Inorganic adhesive for aluminum paste of silicon solar cells and preparation method thereof

A technology for silicon solar cells and inorganic adhesives, applied in the directions of inorganic adhesives, adhesives, circuits, etc., can solve the problems of large bending, low cohesion, and high sintering temperature of the battery sheet, reduce surface tension, and process methods. Simple, increased wetting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

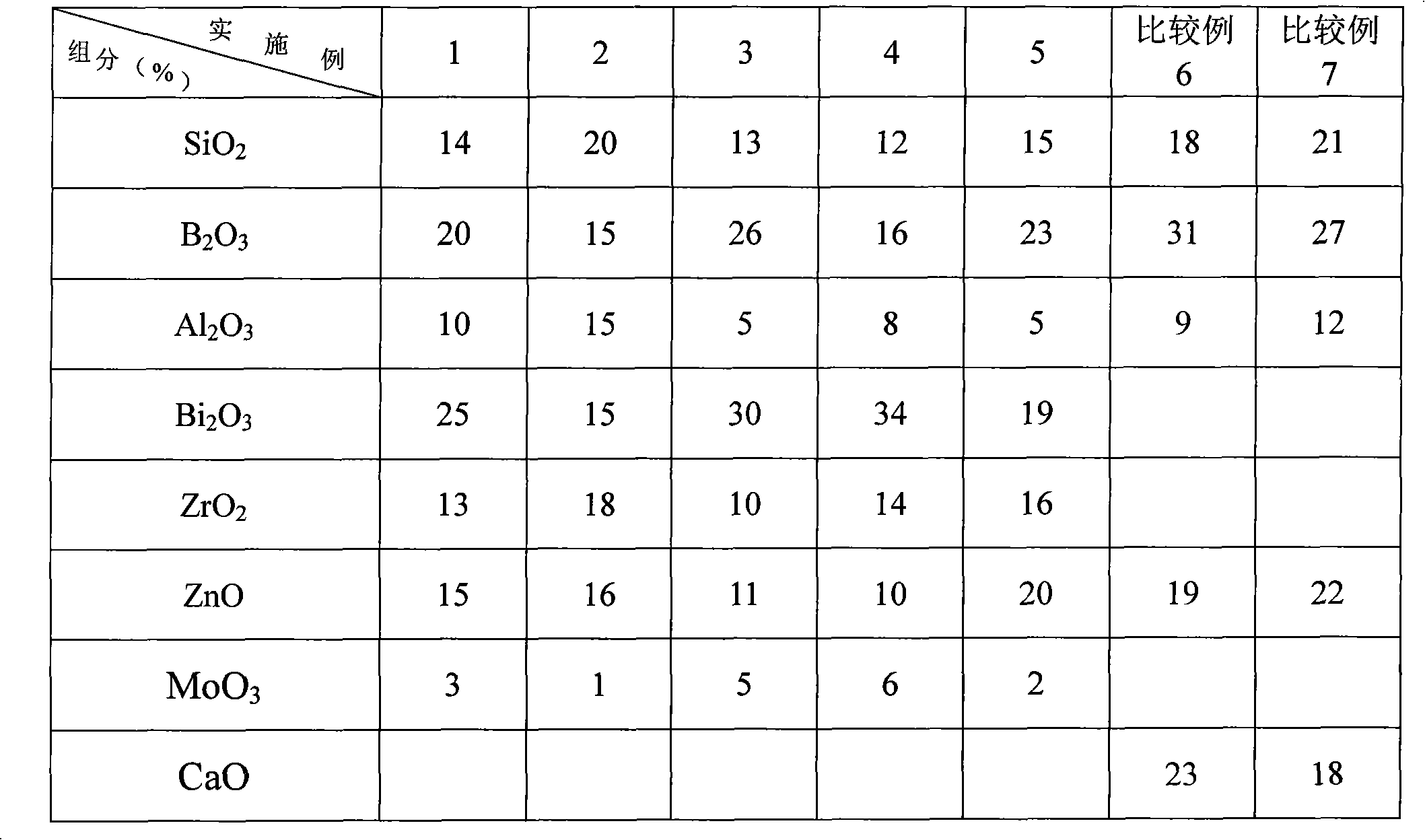

[0031] The composition of the inorganic binder is: by mass parts SiO 2 14%, B 2 o 3 20%, Al 2 o 3 10%, Bi 2 o 3 25%, ZrO 2 13%, ZnO 15%, MoO 3 3%, the above-mentioned composition is as shown in Example 1 in Table 1, and the components in Table 1 are mass percentages.

