High-temperature resistant workshop primer and preparation process thereof

A technology of shop primer and high temperature resistance, applied in anti-corrosion coatings, coatings, etc., can solve the problems of serious carbonization of the coating, loss of anti-rust function, increase of workload, etc., to reduce atomization, reduce workload, and improve resistance. The effect of high temperature performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

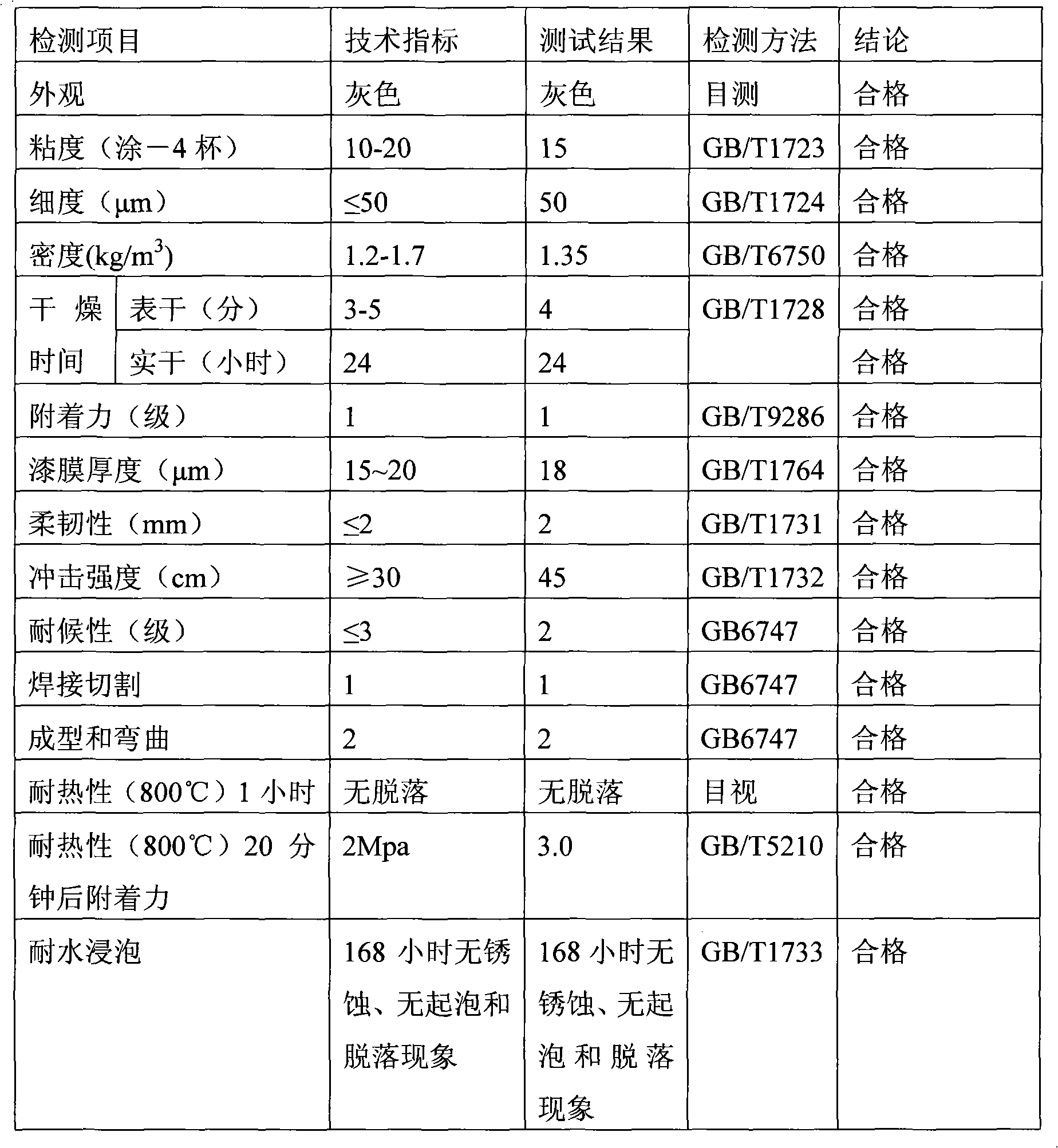

Image

Examples

Embodiment Construction

[0048] The following examples further describe the present invention:

[0049] Case 1:

[0050] Composition ratio of curing agent

[0051] Ethyl orthosilicate (E-40) 34.5 kg

[0052] Isopropanol 50.5 kg

[0053] 3 kg distilled water

[0054] Industrial ethanol 4 kg

[0055] Sulfuric acid 0.12 kg

[0056] Potassium fluoride 0.78 kg

[0057] Potassium hydroxide 0.1 kg

[0058] Sodium ethoxide 2 kg

[0059] Silicone 5 kg

[0060] Preparation Process:

[0061] First, 2 kg of sodium ethylate solution and 15.15 kg of isopropanol were made into 17.15 kg of mixed solution A for subsequent use. Heat the temperature of the normal-pressure reactor to 50±2°C, gradually add: 35.35 kg of isopropanol, 34.5 kg of tetraethyl orthosilicate, 2 kg of industrial ethanol, stir evenly, then dropwise add 2 kg of industrial ethanol and 3 kg of water , 0.12 kilograms of 75% sulfuric acid, the mixed solution of 0.78 gram potassium fluoride, after reacting for 100 minutes, add 5 kilograms of sil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com