Wireless charging coil assembly

A coil assembly, wireless charging technology, applied in the direction of transformer/inductor coil/winding/connection, electrical components, transformer/inductor components, etc., can solve the problems of large impedance, increased transmission loss, small inductance, etc. The effect of improving efficiency, reducing impedance and increasing inductance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

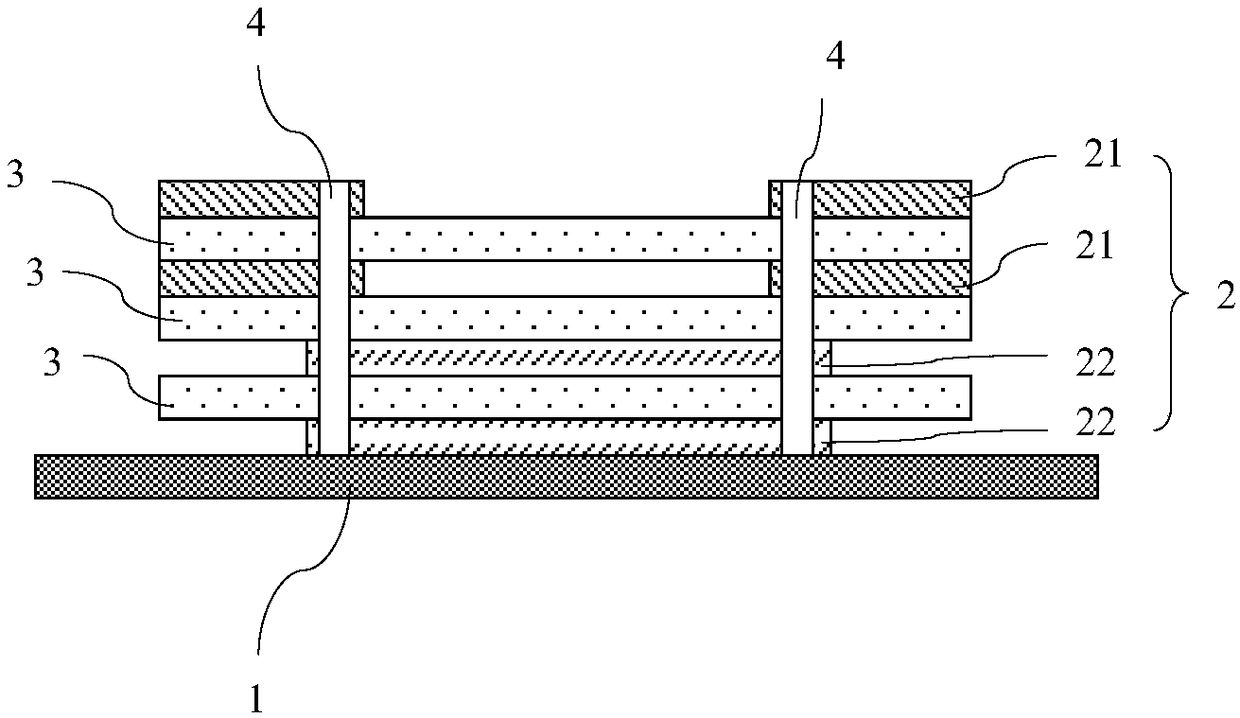

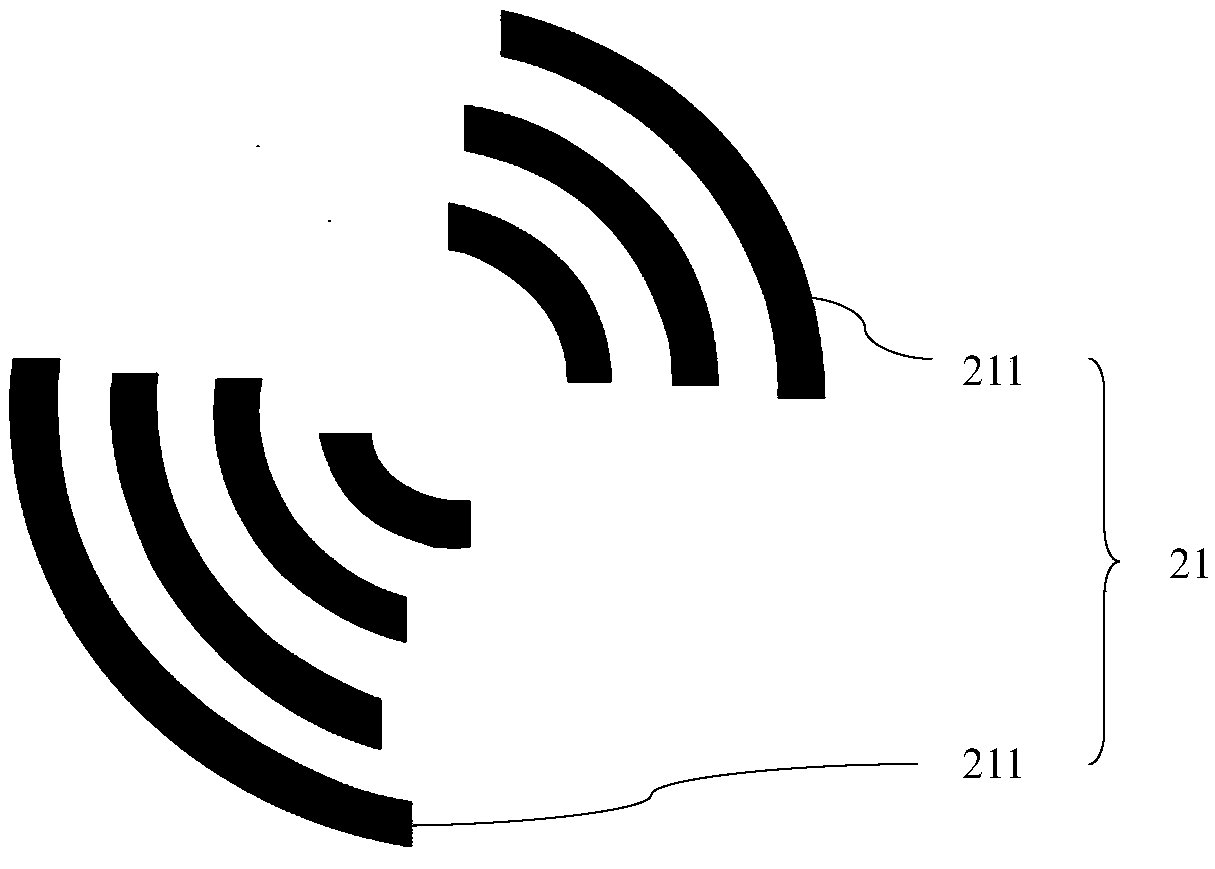

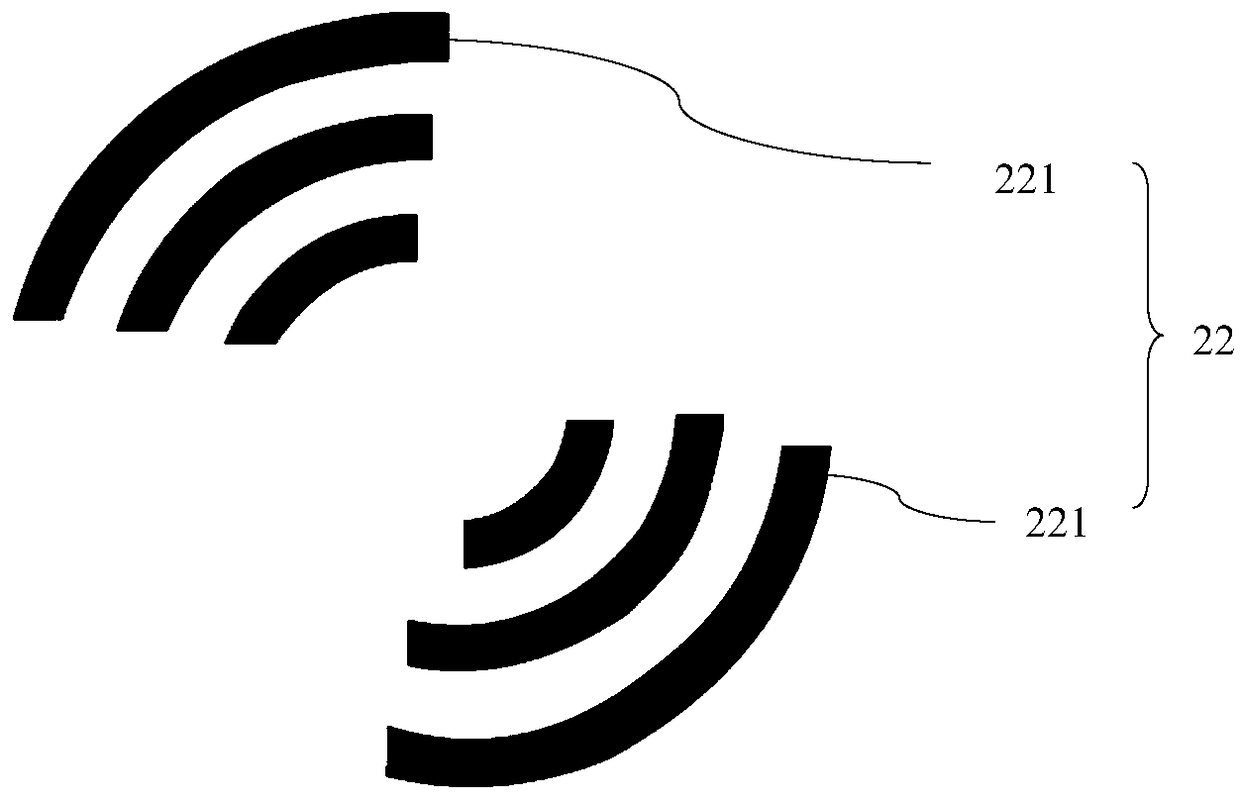

[0018] The structure of the wireless charging coil assembly of the present invention will be further described below in conjunction with the drawings and embodiments:

[0019] It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

[0020] In the design of wireless charging coils, one of the key parameters is the quality factor Q value of the coil, which is directly related to the performance of the entire coil and the transmission loss. The Q value is calculated according to the following formula:

[0021]

[0022] Among them, the smaller the Q value, the lower the transmission efficiency of the coil, which affects the transmitted energy, and most of the energy is lost during the transmission process; the larger the Q value, the better the transmission efficiency of the coil. R is the coil impedance, L is the coil inductance. Based on the guidance of this formula, in the des...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com