Laminated differential inductor with top layer metal and second layer metal of equal thickness

A top-layer metal and differential inductance technology, applied in the field of microelectronics, can solve the problem of large area of inductance, and achieve the effect of improving inductance value, Q value and inductance value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

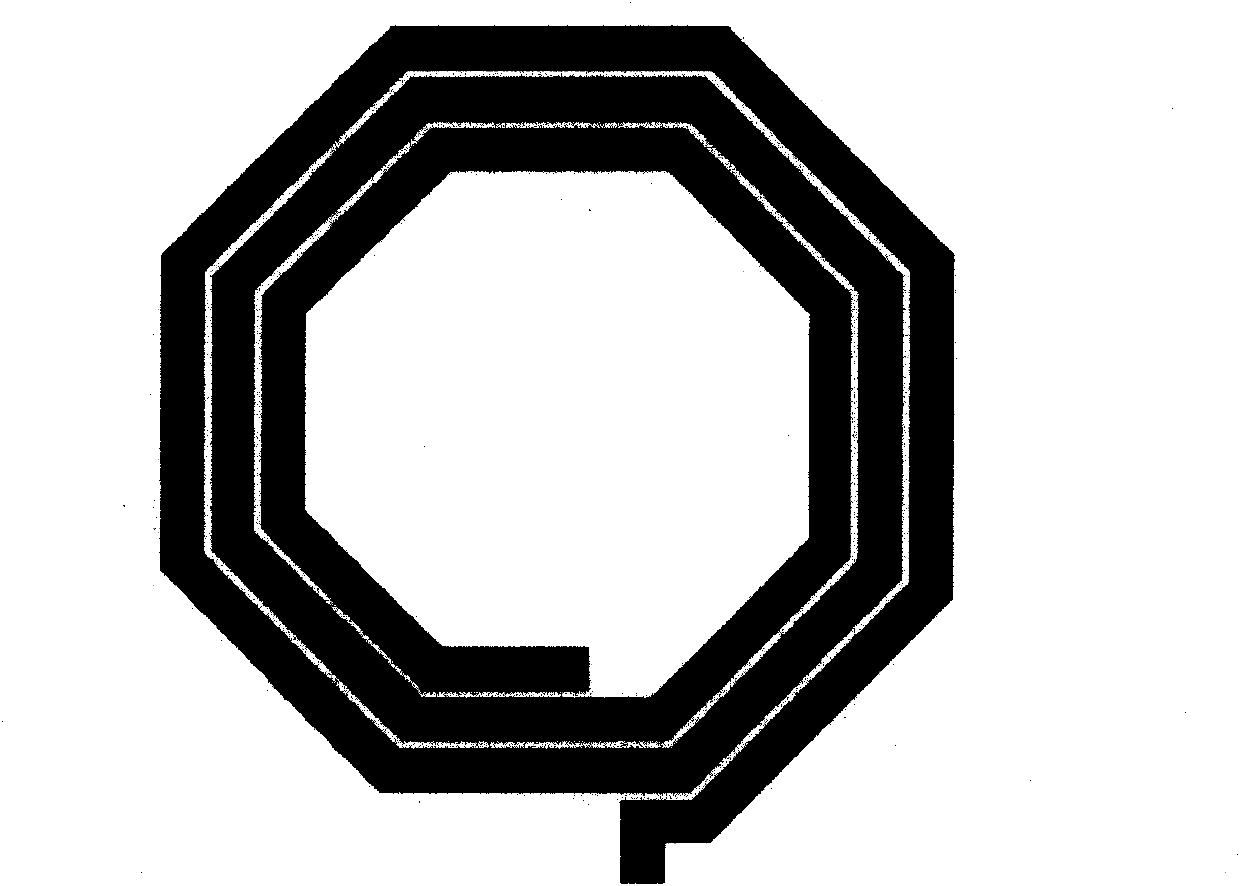

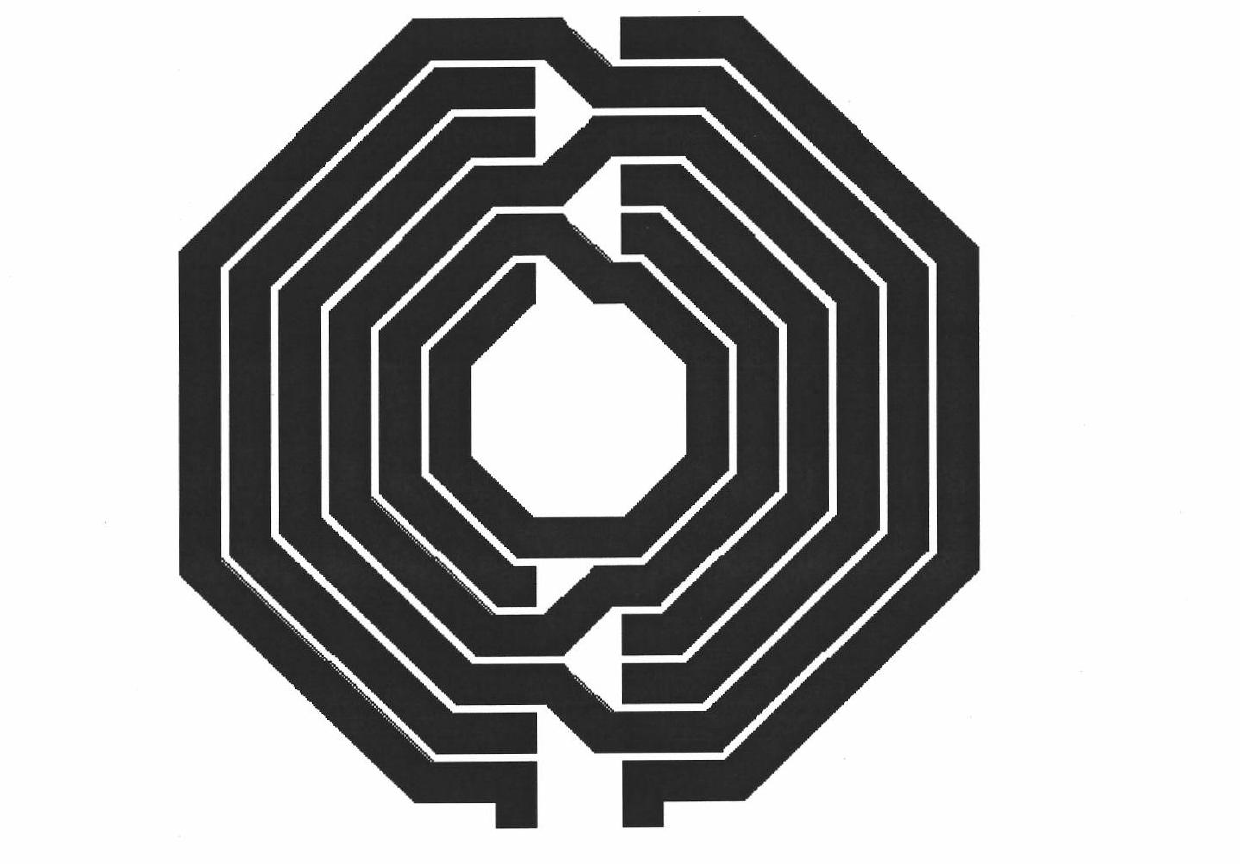

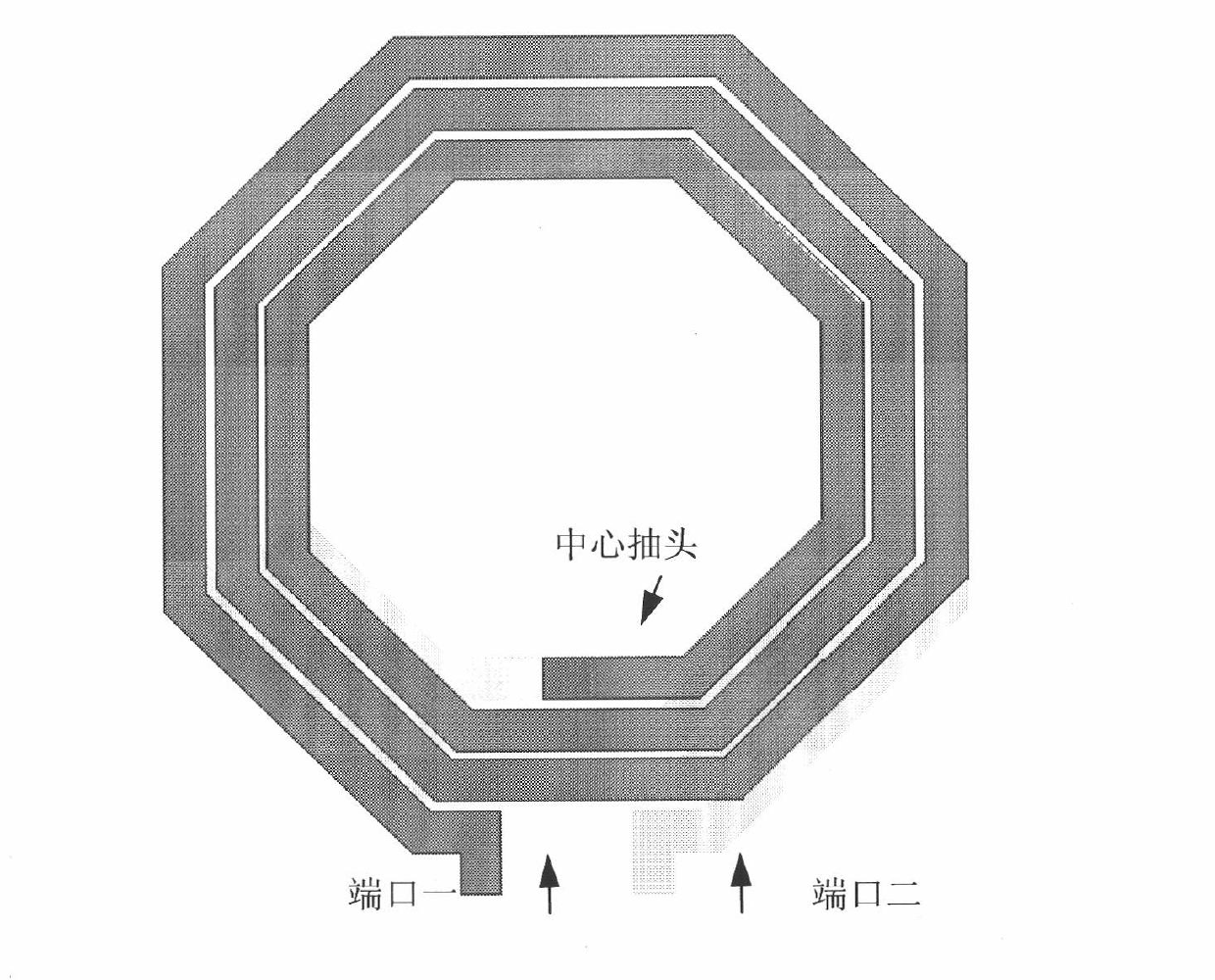

[0016] The stacked differential inductor with the same thickness of the top layer and the second top layer metal of the present invention; it is a multi-layer structure, including: the upper and lower layer metal coils, the upper and lower layer metal coils have symmetrical patterns, and the thickness of the upper and lower layer metal coils is equal; the metal coils There is an inductance port; the inductance starts from one inductance port, spirally winds to the innermost end on the first layer of metal coils, and then connects to another layer of metal coils through interlayer through holes; the other layer of metal coils is screwed again The wire is wound to the outermost end, and the upper and lower layer metal coils are interconnected through interlayer through holes.

[0017] In more detail, the stacked differential inductance planar structure with the same thickness of the top layer and the second top layer metal described in the present invention (take two layers of me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com