Laminated sheet type filter and preparation method thereof

A filter and layer-type technology, which is applied in the direction of impedance network, electrical components, multi-terminal pair network, etc., can solve the problems of increasing the size and weight of the filter, reducing the reliability of the filter, and the resonance frequency is not high, so as to alleviate the interface effect , Expand the application range of working frequency, and the effect of small parasitic parameters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

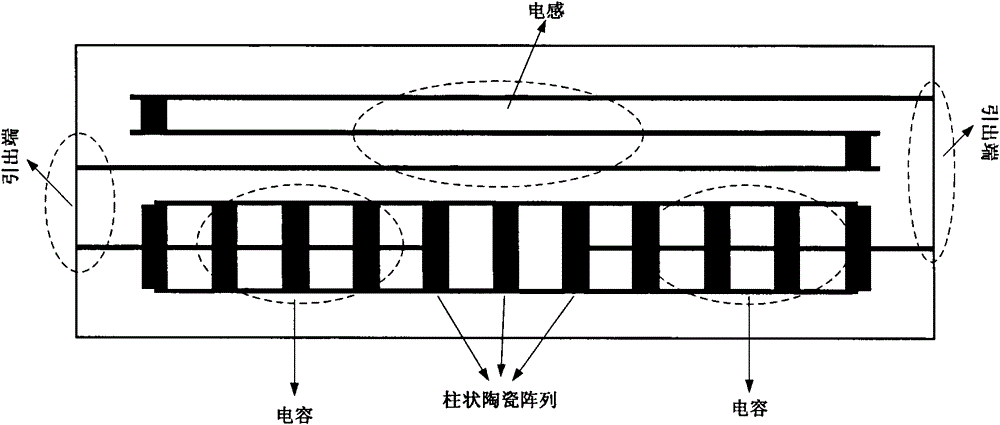

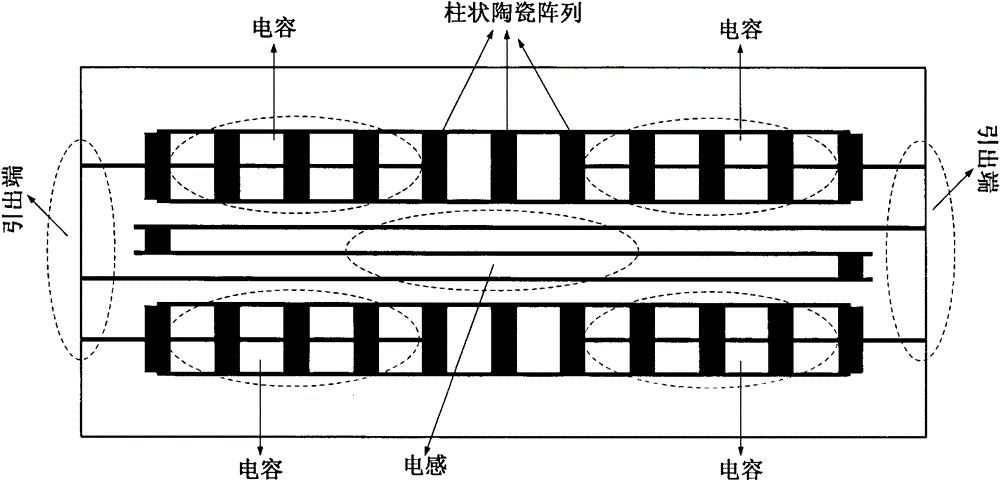

[0017] A multilayer chip filter, such as figure 1 As shown, it is composed of multilayer chip capacitors and multilayer chip core inductors, and has a multilayer chip structure. The multi-layer chip core inductor is formed by stacking and sintering ferrite diaphragms with conductor lines printed on the surface of multiple layers. The conductor lines on the surface of the multi-layer ferrite diaphragms are connected to each other and form an inductance coil. The inductance coil One lead-out end is connected to one end electrode of the whole filter, and the other lead-out end is connected to the other end electrode of the whole filter. The laminated chip capacitor includes two terminal electrode plates and a ground electrode plate, wherein one terminal electrode plate is connected to one terminal electrode of the whole filter, and the other terminal electrode plate is connected to the other terminal electrode of the whole filter, The ground electrode plate is connected to the g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com