Inductor structure used for printed circuit board embedding technology and manufacturing method thereof

A technology for printed circuit boards and manufacturing methods, which is applied to directions containing printed inductance and printed electrical components, which can solve problems such as instability and low inductance, and achieve increased inductance, reduced occupied area, and improved miniature degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

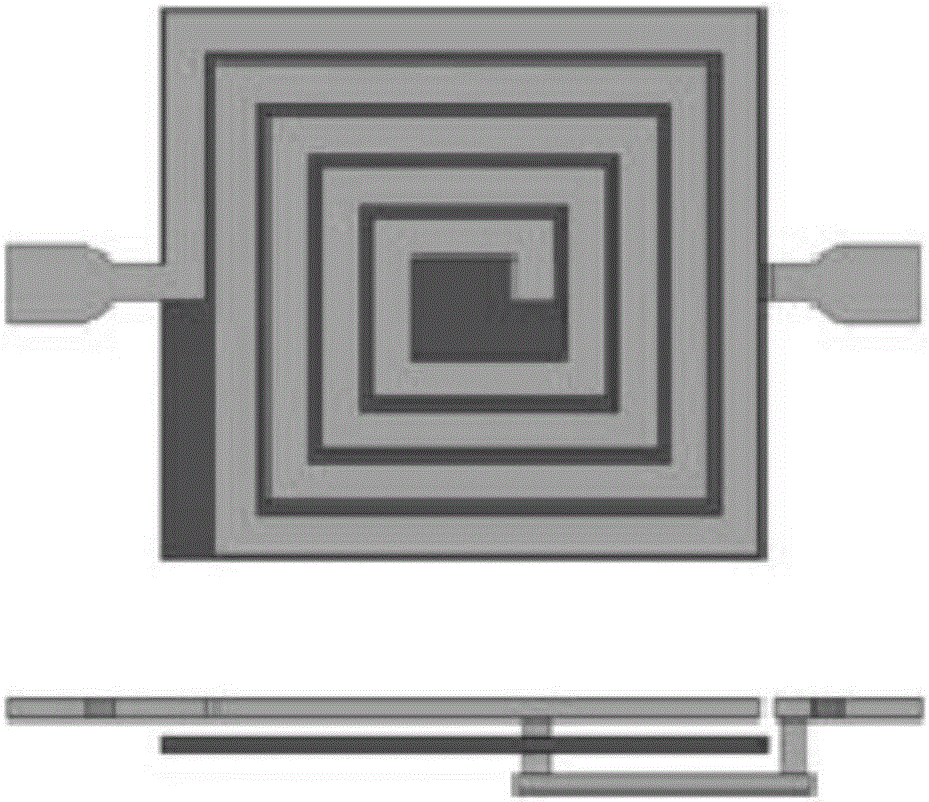

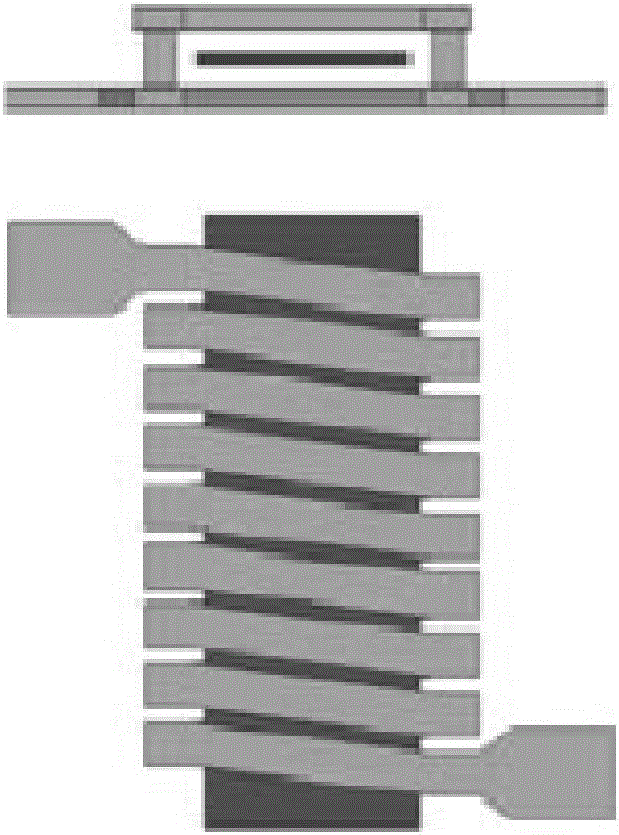

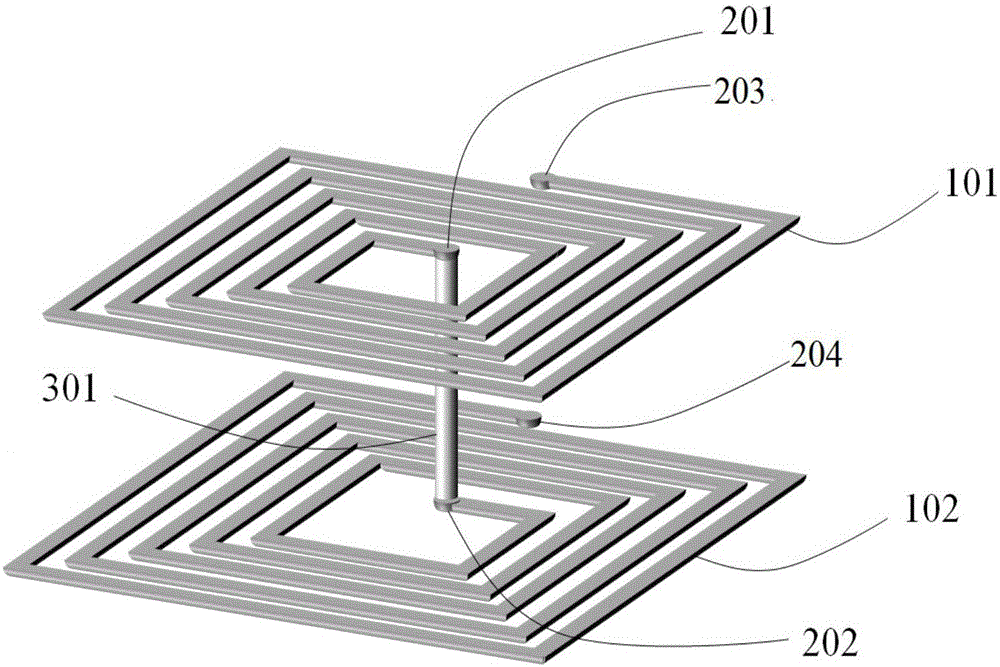

[0044] An inductance structure used in printed circuit board embedding technology, including a first conductive coil 101 and a second conductive coil 102 respectively etched on the top and bottom surfaces of a double-sided copper-clad substrate and a magnetic core located in the two wire coils 7. The inner ends of the first conductive coil 101 coincide with the inner ends of the two conductive coils in the vertical projection formed by the plane where the second conductive coil 102 is located, and the inner ends of the first conductive coil 101 and the inner ends of the second conductive coil 102 A first pad 201 and a second pad 202 are respectively provided, and the first conductive coil 101 and the second conductive coil 102 are arranged between the first pad 201 and the second pad 202 The via hole 301 is connected, and the inner wall of the via hole 301 is coated with a uniform metal layer such as ( image 3 As shown), the non-copper-clad region 1 601 and the non-copper-cla...

Embodiment 2

[0050] A method for manufacturing an inductance structure used in printed circuit board embedding technology, characterized in that it comprises the following steps:

[0051] Step A: After pattern transfer is performed on the top and bottom surfaces of the double-sided copper-clad substrate, the first conductive coil 101 and the second conductive coil 102 are obtained by etching, wherein: the first conductive coil 101 is formed on the plane where the second conductive coil 102 is located In the vertical projection of , the inner ends of the two conductive coils overlap and the single-turn coil in one conductive coil and the single-turn coil in the other conductive coil are arranged alternately from inside to outside to form a tight winding structure;

[0052] Step B: using a numerical control drilling machine to drill a via hole for communication between the first conductive coil 101 and the second conductive coil 102 prepared in step A, and then metallize the inner wall of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com