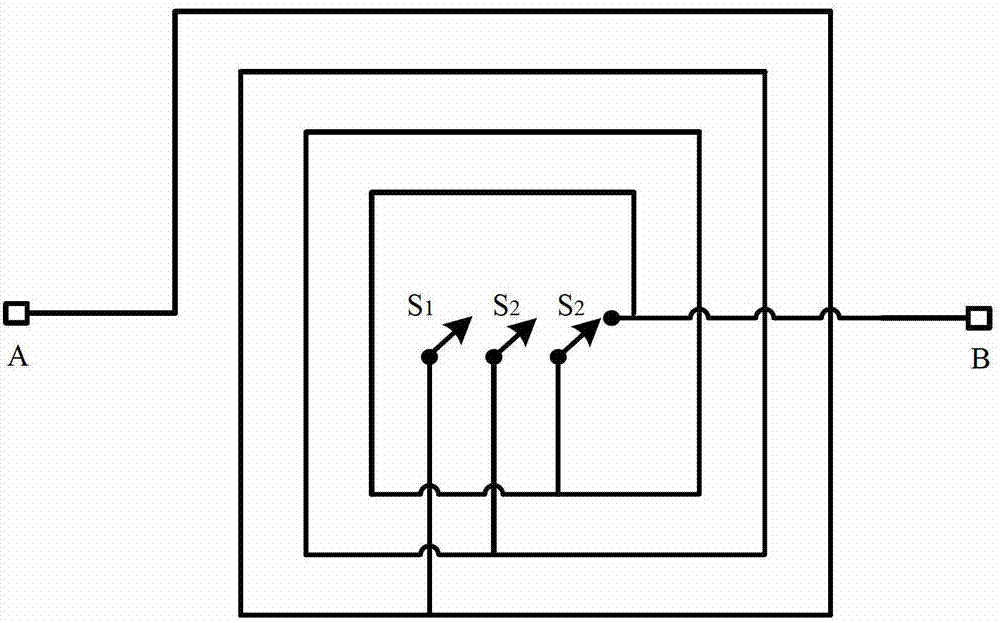

Adjustable on-chip inductor with superhigh Q value

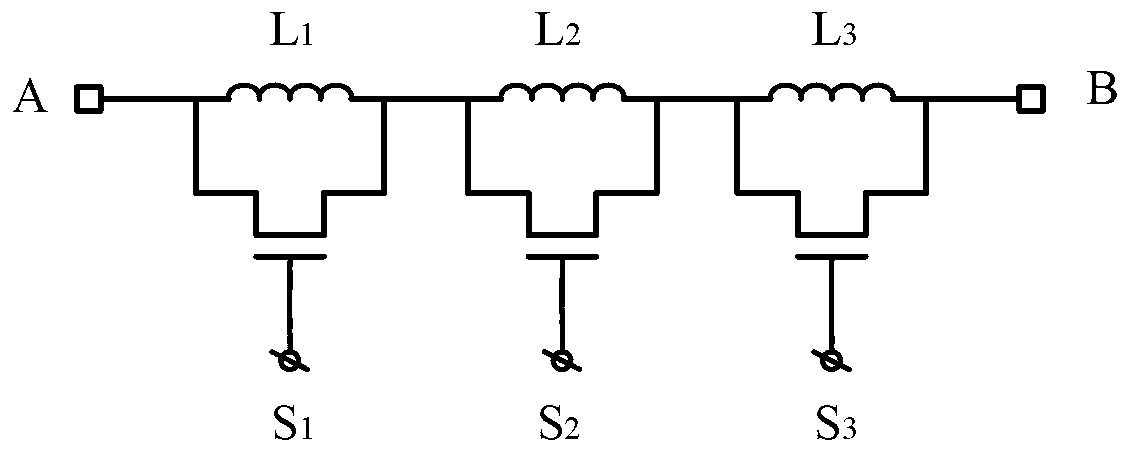

ActiveCN103001566AImprove reconfigurabilityImprove noiseTransformersConversion without intermediate conversion to dcCapacitanceControl signal

An adjustable on-chip inductor with a superhigh Q value comprises an inductor unit, a capacitance regulating and controlling unit and a negative resistance regulating and controlling unit. The inductor unit is provided with a primary inductor and a secondary inductor with electromagnetically coupled, and two ends of the primary inductor are connected with radio frequency output. The capacitance regulating and controlling unit is provided with two serially connected variable capacitors C1 and C2, the serial connection ends of the variable capacitors C1 and C2 are connected with an external control signal VC1, and the other ends of the variable capacitors C1 and C2 are respectively connected with an in-phase end and an inverse-phase end of the secondary inductor. The negative resistance regulating and controlling unit is provided with five transistors, a grid electrode of the transistor M1 is connected with an externally input control signal VC2, a source electrode of the transistor M1 is earthed, a drain electrode of the transistor M1 is connected together with source electrodes of the transistors M2 and M3, a grid electrode of the transistor M2 is connected together with drain electrodes of the transistors M3 and M5 and a grid electrode of the transistor M4 and the inverse-phase end of the secondary inductor, a grid electrode of the transistor M3 is connected together with drain electrodes of the transistors M2 and M4 and a grid electrode of the transistor M5 and the in-phase end of the secondary inductor, and source electrodes of the transistors M4 and M5 are connected with a power source VDD (voltage drain drain).

Owner:NANJING QINHENG MICROELECTRONICS CO LTD

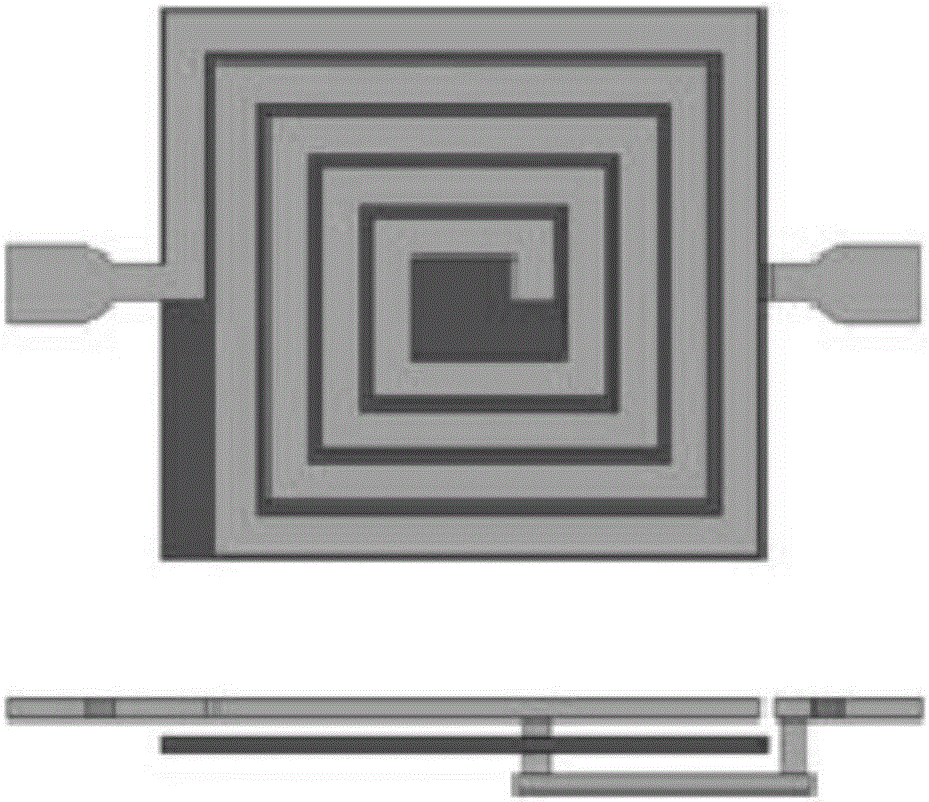

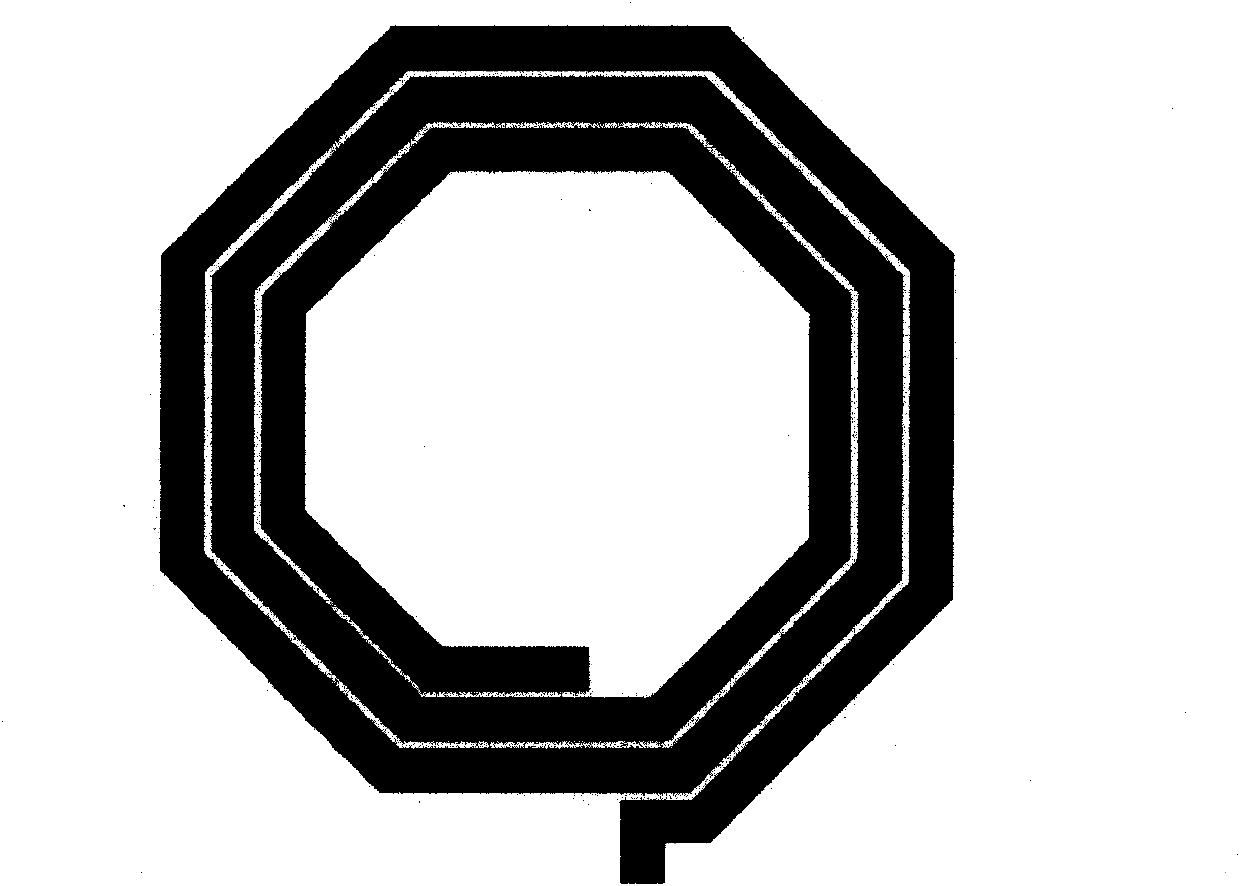

Laminated differential inductor with top layer metal and second layer metal of equal thickness

InactiveCN102087912ARaise the sensory valueImprove Q valueSemiconductor/solid-state device detailsTransformers/inductances coils/windings/connectionsInductorInductance

The invention discloses a laminated differential inductor with a top layer metal and a second layer metal of equal thickness. The laminated differential inductor has a multilayer structure and comprises an upper layer metal coil and a lower layer metal coil, wherein the upper layer metal coil and the lower layer metal coil have symmetric patterns and equal thickness; the metal coils are provided with inductance ports; in the inductor, the first layer of metal coil is spirally wound to the innermost end from one inductance port and then is connected with the other layer of metal coil through an interlayer through hole; the other layer of metal coil is spirally wound to the outermost end; and the upper layer metal coil is interconnected with the lower layer metal coil through the interlayer through hole. Since the mutual inductance between the symmetric upper layer metal and lower layer metal is fully utilized, the inductance of the inductor is effectively improved under the same area condition compared with the inductance of the conventional differential inductor. Both quality (Q) factor and inductance are obviously improved under the same area condition.

Owner:SHANGHAI HUA HONG NEC ELECTRONICS

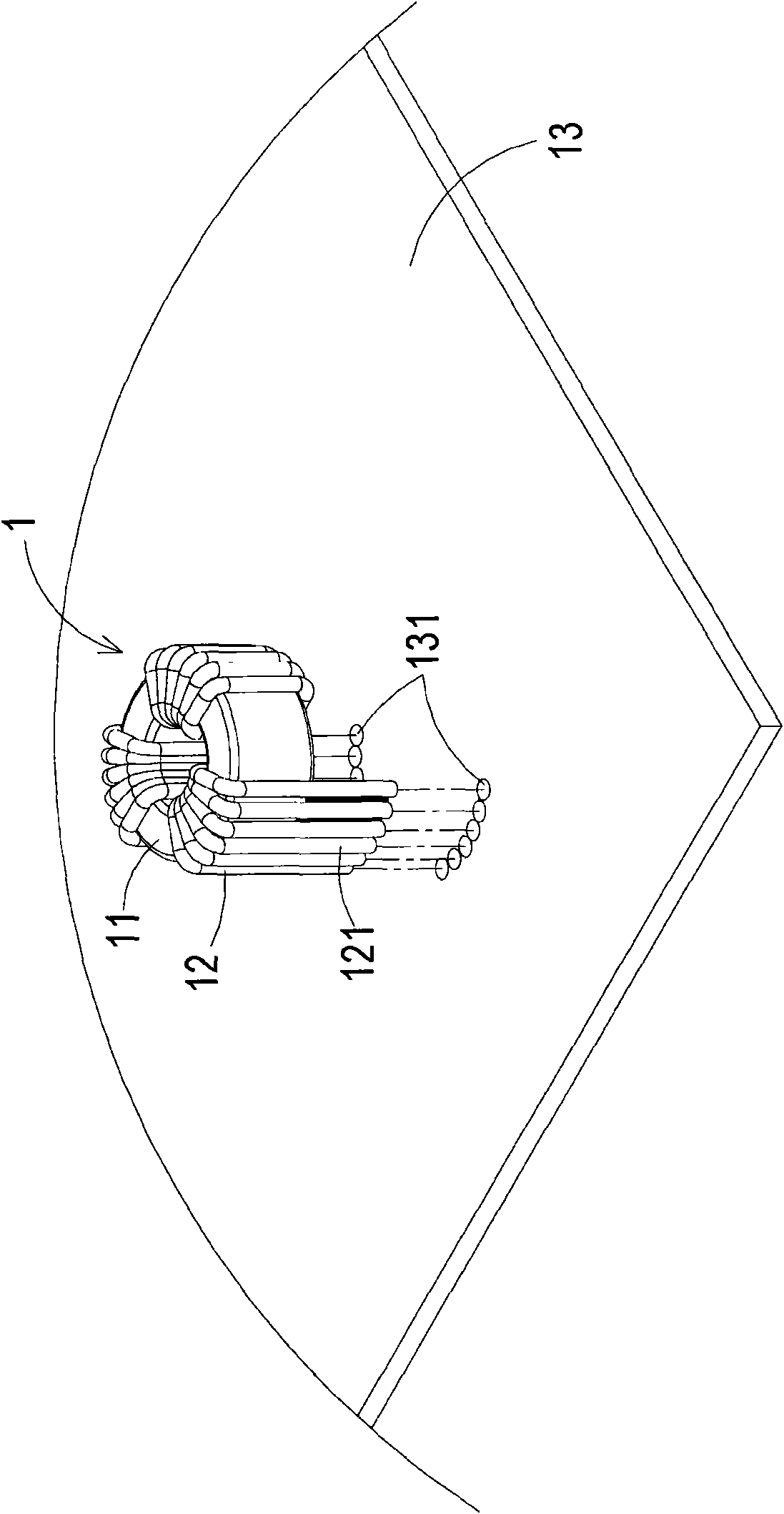

Wireless charging coil assembly

ActiveCN109087798ALower impedanceRaise the sensory valueTransformersTransformers/inductances coils/windings/connectionsEngineeringInductance

A wireless charging coil assembly includes a coil body, and the coil body includes a plurality of conductive coil layers arranged in longitudinal order and dielectric layers arranged between every twoadjacent conductive coil layers; each conductive coil layer includes a plurality of first conductive coil layers and at least one second conductive coil layer, each first conductive coil layer comprises at least one first coil segment, each second conductive coil layer comprises at least one second coil segment, projection of the first coil segment on each first conductive coil layer on the corresponding second conductive coil layer is spliced with the corresponding second coil segment to form a complete coil shape; the first coil segments corresponding to one other of different layers are connected in parallel with one other; the second coil segments corresponding to one other of the different layers are connected in parallel with one other; each of the first coil segments and each of the second coil segments are connected in series with each other. The wireless charging coil assembly of the invention adopts the form of multi-layer resistance coils being in parallel to reduce the impedance, and increases the inductance L through the coil segmentation, so as to improve the wireless charging efficiency.

