Molding component and manufacturing method thereof

A manufacturing method and technology of components, applied in inductor/transformer/magnet manufacturing, coil manufacturing, electrical components, etc., can solve the problem of high stress on electrode metallization coating and bare copper, low cost of electronic components, complex inductor manufacturing process, etc. problem, to achieve the effect of improving comprehensive electrical characteristics, simple manufacturing process, improving inductance value and saturation characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0063] like Figure 1A-1E As shown, a sheet frame molded component and its manufacturing method, comprising the following steps:

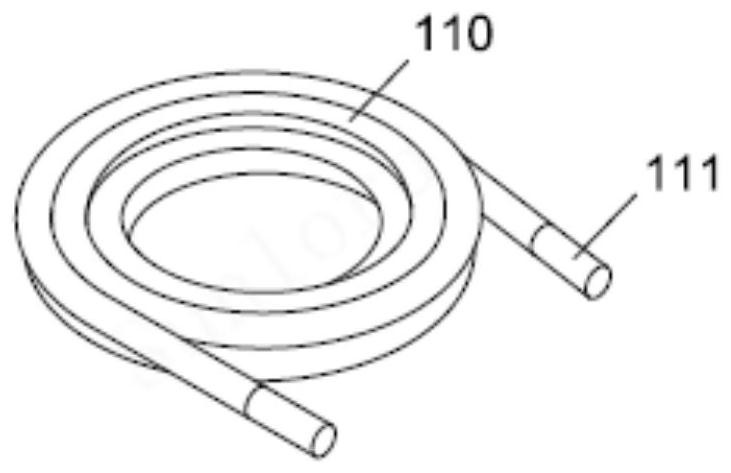

[0064] 1) Making the hollow coil 110

[0065] like Figure 1A , the hollow coil 110 is made of self-adhesive enamelled copper round wire wound in pairs.

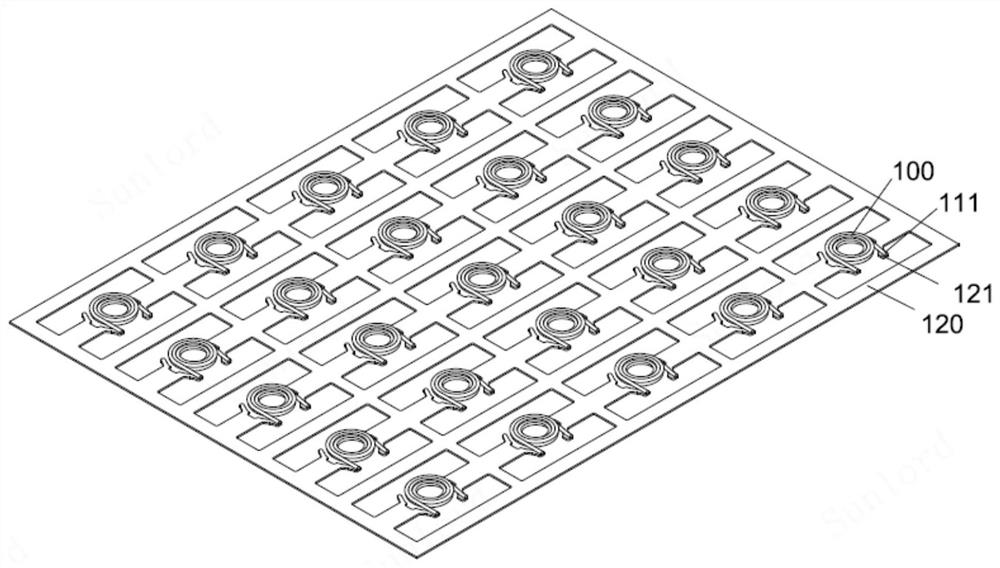

[0066] 2) Spot welding hollow coil and rectangular sheet frame

[0067] Laser spot welding is used to melt the welding corners of the rectangular material frame 120 and the pins 111 of the hollow coil, and the welded assembly after the hollow coil and the material is welded is as follows Figure 1B shown.

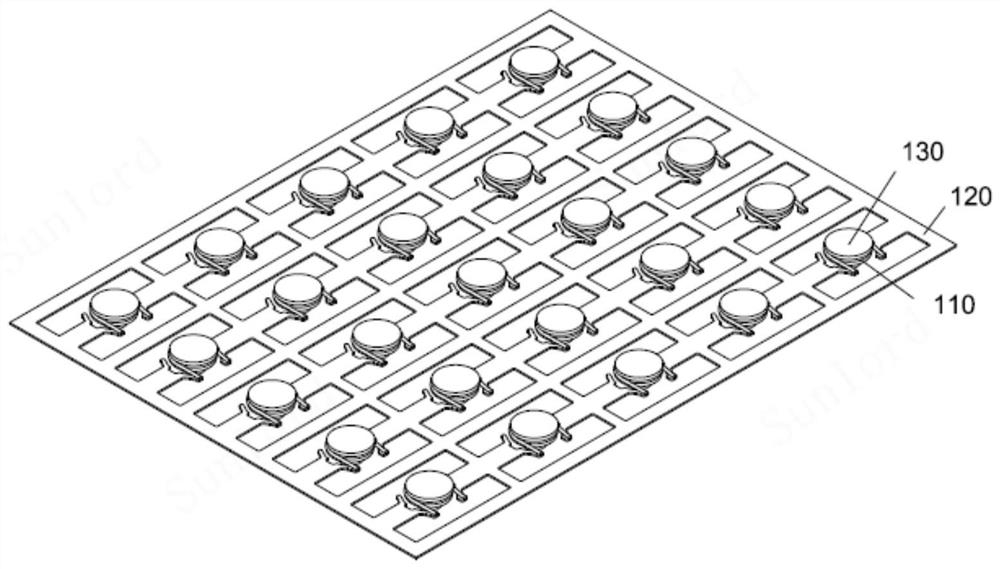

[0068] 3) Implant T-shaped magnetic core

[0069] The T-shaped magnetic core 130 is manufactured by molding and sintering process, and then the central column 131 of the T-shaped magnetic core is implanted into the air-core coil 110. The T-shaped magnetic core is FeSiCr metal soft magnetic powder that has been passivated and insulated. , The magnetic permeability of the magnetic core is p...

Embodiment 2

[0075] like Figure 2A-2E As shown, a material frame type molded inductance bar, its manufacturing method comprises the following steps:

[0076] 1) Make I-shaped magnetic core 210

[0077] like Figure 2A , using molding, cutting and sintering processes to manufacture the I-shaped magnetic core 210, the I-shaped magnetic core is ferrite, the magnetic permeability is preferably 3000-5000, and the saturation magnetic flux is 400-500mT.

[0078] 2) Make air core coil winding

[0079] The flat self-adhesive wires are stacked along the central column of the I-shaped magnetic core 210 to form an air-core coil winding, as shown in 2B, consisting of two parts: the I-shaped magnetic core 210 and the air-core coil 220 .

[0080] 3) The hollow coil winding is welded to the rectangular sheet frame

[0081] Laser spot welding is used to melt the welding corners of the rectangular material frame 230, and cover the pins of the hollow coil 220, and the welded assembly after the hollow co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com