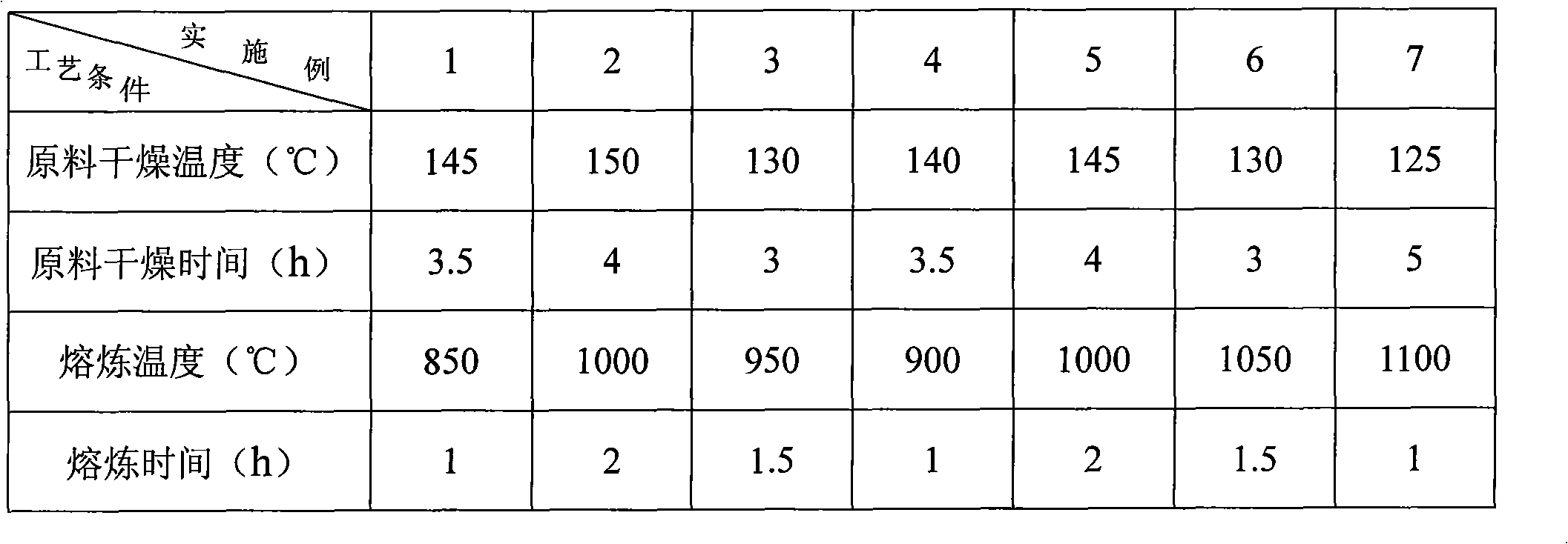

[0032] Inorganic binder preparation steps: Put the above components into a mixer and mix them evenly, put them into a porcelain crucible, dry them in an oven at 145°C for 3.5 hours, put them in a high-temperature furnace, melt them at 850°C for 1 hour, and then dry them after water quenching Dry, use a planetary ball mill to mill to a size below 10 μm, and dry to obtain the finished inorganic adhesive for aluminum paste for silicon solar cells. The above-mentioned preparation process conditions are shown in Example 1 in Table 2.

[0033] Inorganic binder performance test:

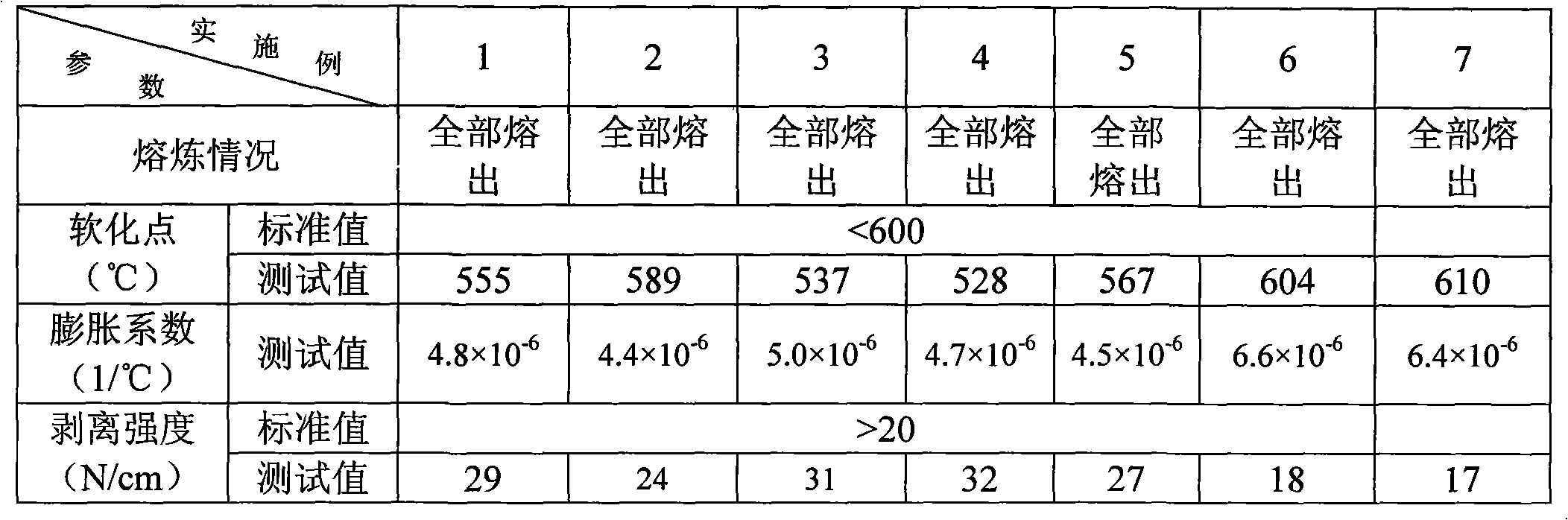

[0034] According to ASTM C338-199 standard, the softening point is 555°C with SP1000 glass softening point tester, and the ex...

Embodiment 2- Embodiment 5

[0047] The component amounts of the inorganic binder, the preparation steps and the test results related to the performance indicators of the inorganic binder of the present invention are shown in Table 1, Table 2 and Table 3 respectively, and the description of the rest of the process is the same as that of Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Softening point | aaaaa | aaaaa |

| Coefficient of expansion | aaaaa | aaaaa |

| Peel strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com