Owner:NUBIA TECHNOLOGY CO LTD

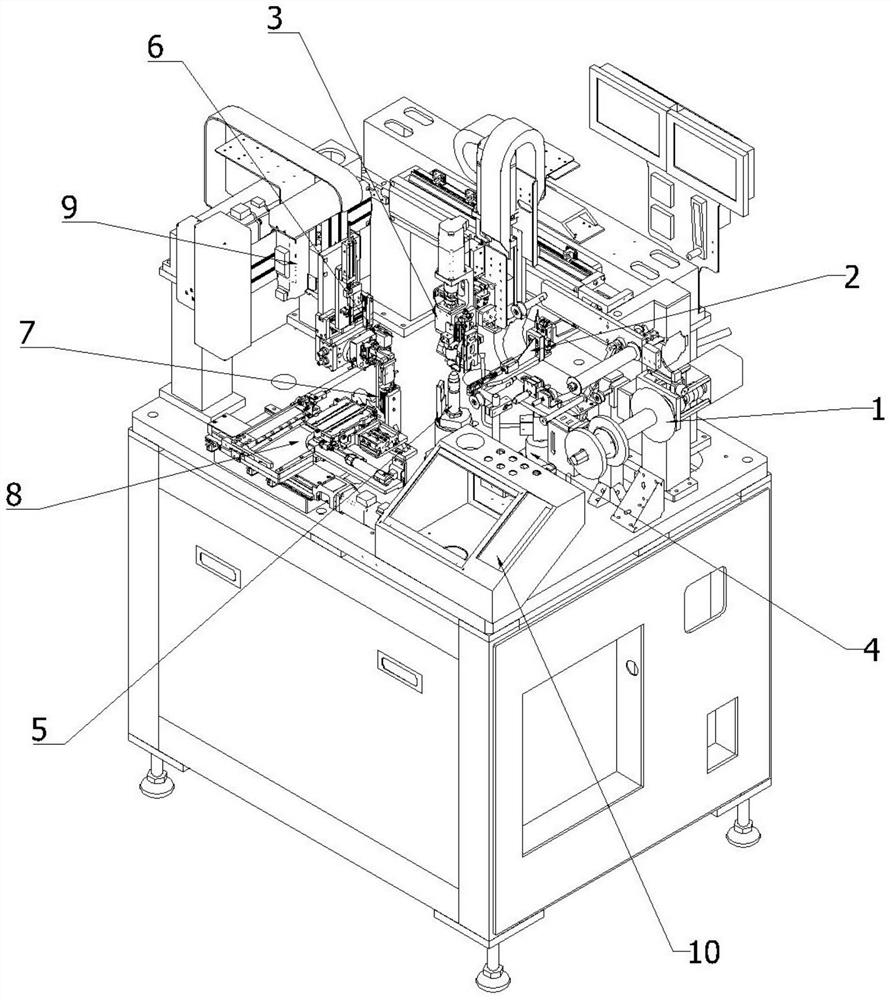

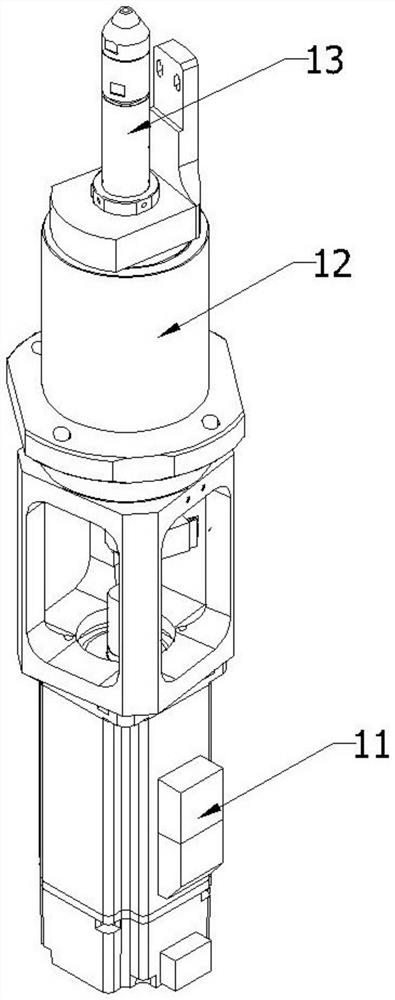

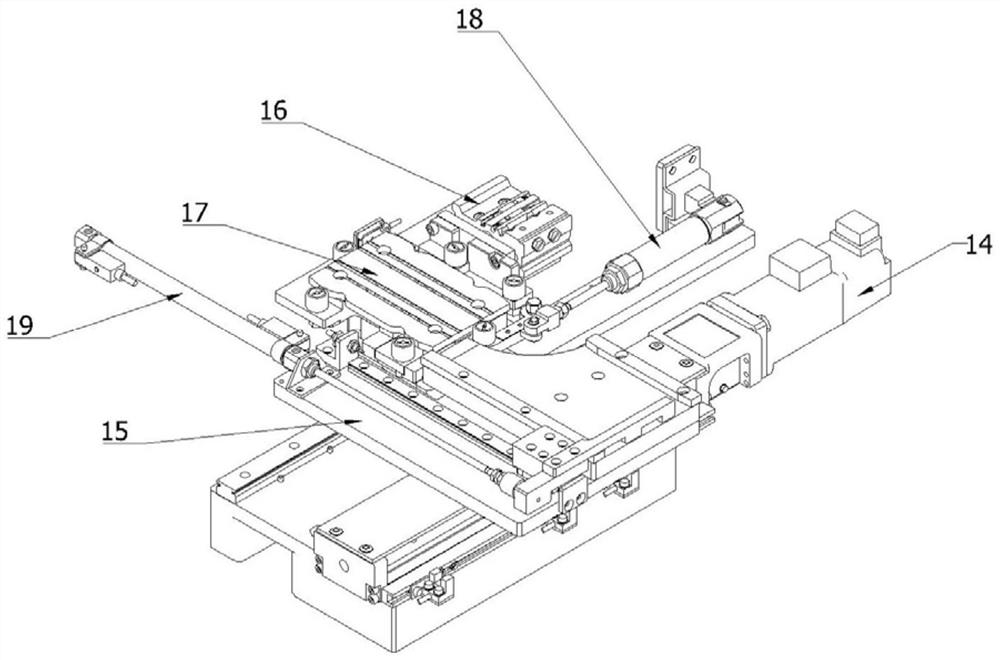

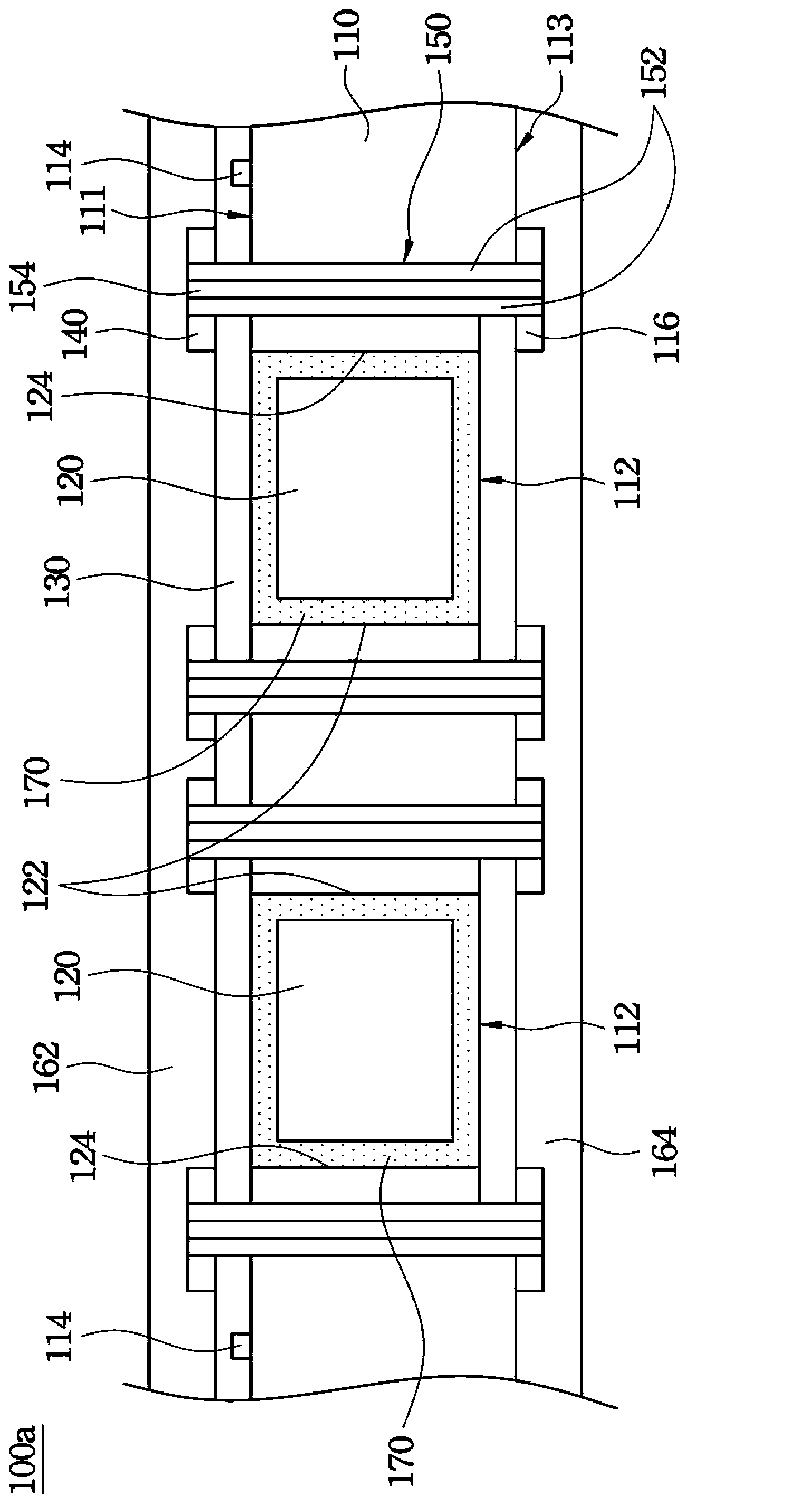

Patch type integrally-formed inductor winding machine

PendingCN112331475AAvoid damageRaise the sensory valueCoils manufactureWinding machineInductor windings

The invention discloses a patch type integrally-formed inductor winding machine. The machine comprises an equipment machine table, a coil forming module is arranged in the middle of the upper end of the equipment machine table, and a jig transferring module, a finished product coil filling module, a waste wire collecting module, a coil shaping module, a coil transferring module, a wire taking module, a hot air conveying module, a wire feeding module and a control system are sequentially arranged in the circumferential direction with the coil forming module as the circle center. The winding machine has the beneficial effects that a copper wire is conveyed to the winding position through the wire taking module, a finished coil is conveyed to the shaping position after winding is completed, redundant copper wires are cut and collected after shaping is completed, the shaped coil is conveyed to the position above the jig, and after the jig is filled and a belt jig is in place, the coil is filled into the jig through the filling module. While the inductance value of the product is improved, the size of the product body is reduced, copper wire damage in the production process is reduced,and the machine table can achieve coil production and assembly to better meet market requirements.

Owner:江苏华磁电子科技有限公司

Inductor and manufacturing method thereof

InactiveCN112614673AEasy to crackReduce DC resistanceTransformers/inductances coils/windings/connectionsInductances/transformers/magnets manufactureElectrical conductorInductor

The invention discloses an inductor and a manufacturing method thereof. The inductor comprises a magnetic core and a conductor, the middle part of the conductor is arranged in the magnetic core, two ends of the conductor are exposed outside the magnetic core, the middle part of the conductor is thicker than the two ends of the conductor, and / or the middle part of the conductor is wider than the two ends of the conductor to reduce the direct-current resistance of the inductor. The manufacturing method comprises the following steps of A, manufacturing the conductor, B, putting the conductor into magnetic powder, and pressing to form an inductor semi-finished product, C, sintering, annealing and curing the inductor semi-finished product, and D, processing the two ends of the conductor, removing redundant parts, and bending the two ends of the conductor. According to the inductor, the middle part of the conductor is thickened and / or widened, so that the direct-current resistance of the inductor can be effectively reduced. In the inductor manufacturing method, through a sintering annealing process, the inductance value of the inductor can be improved, the size of the inductor can be reduced, the loss and heating of the inductor under high-frequency use can be reduced, and the efficiency of the inductor can be improved.

