Single-component fluorine-carbon-aluminum powder baking varnish, preparation, special thinning agent and use method thereof

A single-component, diluent-based technology, applied in coatings, etc., can solve problems such as high energy consumption, high production costs, and gaps in weather resistance, and achieve excellent pollution resistance, beautiful coating appearance, and reduced energy consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0063] Preparation of fluorocarbon silver powder baking varnish main paint of the present invention:

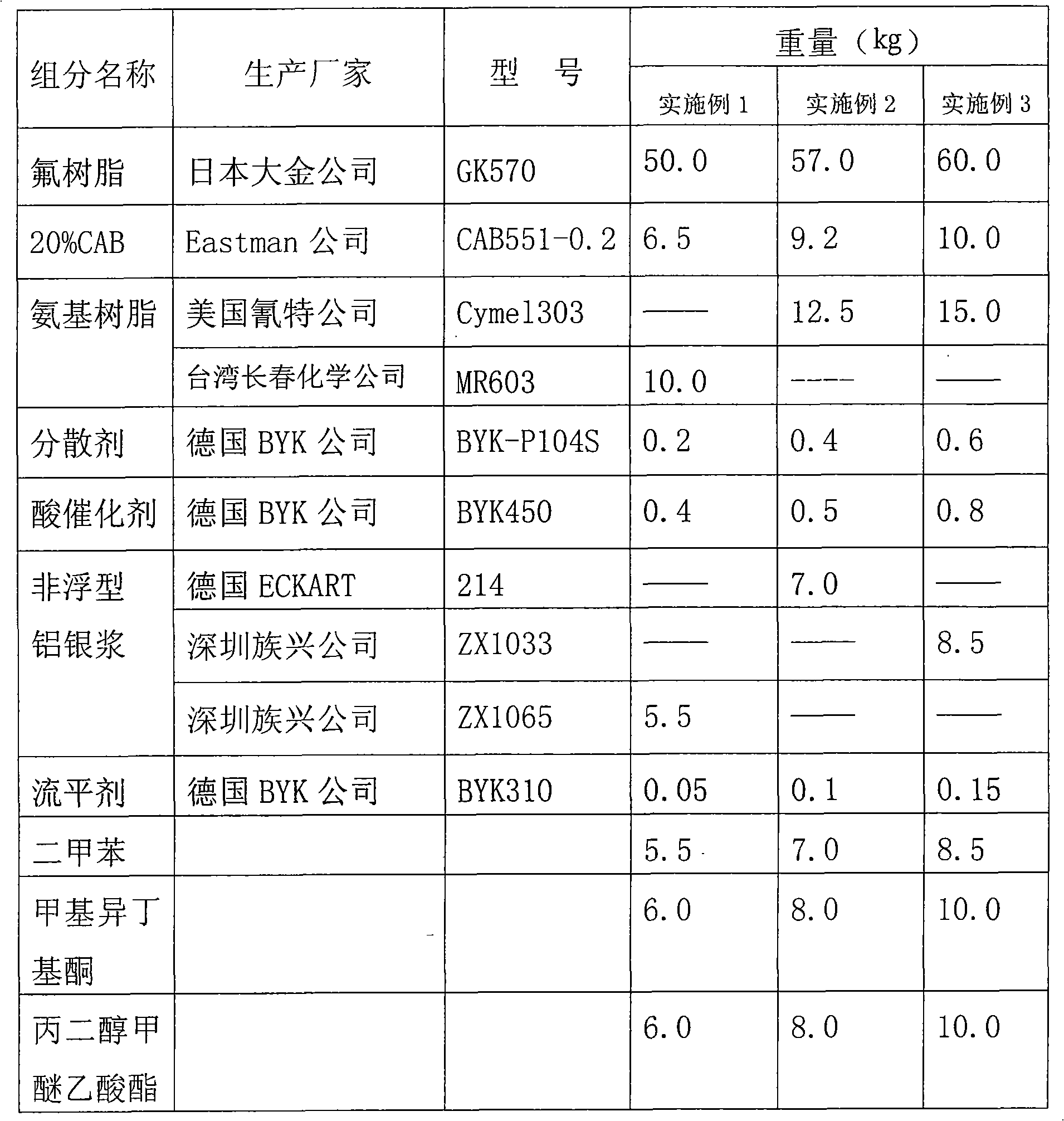

[0064] Get each component according to the weight listed in "Example 1" listed in Table 1, and the preparation method is as follows:

[0065] Step 1. Pre-dispersion of aluminum-silver paste: Mix aluminum-silver paste and an equal amount of xylene, stir at a low speed until there are no aggregated aluminum powder particles, and set aside;

[0066] Step 2. Take the fluororesin, 20% CAB551-0.2, and amino resin in the components according to the weight ratio, stir and mix evenly at a low to medium speed, then add the dispersant, stir at a medium speed for 5-10 minutes, and then add in parts by weight Leveling agent, methyl isobutyl ketone, propylene glycol methyl ether acetate, acid catalyst, mix well at low to medium speed.

[0067] Step 3. Add the aluminum silver paste pre-dispersed in the above step 1 to the paint obtained in step 2 under low-speed stirring, continue stirring...

Embodiment 2

[0076] With each component weight of " embodiment 2 " listed in table 1, repeat the method described in embodiment 1 (only each component weight changes), prepare fluorocarbon silver powder stoving varnish master paint; Repeat diluent in embodiment 1 The components, proportioning and preparation method were used to prepare the diluent; the main paint and the diluent were mixed uniformly according to 1:0.6, and then the construction and drying were carried out according to the method described in Example 1 to obtain the fluorocarbon silver powder baking paint film. The test results (dry film thickness is the same as in Example 1) are shown in the corresponding data of "Example 2" in Table 2.

Embodiment 3

[0078] With each component weight of " embodiment 3 " listed in table 1, repeat the method described in embodiment 1 (only each component weight changes), prepare fluorocarbon silver powder stoving varnish master paint; Repeat diluent in embodiment 1 The components, proportioning and preparation method were used to prepare the diluent; the main paint and the diluent were mixed evenly according to 10.5, and then the method described in Example 1 was applied and dried to obtain a fluorocarbon silver powder baking paint film, and the routine performance test results (Dry film thickness is the same as embodiment 1) as shown in the corresponding data of " embodiment 3 " in table two.

[0079] Table II

[0080] serial number

[0081] Note: In Table 2, when doing the artificial weathering resistance test, the surface of the paint film should be covered with the same kind of varnish.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Flexibility | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com