Inductor bar and manufacturing method thereof

A manufacturing method and inductance technology, which are used in the manufacture of inductors, inductors/transformers/magnets, fixed inductors, etc., can solve the problems of easy sound generation, reduced reliability of electronic circuits, and excessive magnetic leakage of inductors.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

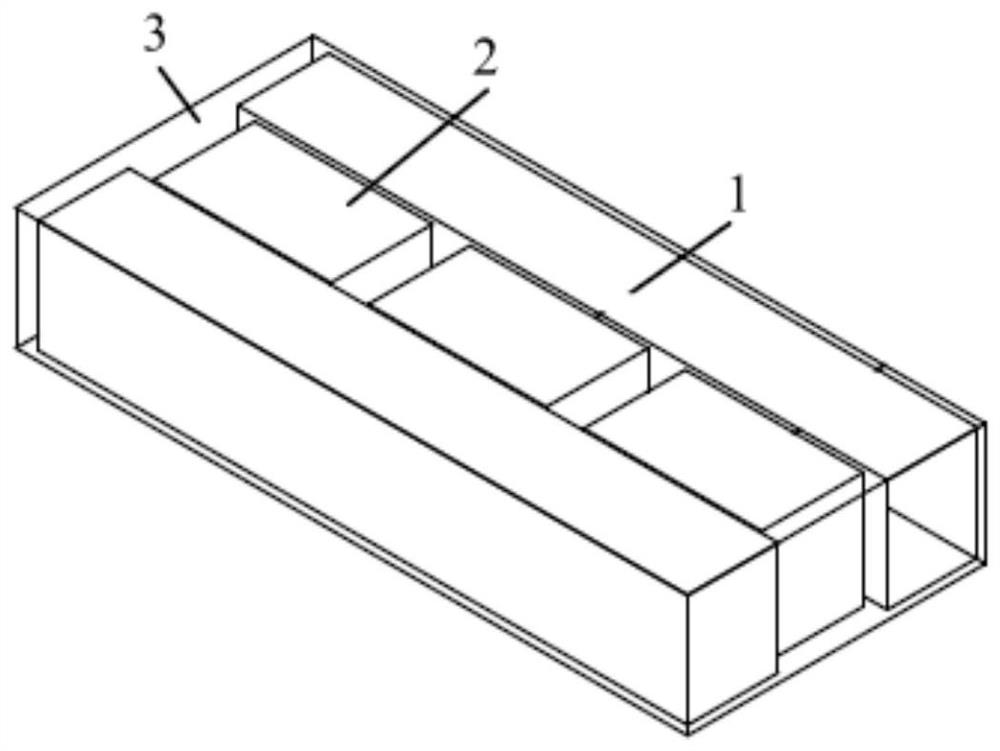

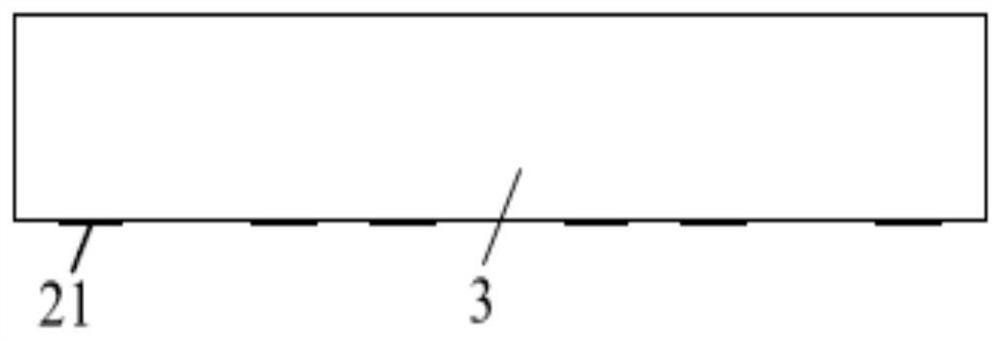

[0040] see Figure 1A and Figure 1B , the present embodiment provides an inductance bar, including: a magnetic core 1, at least two conductors 2 and a magnetic plastic encapsulation layer 3; at least one magnetic core 1; a conductor 2 arranged on the magnetic core 1, and at least two conductors 2 , the conductor 2 includes a surface-insulated base and an electrode portion 21, the conductor 2 is assembled with the magnetic core 1 through the base; the magnetic plastic layer 3 is arranged on the magnetic core 1 and the conductor 2, and the magnetic core 1 and the conductor 2 are located on the magnetic plastic layer 3 Inside, and the magnetic core 1 and the conductor 2 are attached to the magnetic plastic layer 3, and there is no air gap at the joint, and the electrode part 21 of the conductor 2 passes through the magnetic plastic layer 3 to communicate with the outside world.