Owner:HENGDIAN GRP DMEGC MAGNETICS CO LTD

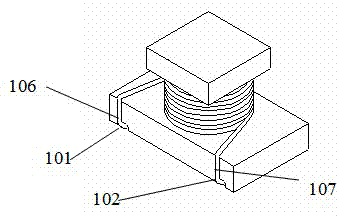

Molding component and manufacturing method thereof

InactiveCN113436830AAvoid breakingAvoid deformationTransformers/inductances casingsTransformers/inductances coils/windings/connectionsCopper wireTransfer molding

The invention relates to a molding component and a manufacturing method thereof, the molding component comprises a hollow coil, a magnetic core, a magnetic plastic package layer and an electrode, the hollow coil is wound on the periphery of the magnetic core, the magnetic core is a pre-sintered magnetic core, and the magnetic plastic package layer is arranged on the periphery of the magnetic core. The magnetic plastic package layer is formed on the hollow coil and the pre-sintered magnetic core in a plastic package mode in a transfer molding or potting mode, and an electrode connected with a lead of the hollow coil is exposed on the outer side of the magnetic plastic package layer. Because the pre-sintered magnetic core is introduced into the molding component, and the magnetic plastic package layer on the coil magnetic core assembly is formed in a transfer molding or potting manner, copper wire damage and deformation and magnetic core fragmentation during a sintering process and cold pressing or hot pressing molding can be effectively avoided; and electrical characteristics such as inductance value and saturation characteristic of a component product can be improved, the product reliability is high, the process is simple, and the cost is low.

Owner:SHENZHEN SUNLORD ELECTRONICS

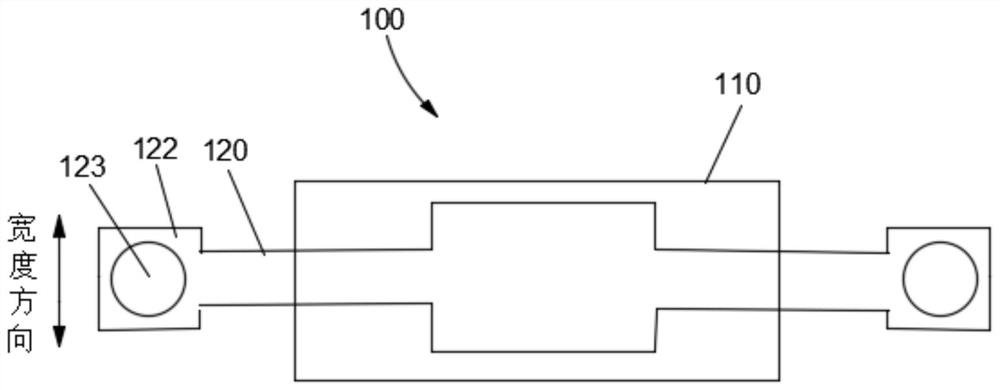

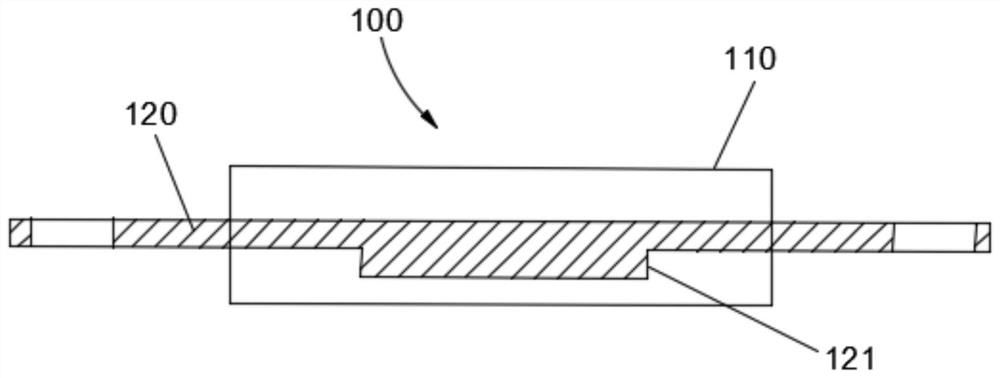

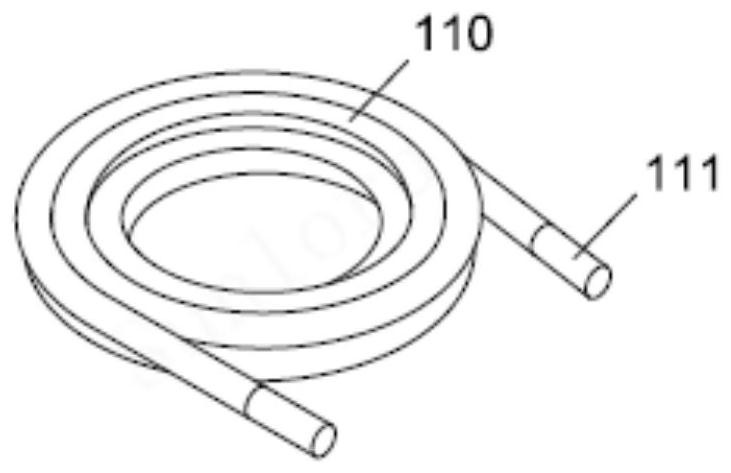

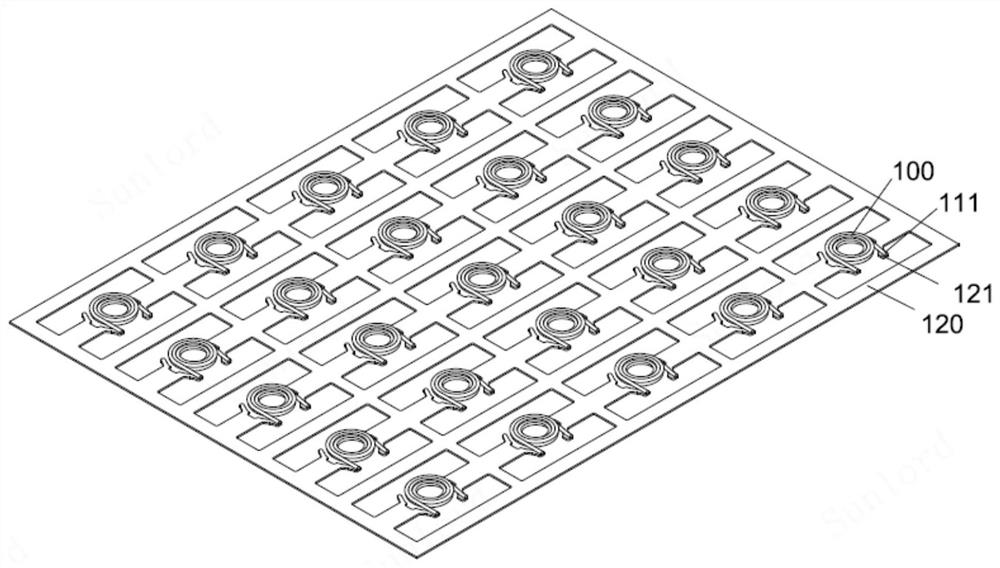

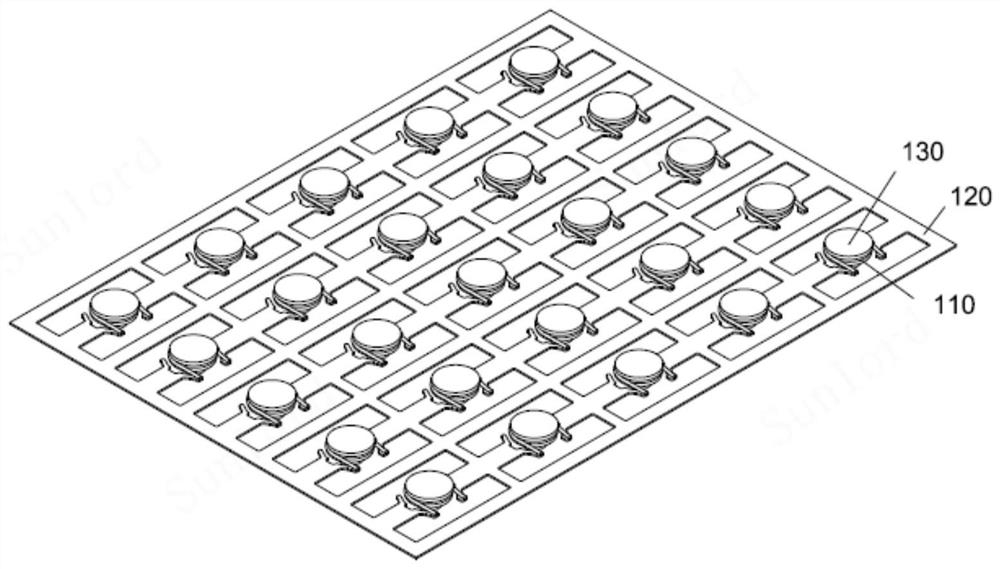

Inductor bar and manufacturing method thereof

InactiveCN112216472AImprove bindingRaise the sensory valueTransformers/inductances coils/windings/connectionsTransformers/inductances noise dampingElectrical conductorMagnetic media

The invention discloses an inductor bar and a manufacturing method thereof, and the inductor bar comprises at least one magnetic core; at least two conductors arranged on the magnetic core, wherein each conductor comprises a base part and an electrode part, the surface of each base part is insulated, and the conductors are assembled with the magnetic core through the base parts; a magnetic plasticpackage layer arranged on the magnetic core and the conductors, wherein the magnetic core and the conductor are both located in the magnetic plastic package layer, the magnetic core and the conductorare attached to the magnetic plastic package layer, and an electrode part of the conductor penetrates through the magnetic plastic package layer to be communicated with the outside. No air gap existsbetween the inner magnetic medium and the outer magnetic medium of the inductor bar, so that a high inductance value can be maintained under the condition of high current, almost no noise is generated under high frequency, and the reliability is high.

Owner:SHENZHEN SUNLORD ELECTRONICS

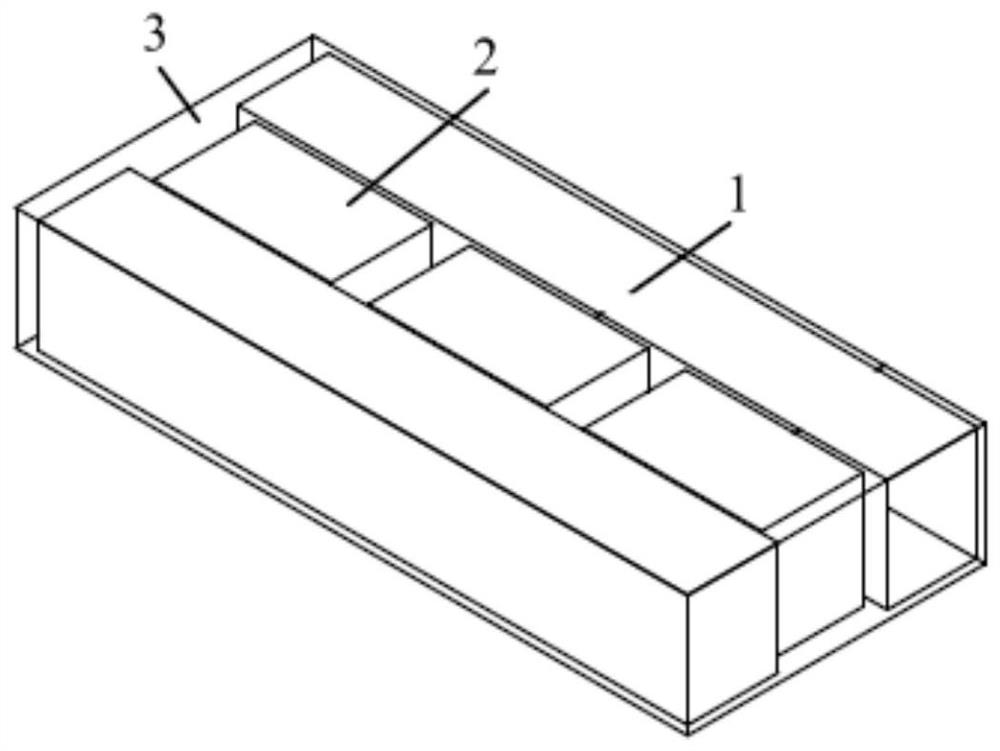

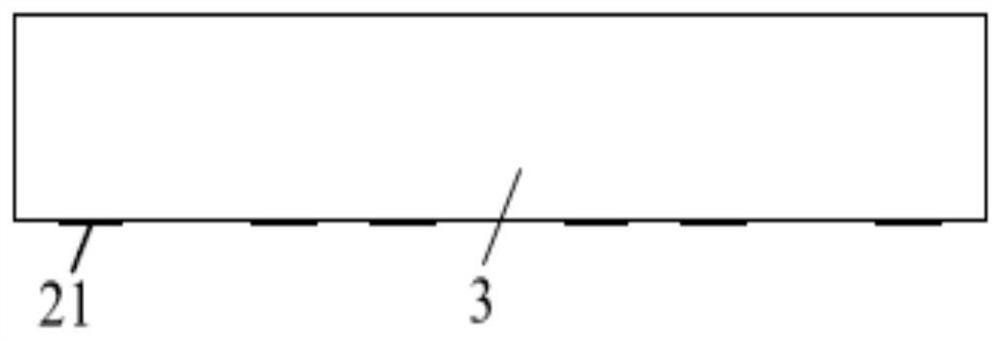

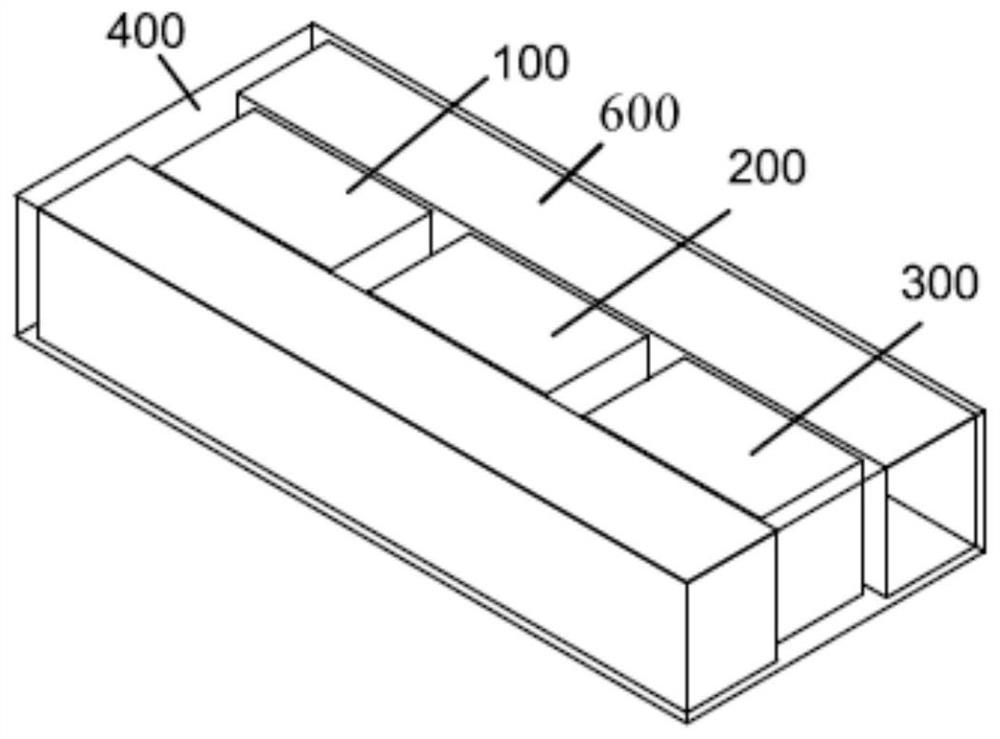

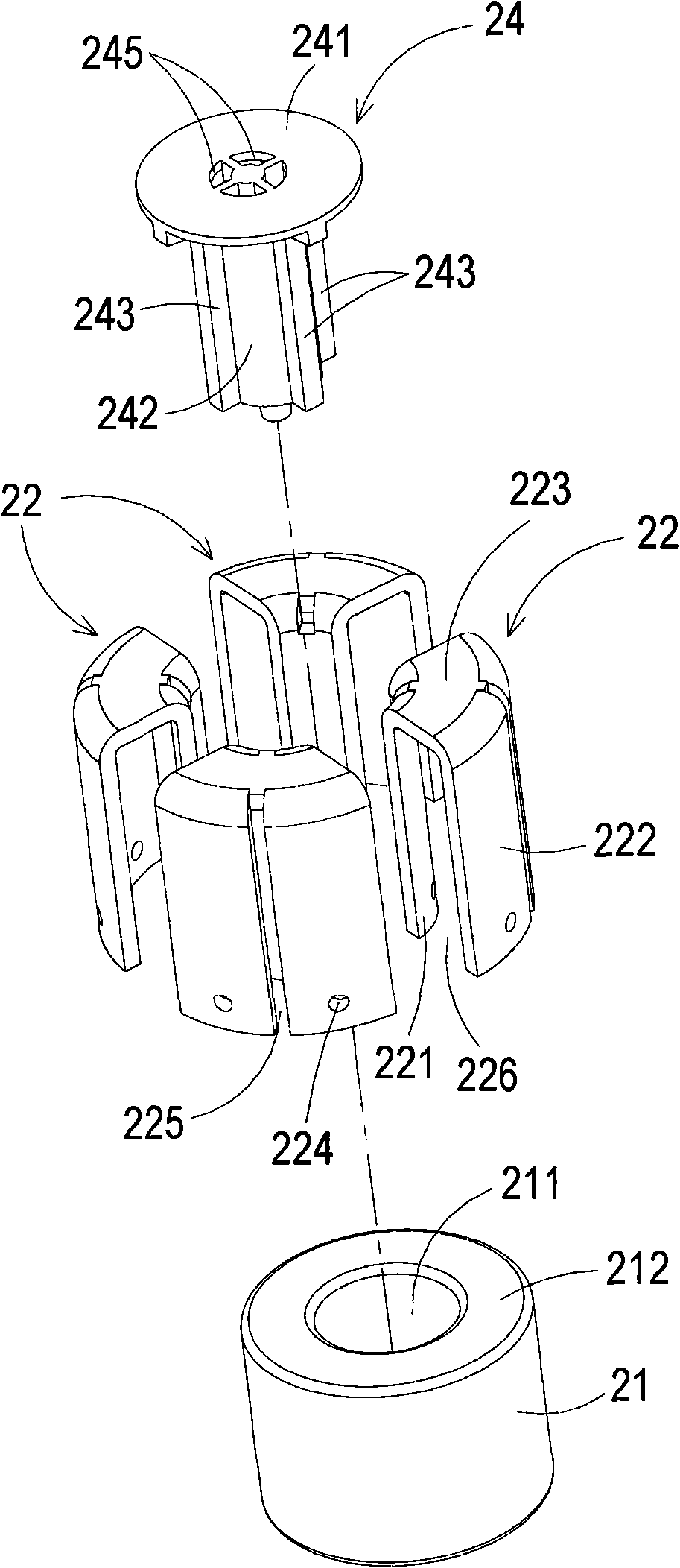

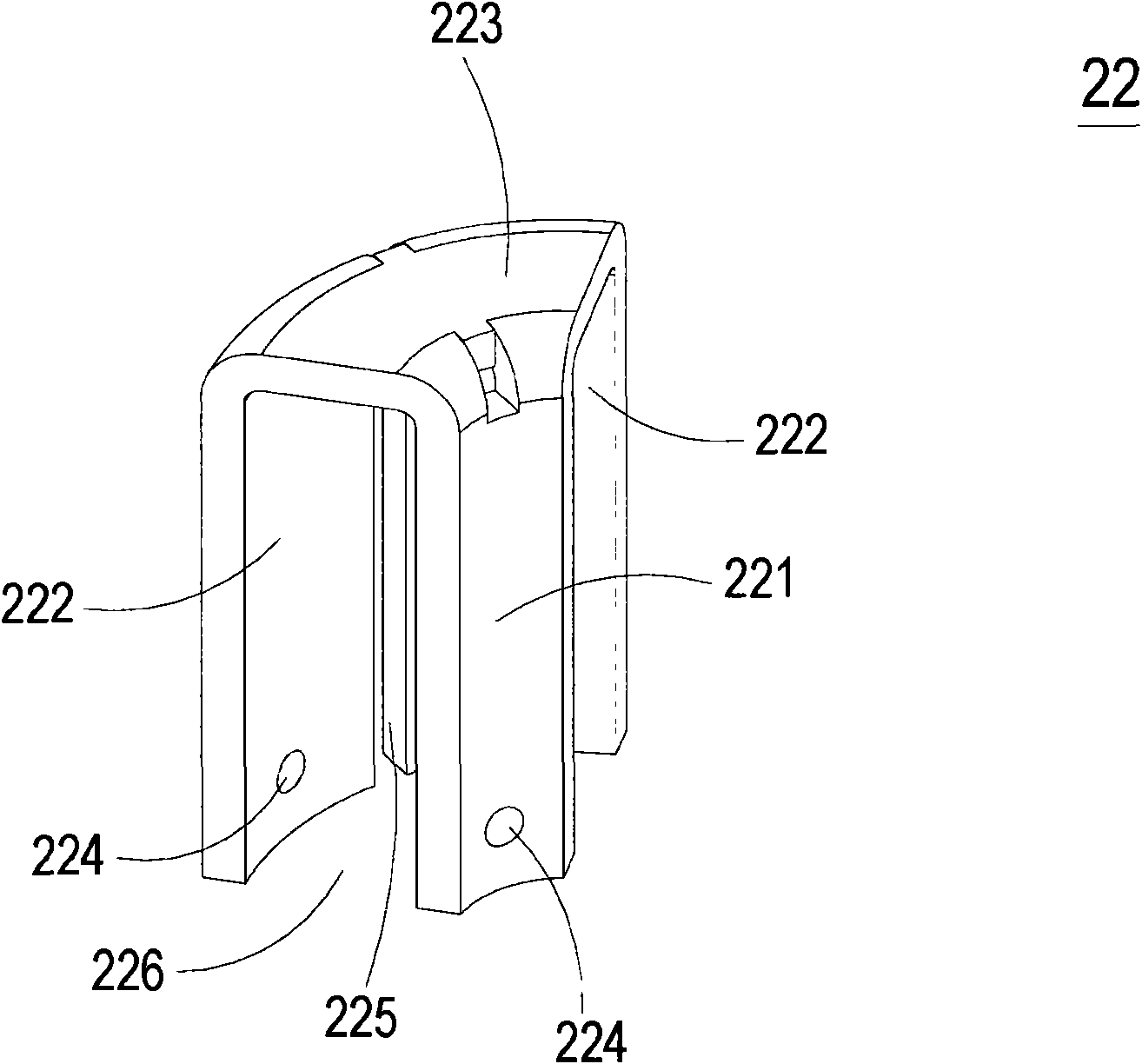

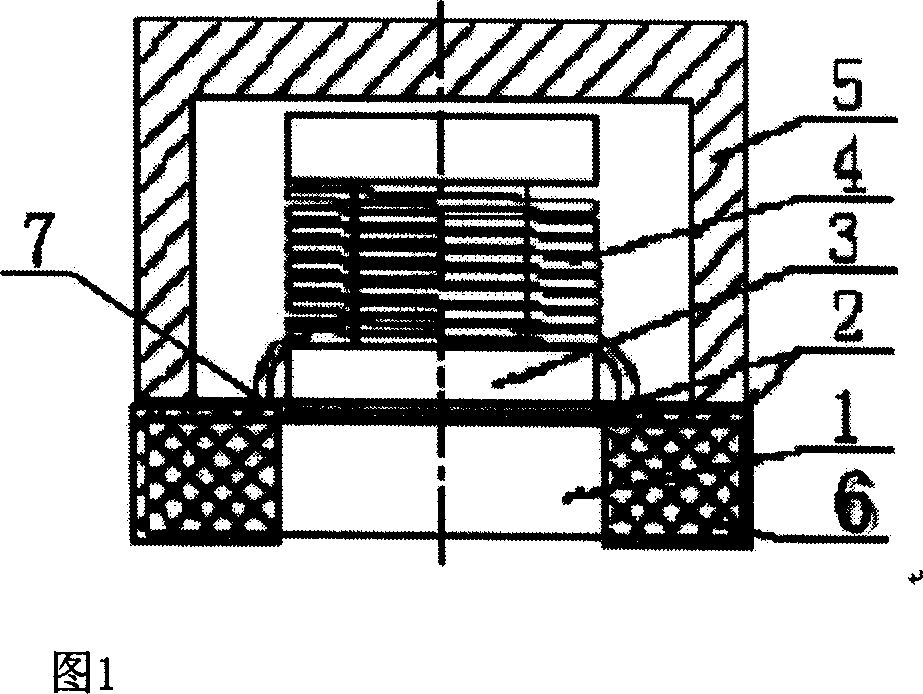

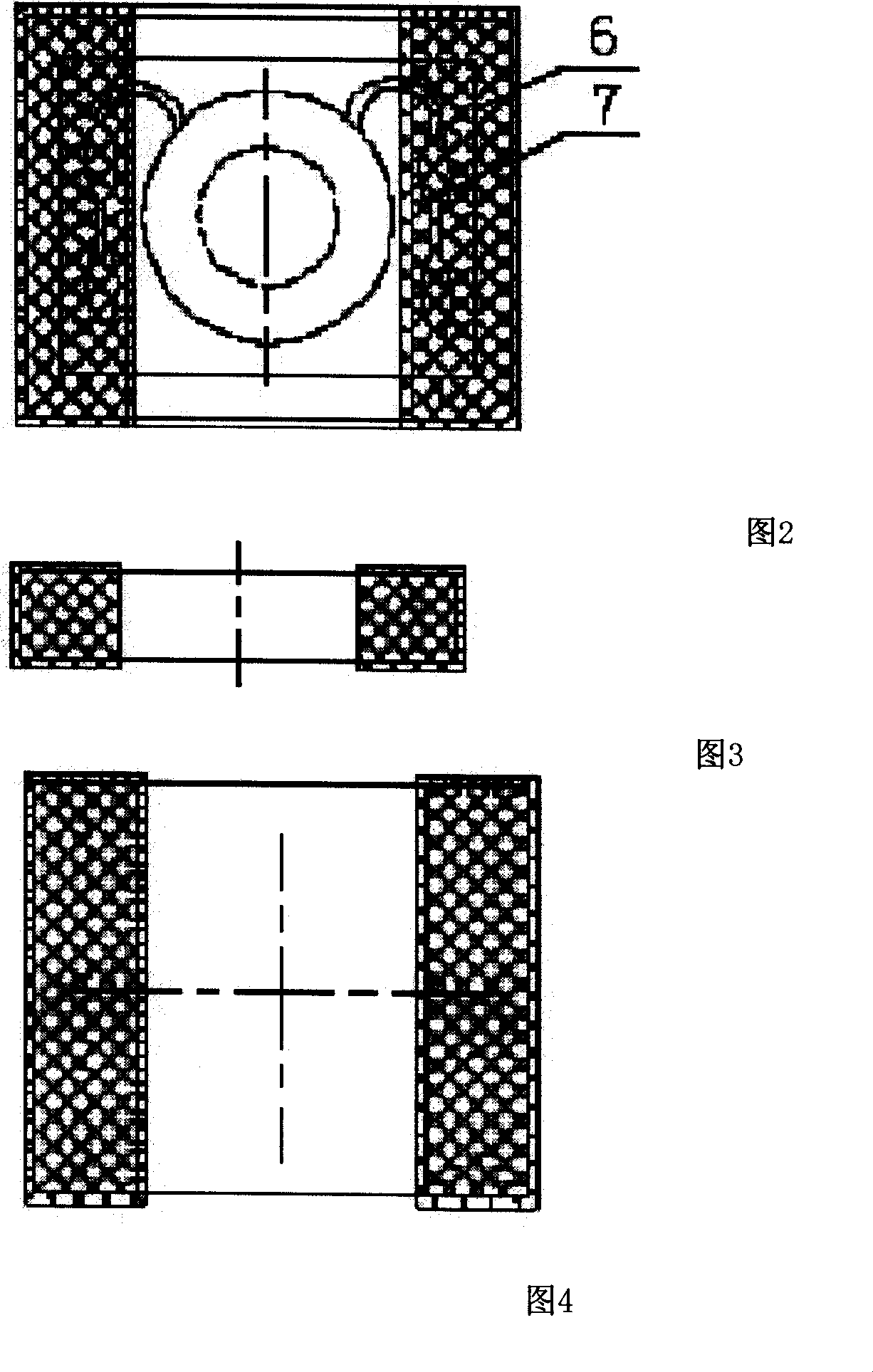

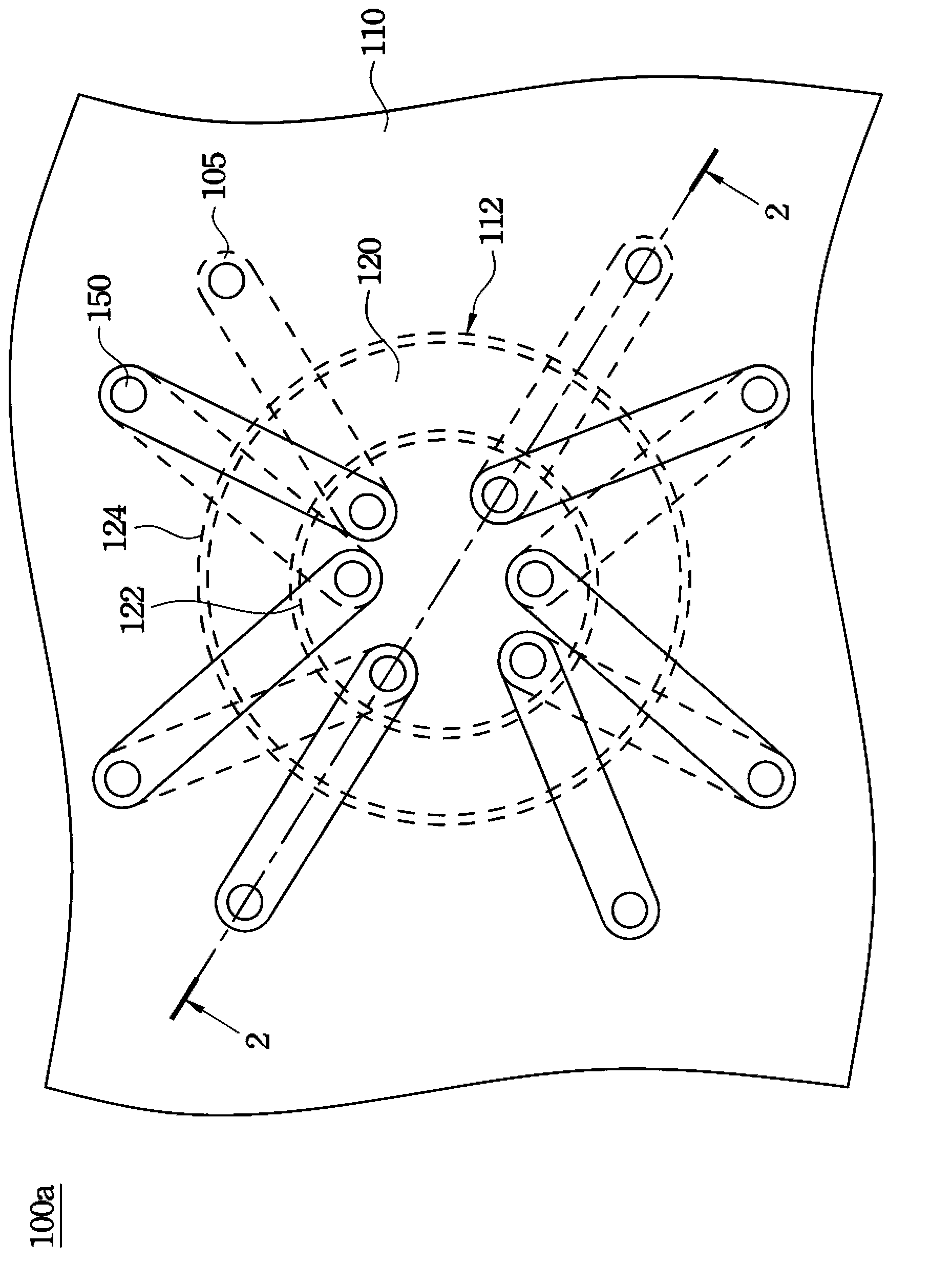

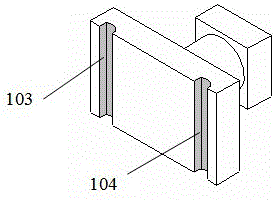

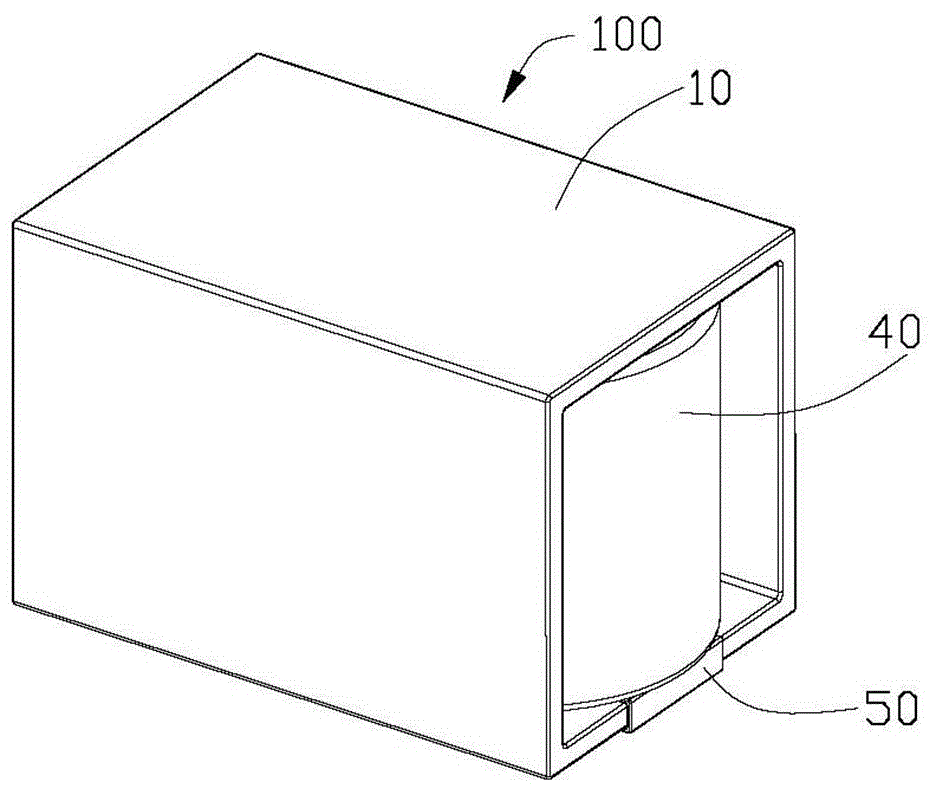

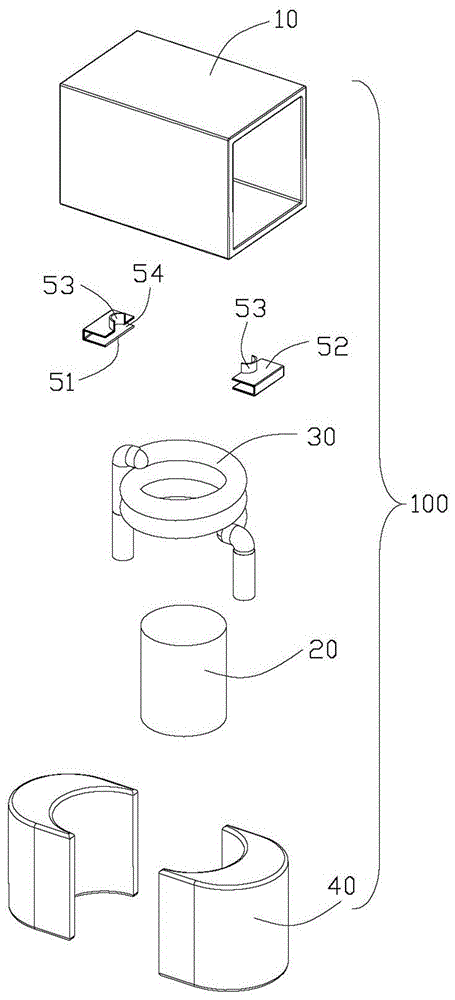

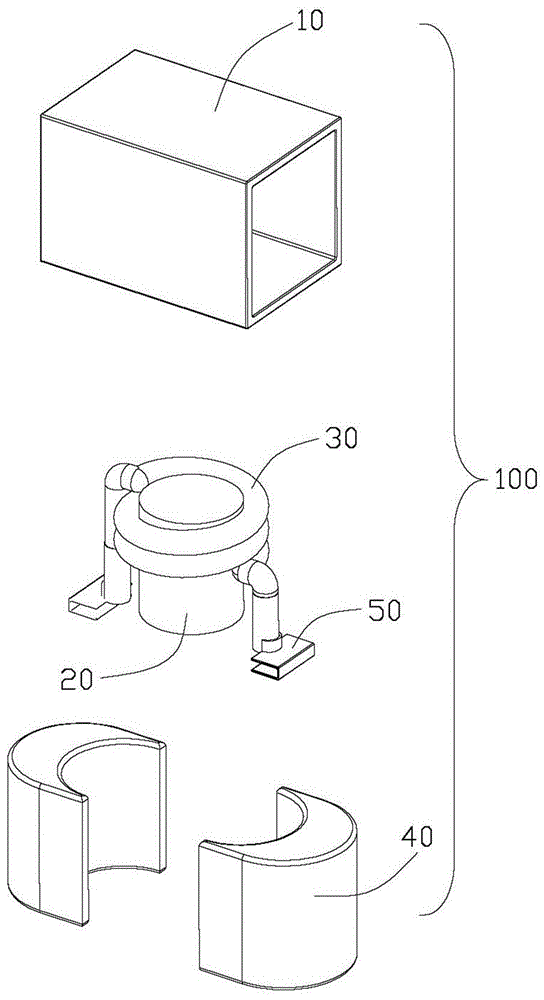

Magnetic assembly and assembling method thereof

InactiveCN101944425ARaise the sensory valueIncreasing the thicknessPrinted circuit assemblingInductances/transformers/magnets manufactureEngineeringElectrical and Electronics engineering

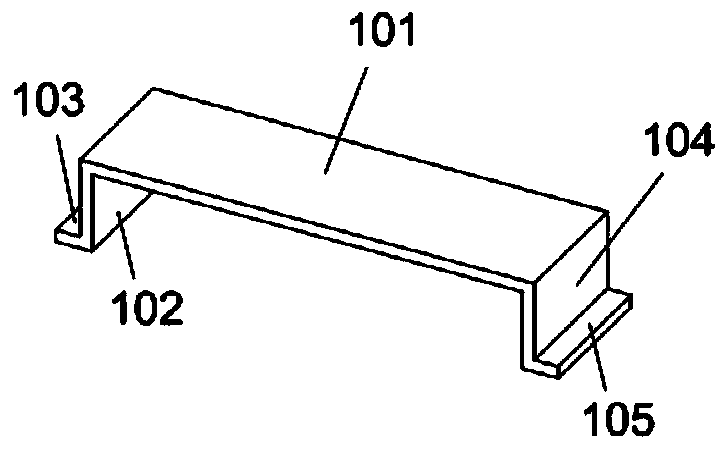

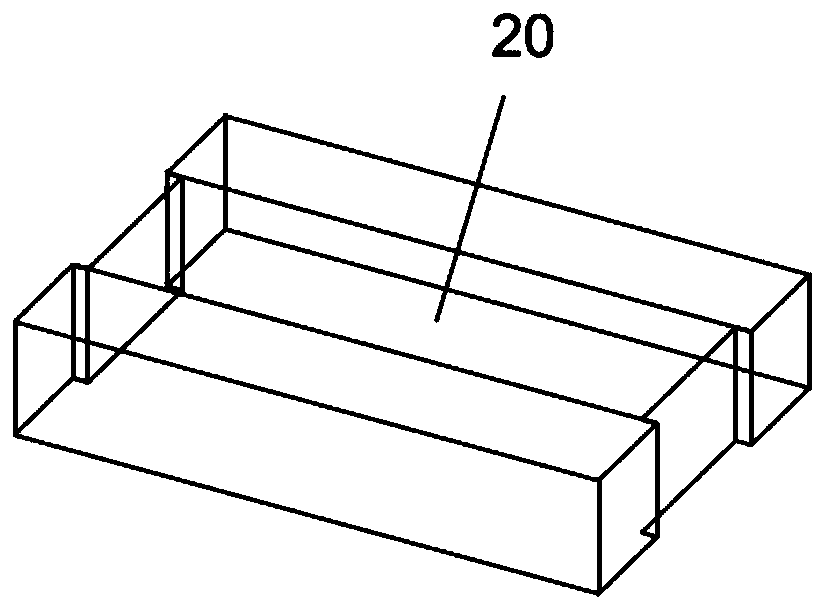

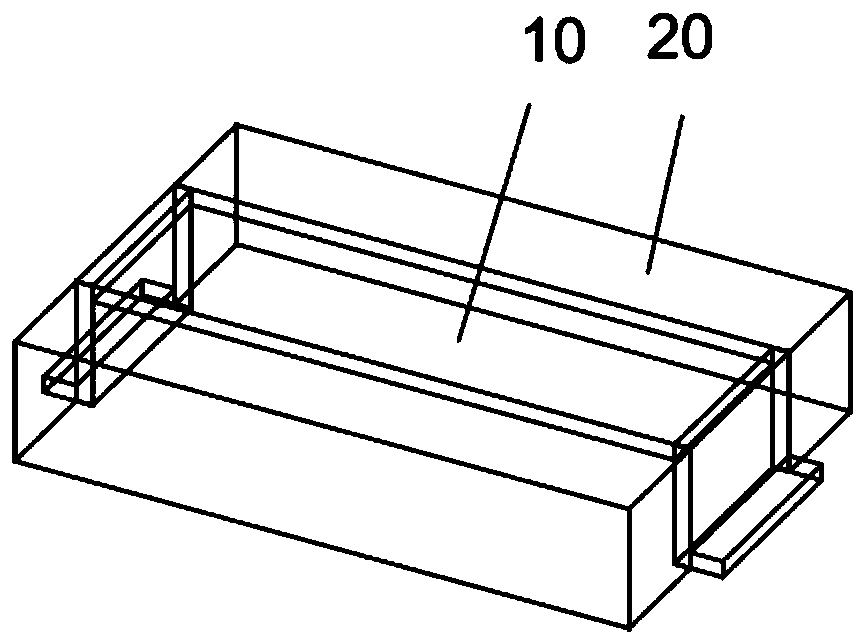

The invention discloses a magnetic assembly and an assembling method thereof. The magnetic assembly at least comprises an iron core, a circuit board and a plurality of conductive elements, wherein the circuit board is provided with a plurality of conductive regions; each conductive element is provided with a first end part, a second end part and a connecting part for connecting the first end part and the second end part; the plurality of conductive elements are respectively arranged across the iron core; and the first end part and the second end part of each conductive element are respectively connected to the two adjacent conductive regions so that the plurality of conductive elements and the plurality of conductive regions form a plurality of numbers of rings on the iron core. The magnetic assembly and the assembling method thereof ensure that the plurality of conductive elements and the plurality of conductive regions form the plurality of numbers of rings on the iron core, and the numbers of sensing rings formed on the iron core can be increased with easy assembly. In addition, the cross sections of the conductive elements arranged on the iron core are same as the public known coils, and sensing values of the magnetic assembly is increased through increasing the thickness of the conductive elements.