[0041] The conductor 2 can be a single wire, or a metal terminal, or an air-core coil.

[0042] In th...

Embodiment 2

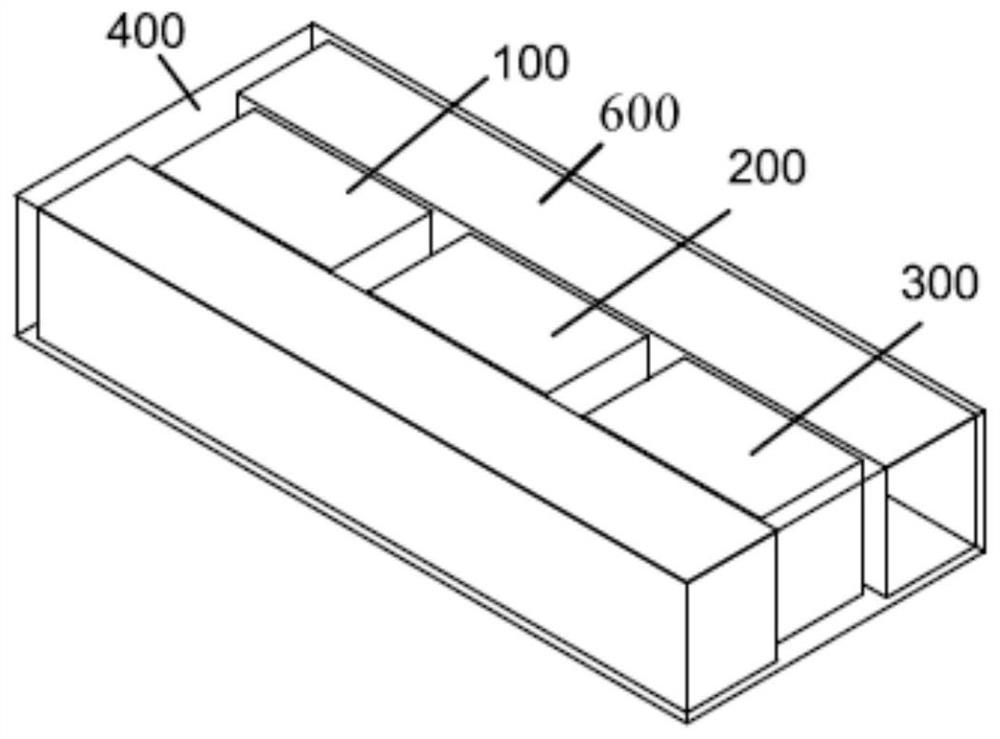

[0048] see Figure 2A , the present embodiment provides an inductance bar, the inductance bar includes: two magnetic cores 600 , three conductors and a magnetic plastic packaging layer 400 .

[0049] In this embodiment, the three conductors are all metal terminals, the three metal terminals are respectively the first metal terminal 100, the second metal terminal 200 and the third metal terminal 300, the first metal terminal 100, the second metal terminal 200 and the The third metal terminals 300 have the same structure.

[0050] see Figure 2B Each metal terminal includes: a base portion 111, a first enclosing portion 112, a second enclosing portion 114, a first electrode portion 113 and a second electrode portion 115, and the terminal is integrally formed; the base portion 111, the first enclosing portion 112, the second The surface of the surrounding part 114 is insulated, and the surface of the first electrode part 113 and the second electrode part 115 are provided with a...

Embodiment 3

[0060] see Figure 3A which is Figure 3C , the present embodiment provides an inductor bar, the inductor bar includes a magnetic core 210 , four conductors and a magnetic plastic packaging layer 500 .

[0061] In this embodiment, the conductor is an air-core coil, and the four conductors are the first air-core coil 100 , the second air-core coil 200 , the third air-core coil 300 and the fourth air-core coil 400 , and the four air-core coils have the same structure.

[0062] see Figure 3B , each air-core coil includes: a base, a first lead-out end 112, a second lead-out end 114, a first electrode portion 113, and a second electrode portion 115; the base is a coil body 111; the first lead-out end 112 and the second lead-out end 114 are respectively disposed on the two electrodes of the coil body 111 ; the first electrode part 113 and the second electrode part 115 are respectively disposed on the first lead-out end 112 and the second lead-out end 114 .

[0063] The surface o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| magnetic permeability | aaaaa | aaaaa |

| magnetic permeability | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com