Owner:DELTA ELECTRONICS INC

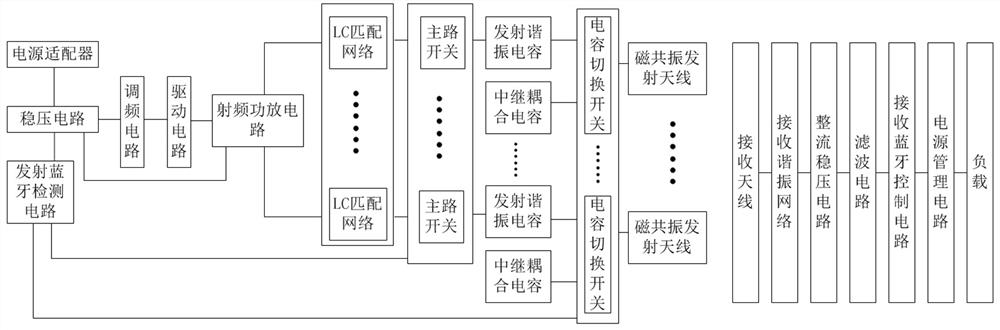

Three-dimensional polyhedral magnetic resonance wireless charging transmission device based on multi-antenna switching

ActiveCN113497492ASmall sizeLarge size differenceBatteries data exchangeElectric powerRadio frequency energyMicro devices

The invention discloses a three-dimensional polyhedral magnetic resonance wireless charging transmission device based on multi-antenna switching. The three-dimensional polyhedral magnetic resonance wireless charging transmission device comprises a magnetic resonance wireless electric energy transmitting module, a plurality of magnetic resonance transmitting antennas, a plurality of receiving antennas and a magnetic resonance wireless electric energy receiving module which are connected in sequence, the magnetic resonance wireless electric energy transmitting module is used for converting a direct-current power supply into the radio frequency energy and controlling a working mode; the magnetic resonance transmitting antenna is used for converting the radio frequency energy into a reactance field distributed in space; the receiving antenna is used for converting the reactance field into the radio frequency energy; and the magnetic resonance wireless electric energy receiving module is used for converting the radio frequency energy into a direct current power and charging or supplying power to a load. According to the present invention, the transmitting antennas are multiple groups of antennas, when one antenna is used as a main transmitting antenna, other antennas are used as relay coupling antennas, the transmitting and receiving antennas all adopt a three-dimensional multi-layer winding structure, the size difference of the transmitting and receiving antennas is larger, and the antenna is suitable for charging and supplying power to a micro device which is limited in cruising ability and cannot be supplied with power in a wired manner.

Owner:CHENGDU SPROUTING TECH CO LTD

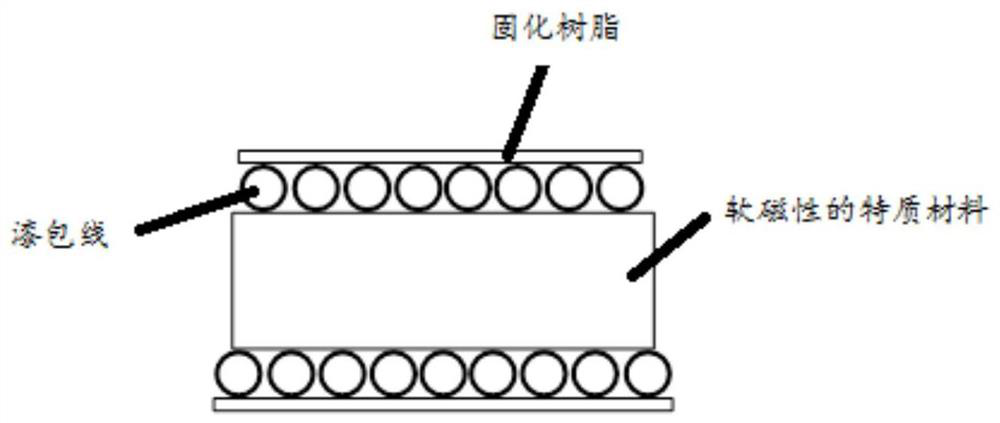

Dual welding spots inductor in high frequency packaged by ceramics

InactiveCN1959875AAvoid Damage Failure SituationsAvoid influenceTransformers/inductances casingsInductances/transformers/magnets manufactureHigh densityInductor

Method for manufacturing the disclosed inductor in high frequency includes steps: fixing up magnetic core on the ceramic base plate with leading out ends of metal; next, winding double lacquered wires on magnetic core; then, soldering double lacquered wires on leading out ends of metal so as to form duplex soldered points; finally, using ceramic package to enclosure protect to protect double lacquered wires and soldered points. Features are: reasonable design configuration, small size, large value of inductance, and high Q value. Being suitable to electronic products stuck assembled in high density and in mini type. Being reached to astronavigation level, the product possesses high reliability.

Owner:VONTRON TECH CO LTD

A preparation method for producing low-loss powder for integrated molding inductors

ActiveCN111063501BReduce eddy current lossReduce lossTransportation and packagingMetal-working apparatusIron powderEngineering

Owner:深圳市艺感科技有限公司

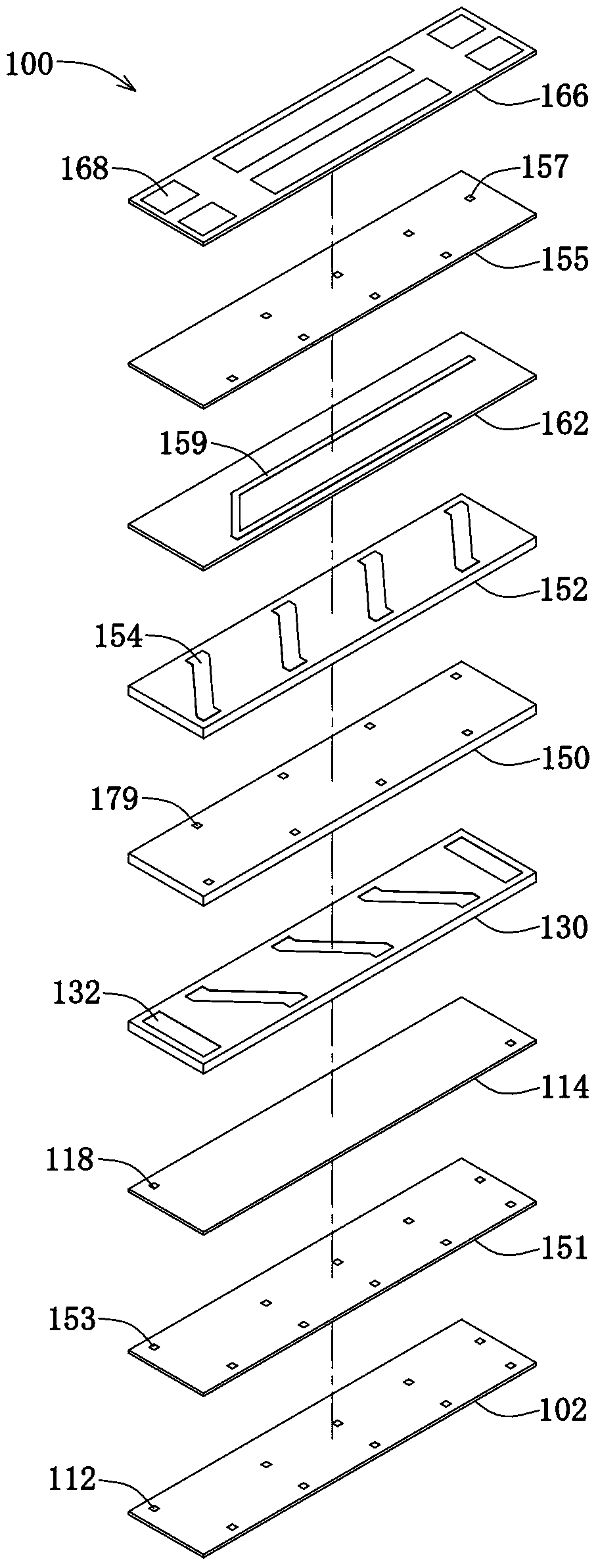

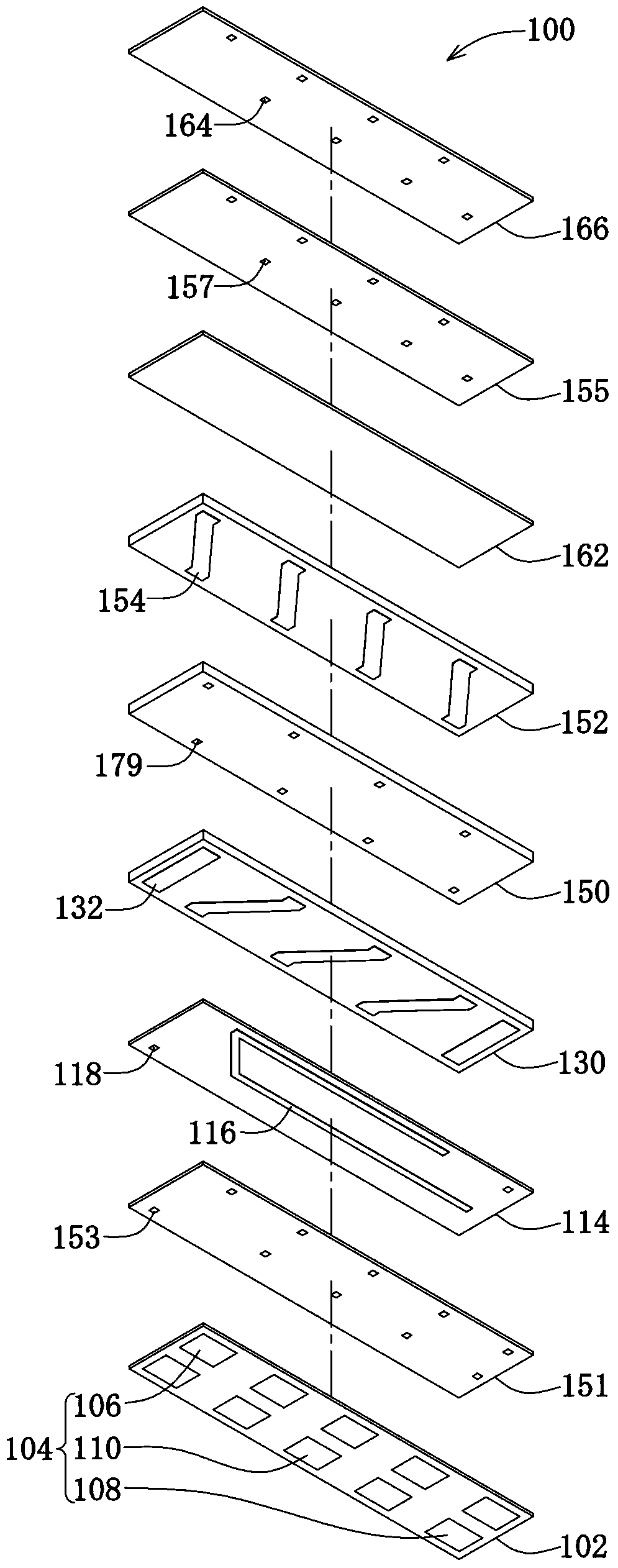

Circuit board packaging structure and manufacturing method thereof

ActiveCN103813632AAvoid damageLow costPrinted circuit assemblingPrinted circuit non-printed electric components associationConductive channelEngineering

The invention discloses a circuit board packaging structure and a manufacturing method thereof. The circuit board packaging structure comprises a substrate with opposite first and second surfaces, an annular magnetic element, an adhesive layer, a plurality of conductive parts and a plurality of conductive channels. The first surface and the second surface are provided with a plurality of first metal parts and a plurality of second metal parts, respectively. An annular groove is formed in a position, not covered with the first metal part, on the first surface. The annular magnetic element is arranged in the annular groove. The adhesive layer is located on the first surface and covers the first metal parts and the annular magnetic element. The conductive parts are formed on the adhesive layer and correspond to the second metal parts, respectively. The conductive channels penetrate through the conductive parts, the adhesive layer and the substrate, and are located in the inner wall and outside the outer wall of the annular groove, respectively. Each conductive channel is provided with a conductive film for electrically connecting each conductive part and the corresponding second metal part.

Owner:TRIPOD WUXI ELECTRONICS

Molded power inductor element and manufacturing method

ActiveCN102856037BGood electrical performance consistencyNot easy to shiftTransformers/inductances coils/windings/connectionsTransformers/inductances magnetic coresShell moldingMiniaturization

The invention discloses a power inductance element formed by molding. The power inductance element comprises a prefabricated magnetic core, a coil and a magnetic plastic package layer, wherein the coil is placed on the prefabricated magnetic core; the magnetic plastic package layer is formed by molding and is used for covering the magnetic core and the coil; and an electrode connected with the coil is exposed. The invention also discloses a method for manufacturing the power inductance element formed by molding. The method comprises the following steps of: a, prefabricating the magnetic core and placing the coil on the prefabricated core; and b, covering the magnetic plastic package layer on the magnetic core and the coil by virtue of molding and exposing the electrode connected with the coil. The power inductance product has the advantages of thinning, miniaturization and high reliability.

Owner:SUNLORD (SHANGHAI) ELECTRONICS CO

Communication module

InactiveCN106207383ASmall sizeRaise the sensory valueAntenna supports/mountingsElectrical conductorMaterials science

An embodiment of the invention discloses a communication module. The communication module comprises a magnetic core structure, and a first ceramic body layer and a second ceramic body layer which are arranged on the opposite two sides of the magnetic core structure, and at least one integrated circuit chip, wherein the magnetic core structure comprises a coil conductor pattern; the first ceramic body layer comprises multiple first welding pad electrodes; the second ceramic body layer comprises multiple second welding pad electrodes; each first welding pad electrode comprises a first feeding welding pad electrode, a second feeding welding pad electrode and multiple dummy welding pad electrodes; the first feeding welding pad electrode and the second feeding welding pad electrode are electrically connected with the coil conductor pattern of the magnetic core structure; and the integrated circuit chip is arranged on the second ceramic body layer, wherein the integrated circuit chip comprises at least one jointing pad which is jointed with a part of the second welding pad electrodes. By adoption of the technical scheme provided by the embodiment of the communication module, the dimension of the communication module can be greatly reduced; and the communication module can be widely applied to wearable products.

Owner:INPAQ TECH

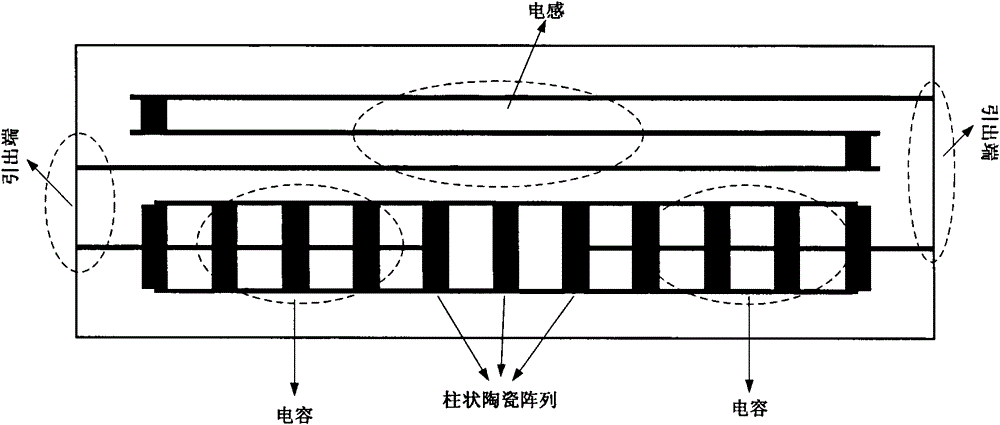

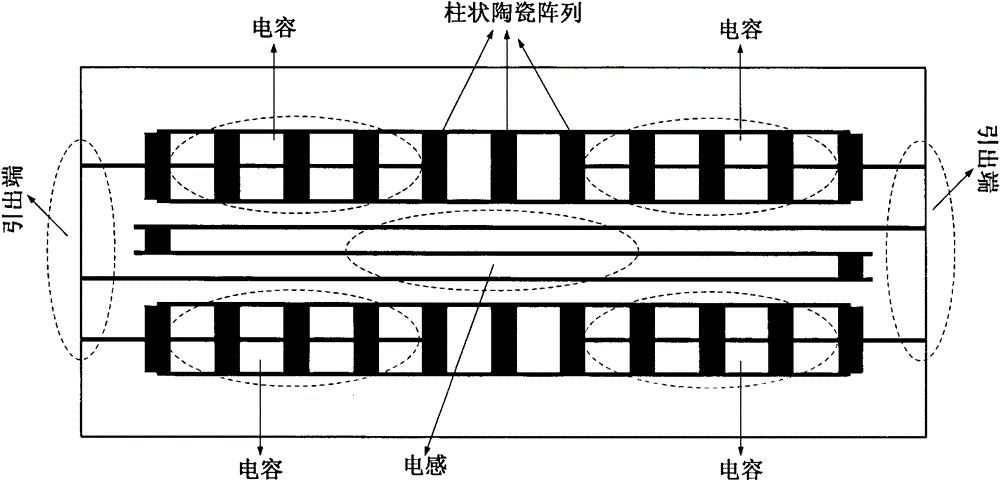

Laminated sheet type filter and preparation method thereof

InactiveCN101951237BRaise the sensory valueLower equivalent series resistanceMultiple-port networksDielectricCapacitance

The invention discloses a laminated sheet type filter and a preparation method thereof, belonging to the technical field of electron component. The filter is formed by compounding a laminated sheet type capacitance and a laminated sheet type magnetic core inductance, wherein the laminated sheet type capacitance is laminated and sintered by multiple layers of ferrite diaphragms of which the surface is printed with conductor wires, composite medium material is arranged between the terminal electrode contained by the laminated sheet type capacitance and a ground electrode, and the composite medium material comprises ferrite material and columnar ceramic arrays distributed in the ferrite material. The preparation method comprises the following steps: burdening, casting, pulping, forming arrays / interconnecting holes, filling ceramics / conductor paste, printing conduction band, laminating, equalizing pressure of hot water, cutting, burning, blocking and the like. The invention increases the equivalent dielectric constant in common ferrite structure by adding the columnar ceramic array structure in the capacitance part of the laminated sheet type filter, improves Q value and capacity and effectively lowers the off frequency of the filter and improves the out of band rejection characteristic of the filter.

Owner:成都成电电子信息技术工程有限公司

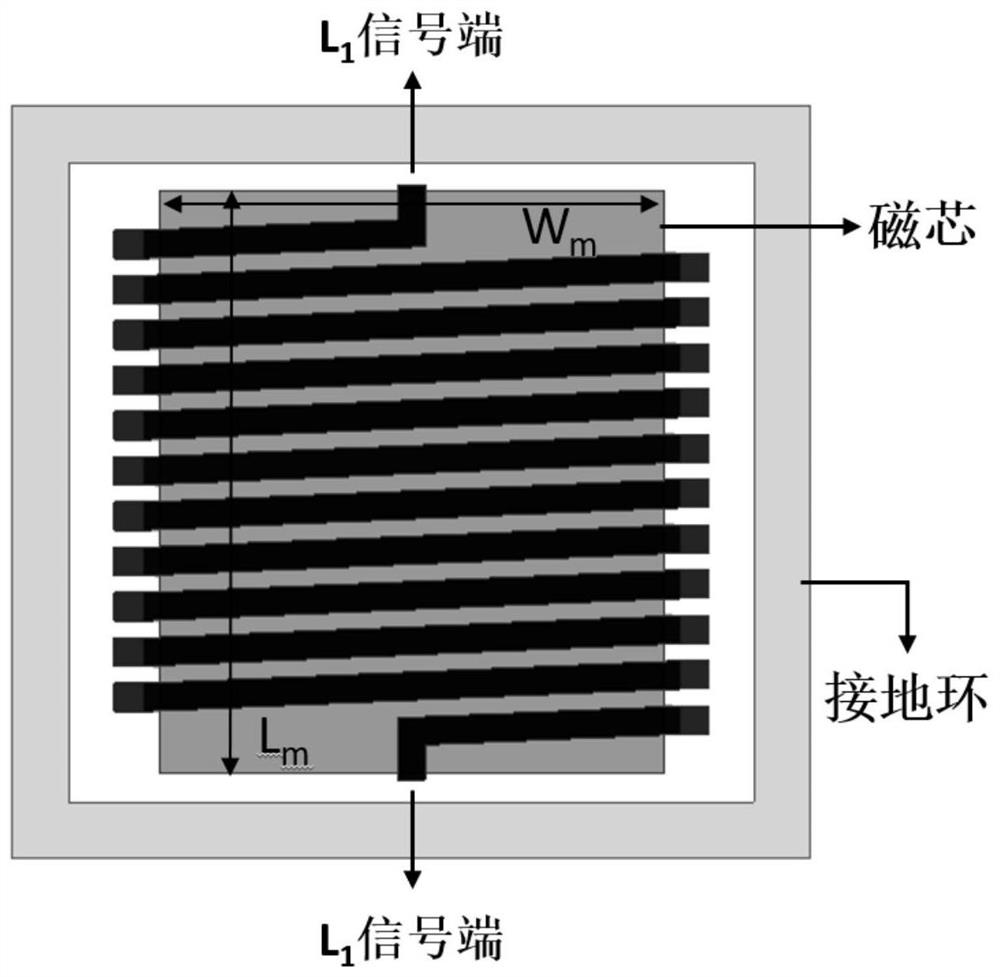

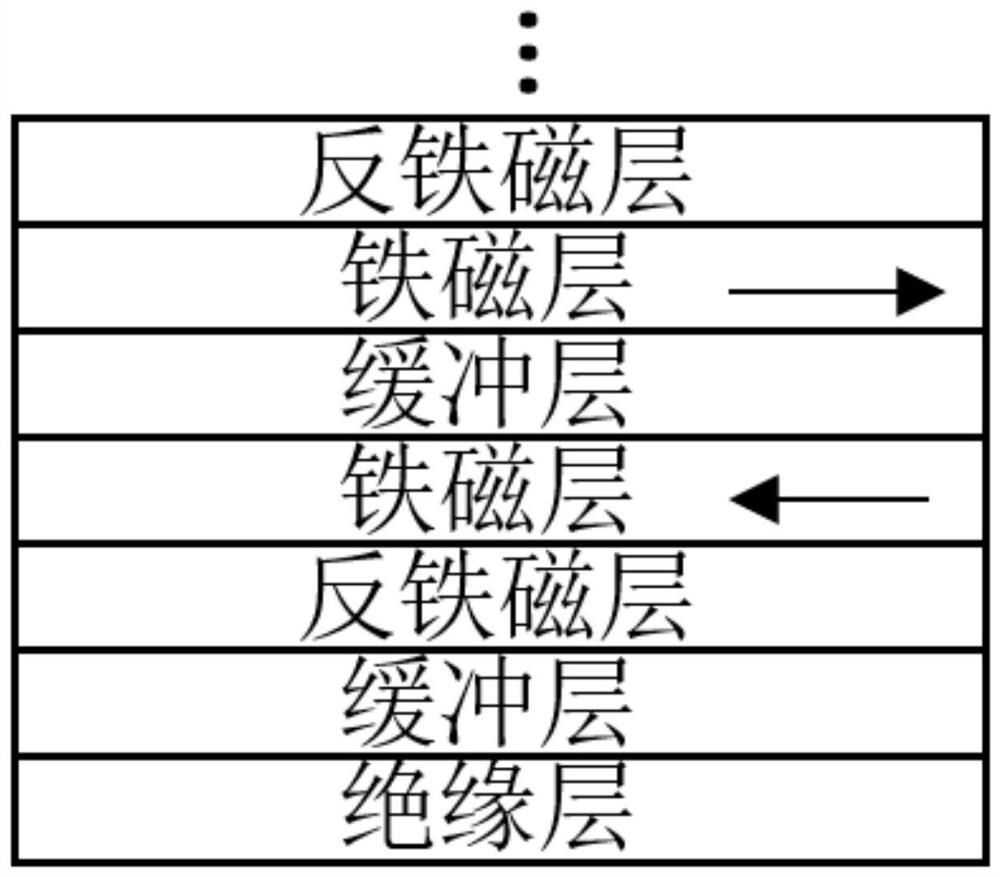

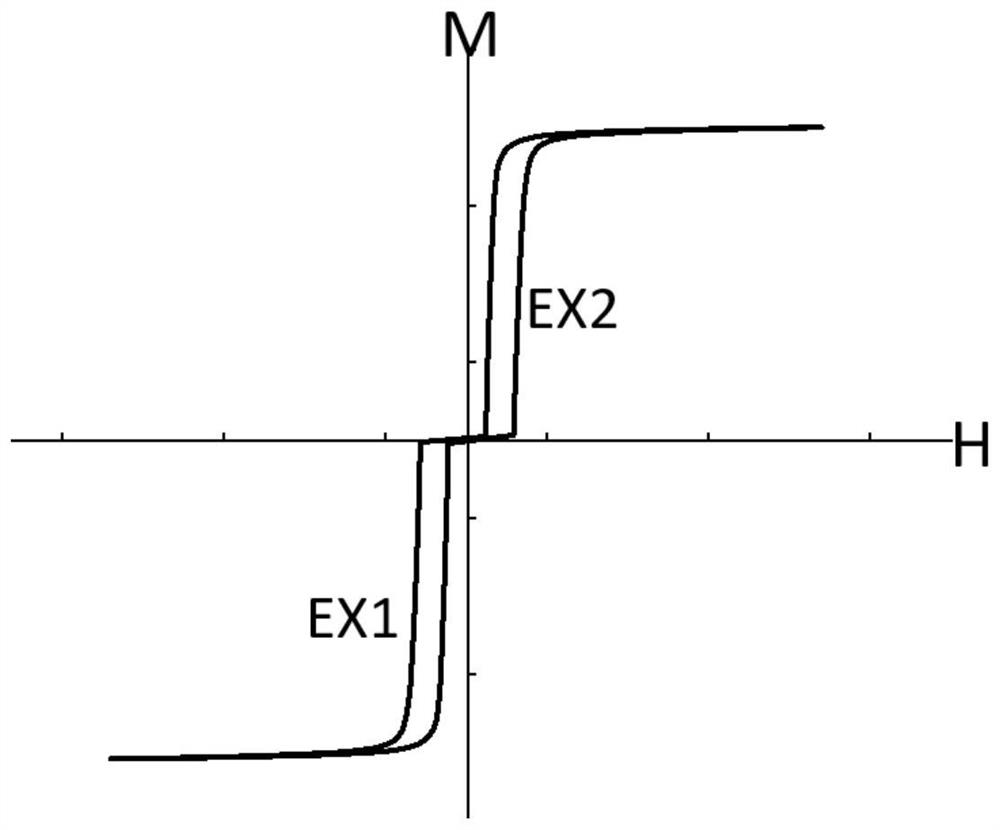

On-chip magnetic core power inductor with inductance value changing along with working current

PendingCN113327749AReduce sensitivityRaise the sensory valueTransformers/inductances casingsTransformers/inductances magnetic coresEngineeringMechanical engineering

The invention belongs to the technical field of passive integrated devices, and particularly provides an on-chip magnetic core power inductor with an inductance value changing along with working current. The inductor is applied to a switching power supply to solve the problem that the switching power supply cannot keep low ripple current and good transient response capability at the same time, and does not need additional components or control circuits. In the invention, an anisotropic magnetic core film adopts an [insulating layer / lower buffer layer / lower antiferromagnetic layer / lower ferromagnetic layer / upper buffer layer / upper ferromagnetic layer / upper antiferromagnetic layer]n multi-layer film structure, and the magnetic core film has lower magnetic conductivity in a low field and higher magnetic conductivity in a high field by utilizing the effect of an anti-parallel exchange bias field between layers of the magnetic core film; when the direct current bias of the inductor is relatively high, the inductor has a relatively large inductance value, so that the ripple current is reduced; and when the power supply is in a turn-on (turn-off) state, the current value on the inductor is relatively small, the inductance value is relatively low, and the transient response capability is improved.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

an inductor

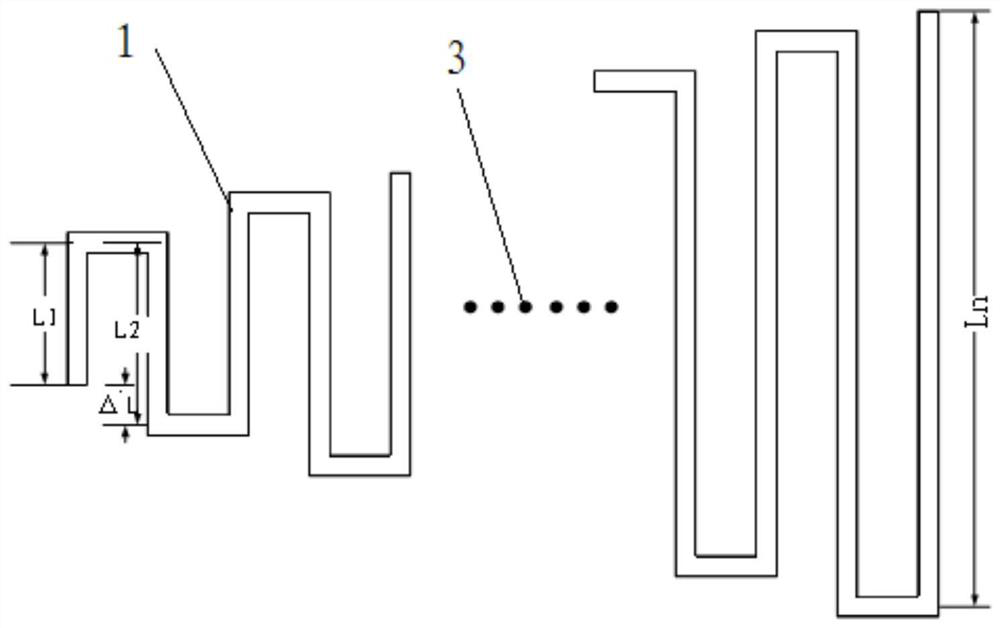

ActiveCN109585139BRaise the sensory valueReduce volumeTransformers/inductances coils/windings/connectionsInductance with magnetic coreInductorBroadbanding

The present invention provides an inductor. The inductor comprises a core substrate; a wire periodically reciprocally laid on the chip substrate by taking a straight line on the chip substrate as an axle wire, wherein the two ends of the wire are respectively provided with leading-out terminals. The technical problems are solved that an inductor uses many magnetic materials for loading, a large induction value cannot be achieved in the broadband application, the core volume is large and the magnetic loss is large in the prior art. The inductor can use few magnetic materials to reduce the high-frequency magnetic loss, can optimize the high-frequency performance, can greatly reduce the inductor size through adoption of a special coiling method, is convenient to integrate, achieves broadbandinduction on the chip and can be suitable for large-scale production.

Owner:INST OF MICROELECTRONICS CHINESE ACAD OF SCI

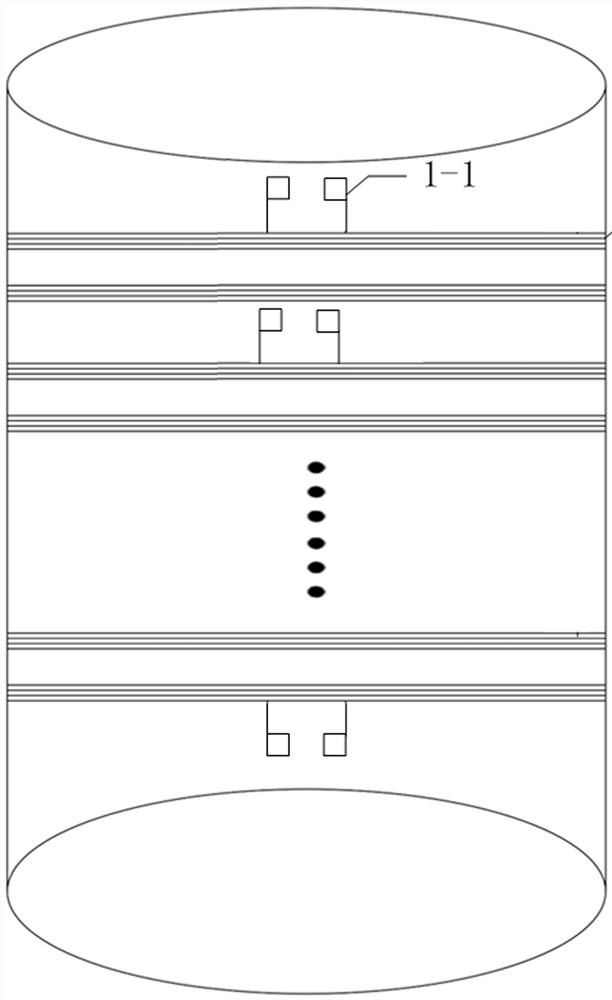

A cylindrical inductor and its manufacturing method

ActiveCN107610879BRaise the sensory valueReduce usageTransformers/inductances coils/windings/connectionsCoils manufactureEngineeringInductor

Owner:INST OF MICROELECTRONICS CHINESE ACAD OF SCI

a differential inductor

ActiveCN104810349BImprove electrification abilityReduce lossSemiconductor/solid-state device detailsTransformers/inductances coils/windings/connectionsCapacitanceEngineering

The present invention provides a differential inductor, at least comprising: a first port, a second port and a bottom coil; the inner and outer metal coils of the bottom coil are connected in a crossing manner through a number of first oblique connecting pieces; the bottom coil A top layer metal coil is formed directly above the outermost metal coil of the coil; the top layer metal coil is connected in parallel with the bottom layer coil through the first port, the second port, and several contacts; the top layer metal coil Only the outermost metal coil is stacked between the coil and the bottom coil and shares all the metal coils in the bottom coil except the outermost metal coil. In the inductor of the present invention, the top-layer coil and the bottom-layer coil are connected in parallel and only the outermost metal coil is stacked, which reduces the coupling capacitance; at the same time, the thickness of the connection is increased, which improves the power-carrying capacity of the coil and reduces loss; the two work together to achieve overall Boost the inductor Q by more than 15%.

Owner:SEMICON MFG INT (SHANGHAI) CORP

Adjustable on-chip inductor with superhigh Q value

ActiveCN103001566BImprove stabilityImprove frequency selection characteristicsTransformersConversion without intermediate conversion to dcCapacitanceControl signal

An adjustable on-chip inductor with a superhigh Q value comprises an inductor unit, a capacitance regulating and controlling unit and a negative resistance regulating and controlling unit. The inductor unit is provided with a primary inductor and a secondary inductor with electromagnetically coupled, and two ends of the primary inductor are connected with radio frequency output. The capacitance regulating and controlling unit is provided with two serially connected variable capacitors C1 and C2, the serial connection ends of the variable capacitors C1 and C2 are connected with an external control signal VC1, and the other ends of the variable capacitors C1 and C2 are respectively connected with an in-phase end and an inverse-phase end of the secondary inductor. The negative resistance regulating and controlling unit is provided with five transistors, a grid electrode of the transistor M1 is connected with an externally input control signal VC2, a source electrode of the transistor M1 is earthed, a drain electrode of the transistor M1 is connected together with source electrodes of the transistors M2 and M3, a grid electrode of the transistor M2 is connected together with drain electrodes of the transistors M3 and M5 and a grid electrode of the transistor M4 and the inverse-phase end of the secondary inductor, a grid electrode of the transistor M3 is connected together with drain electrodes of the transistors M2 and M4 and a grid electrode of the transistor M5 and the in-phase end of the secondary inductor, and source electrodes of the transistors M4 and M5 are connected with a power source VDD (voltage drain drain).

Owner:NANJING QINHENG MICROELECTRONICS CO LTD

A manufacturing method and structure of a miniaturized three-dimensional inductor with a magnetic core

ActiveCN112086282BEasy to integrateSolve the problem of not being able to obtain high inductance densityTransformers/inductances coils/windings/connectionsTransformers/inductances magnetic coresInductor windingsMetallic materials

A manufacturing method and structure of a miniaturized three-dimensional inductor with a magnetic core, comprising the following steps: 1) making at least one microgroove structure on a magnetic substrate; 2) making a plurality of through holes on a hidden frame substrate, and Fill the metal material in the through hole; 3) Cut the hidden frame substrate to form a number of hidden frames with metal materials, and embed the hidden frame in the micro-groove structure and fix it; 4) On the front and back of the magnetic substrate The first planar interconnection structure and the second planar interconnection structure are manufactured respectively, and the first planar interconnection structure and the second planar interconnection structure are respectively electrically connected with the metal material of the recessive frame to form at least one inductance winding. The invention realizes a miniaturized inductance device with high capacity.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA +1

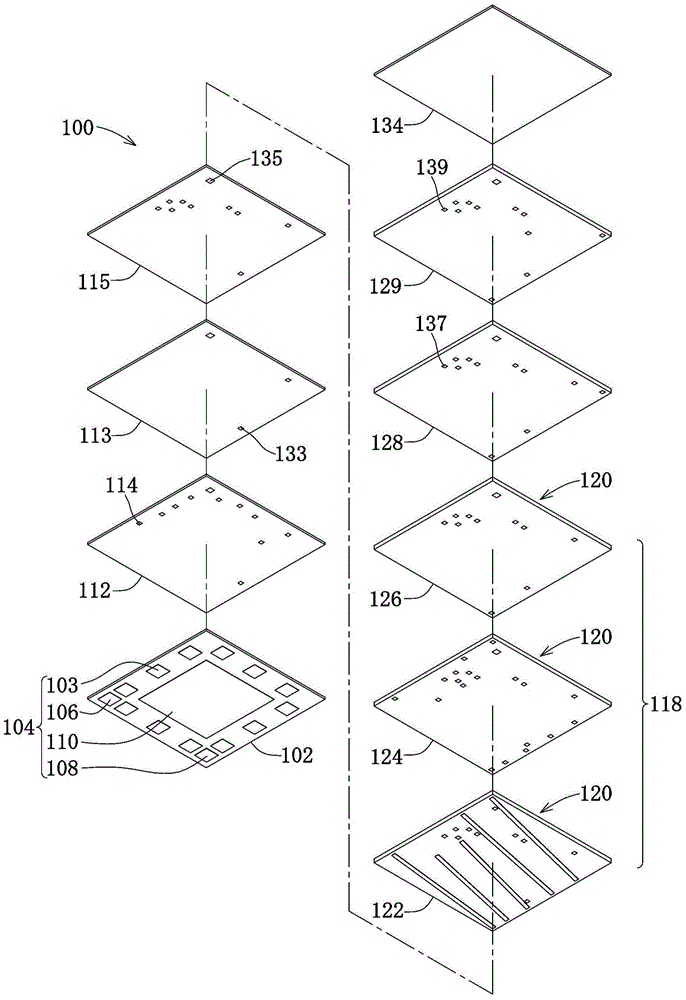

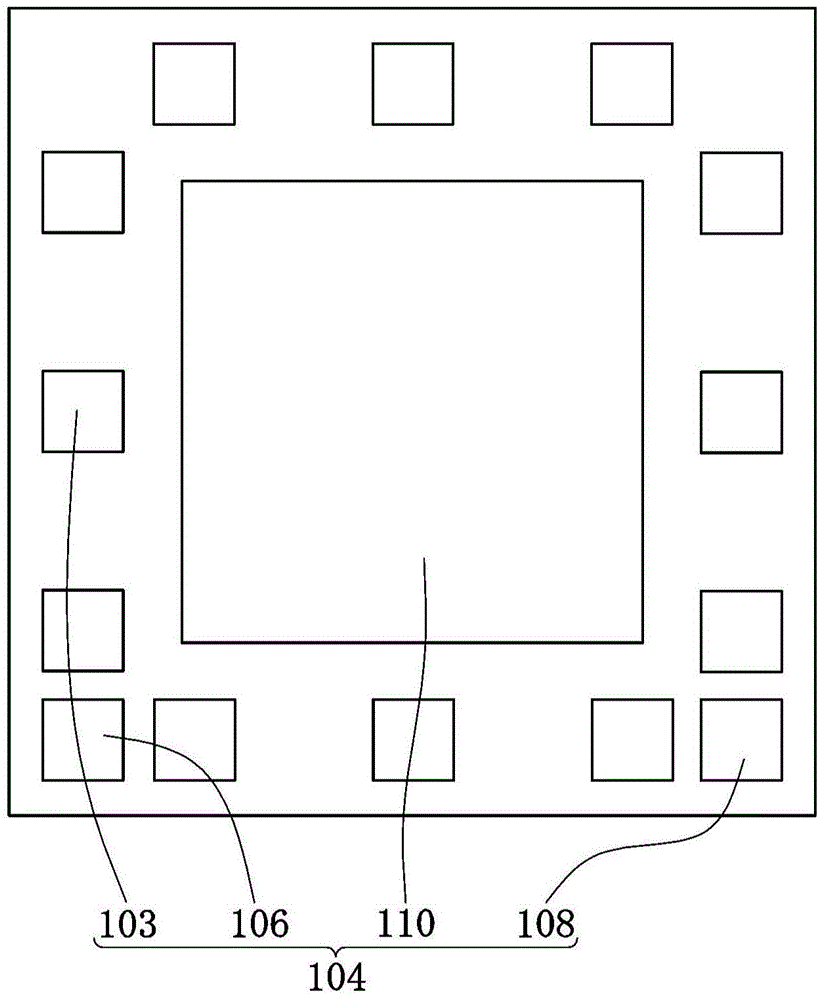

An inductance structure used in printed circuit board embedding technology and its manufacturing method

ActiveCN106332447BMeet the requirements of low-cost manufacturingRaise the sensory valuePrinted inductor incorporationInductorCopper coil

The invention provides an inductance structure used in printed circuit board embedding technology and its manufacturing method, which belongs to the technical field of printed circuit integrated components. The invention improves the structure of the magnetic core and the winding method of the coil to improve the inductance value and the stability of the inductance during use; the inductance structure provided by the invention can reduce the occupied area of the copper coil on the PCB substrate, improve the miniaturization of the size of the inductance element, and make the inductance structure small in size and high in performance; the present invention mainly The inductance structure used in the embedded inductance technology of printed circuit boards is formed by using graphic transfer technology, interlayer through holes, window opening treatment, electroplating and chemical plating, and hot-pressed layering. The manufacturing method is simple and highly controllable. Compatible with the process of the existing printed circuit board technology, it is beneficial to improve the integration degree of printed circuit components.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

inductance

InactiveCN103208347BRaise the sensory valueIt has the effect of magnetic shieldingUnwanted magnetic/electric effect reduction/preventionInductance with magnetic coreInductorElectromagnetic shielding

The invention discloses an inductor, which comprises an outer frame provided with an opening, a magnetic core contained in the outer frame, and a coil wound on the magnetic core. The inductor also comprises magnetic glue, wherein the magnetic glue is sealed on the opening of the outer frame to increase the inductance value of a product and perform the effect of magnetic shielding.

Owner:FOXCONN (KUNSHAN) COMPUTER CONNECTOR CO LTD +1

Inductor, inductor package, conversion circuit and processing method

PendingCN114649309ATo achieve effective layoutRaise the sensory valueSemiconductor/solid-state device detailsSolid-state devicesInductorWire wrap

The embodiment of the invention provides an inductor, an inductor package, a conversion circuit and a processing method. The inductor comprises a first wiring layer provided with at least one section of first wiring; the second wiring layer is provided with at least one section of second wiring; the substrate is arranged between the first wiring layer and the second wiring layer; a first connection end and a second connection end; wherein the at least one section of first wire and the at least one section of second wire penetrate through the substrate and are connected in series to form a winding wire, and the winding wire is arranged between the first connecting end and the second connecting end. In the scheme of the embodiment of the invention, the at least one section of the first wire and the at least one section of the second wire are positioned on different wire layers, so that effective arrangement of the winding wire formed by penetrating through the substrate in series is realized, and the inductance value of the inductor is improved.

Owner:平头哥上海半导体技术有限公司

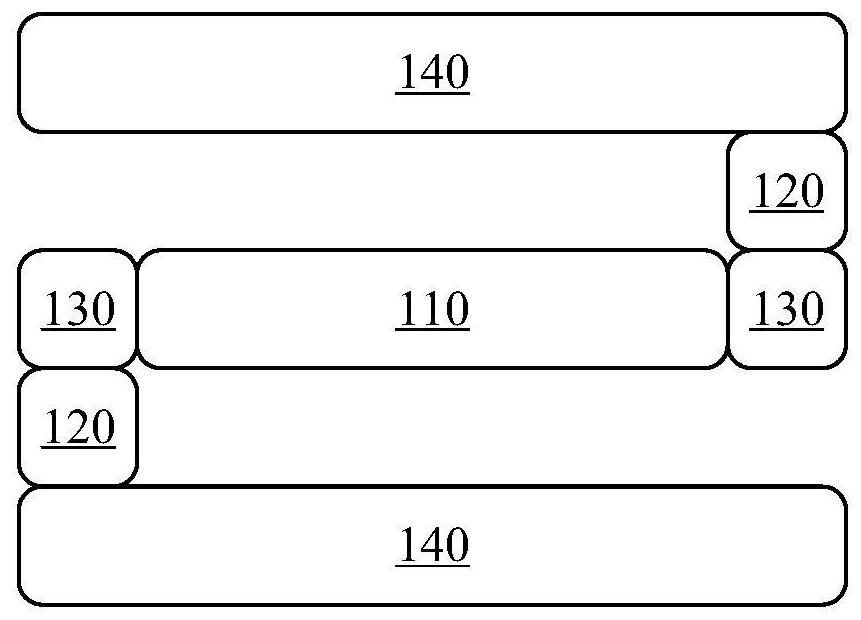

Antenna structure for communication module and manufacturing method thereof

ActiveCN106299633BRaise the sensory valueSimple processLoop antennas with ferromagnetic coreRadiating elements structural formsElectrical conductorEngineering

The invention relates to an antenna structure for a communication module and a fabrication method thereof. The antenna structure comprises a first magnetic substance layer, a second magnetic substance layer, a third magnetic substance layer, a fourth magnetic substance layer, a fifth magnetic substance layer, a sixth magnetic substance layer and a seventh magnetic substance layer which are sequentially arranged, wherein the third magnetic substance layer, the fourth magnetic substance layer and the fifth magnetic substance layer are internally provided a coil-shaped conductor pattern so as to form a magnetic core structure; the first magnetic substance layer is provided with a plurality of bonding pad electrodes, the seventh magnetic substance layer is provided with a plurality of second bonding pad electrodes, the first bonding pad electrodes comprise a first feed-in bonding pad electrode, a second feed-in bonding pad electrode and a plurality of dummy bonding pad electrodes; the third magnetic substance layer, the fourth magnetic substance layer and the fifth magnetic substance layer all have first magnetic permeability, the first magnetic substance layer, the second magnetic substance layer, the sixth magnetic substance layer and the seventh magnetic substance layer all have second magnetic permeability, and the first magnetic permeability is greater than or equal to the second magnetic permeability. The antenna structure adopts materials with high magnetic permeability in the magnetic substance layers containing the magnetic core structure, so that an inductance value of a small-size antenna can be improved.

Owner:INPAQ TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com