Elastic fluorocarbon silver paint and preparation method thereof and use method

A silver powder paint, elastic technology, used in metal-free paints, polyurea/polyurethane coatings, devices for coating liquids, etc., to achieve excellent decorative properties, excellent stain and scrub resistance, excellent weather resistance sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

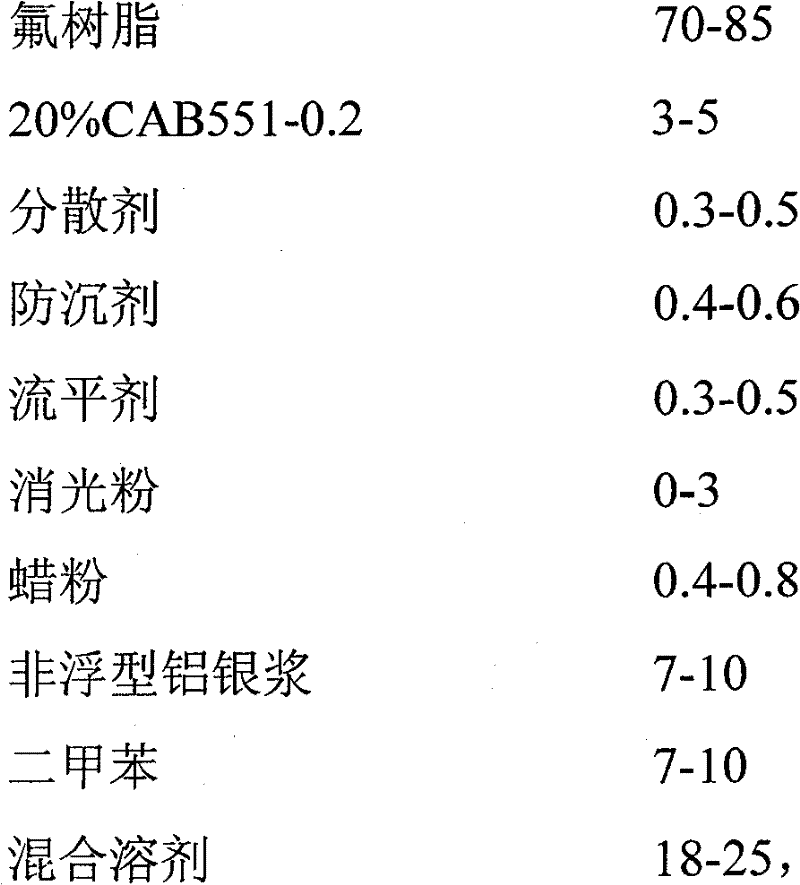

[0053] Prepare fluorocarbon silver powder paint main paint of the present invention:

[0054] According to the weight shown in Example 1 in Table 1, each component is taken, and the preparation method is as follows:

[0055] Step 1: Pre-dispersion of aluminum-silver paste: Mix the aluminum-silver paste in the formula with an equal amount of xylene, stir at a low speed until there are no aggregated aluminum powder particles, and set aside;

[0056] Step 2: Take the fluororesin and 20% CAB551-0.2 in the components according to the weight ratio in the formula, stir and mix evenly at low to medium speed, then add dispersant, stir at medium speed for 5 minutes, and then add anti-settling agent by weight After adding, disperse at high speed for 5-10 minutes to a fineness of ≤25 μm, then add wax powder under low-speed stirring, disperse at high speed for 15 minutes after adding, then add leveling agent and mixed solvent and stir at low to medium speed to mix evenly;

[0057] Step 3:...

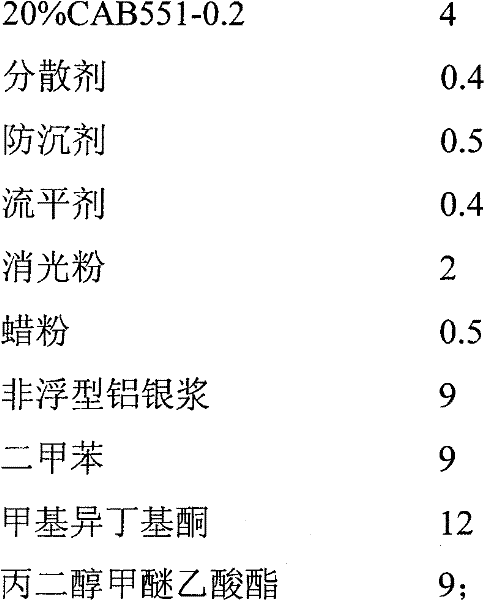

Embodiment 2

[0066] According to the parts by weight of each component in Example 2, repeat the method described in Example 1, wherein the matting powder and wax powder are added together to prepare the elastic fluorocarbon paint main paint, curing agent and thinner. According to the main paint: curing agent: diluent = 125.9: 25.8: 75 (among them, the main paint and curing agent are mixed according to the ratio of OH / NCO = 1: 1.1) and then sprayed, and the fluorocarbon silver powder can be obtained after spraying and drying naturally Paint film, dry at room temperature for 24 hours, completely dry for 7 days. The performance testing results (the thickness of the dry coating film when testing the elongation rate is (1±0.2) mm, and the rest are in accordance with relevant standards) are shown in the corresponding data of Example 2 in Table 2.

Embodiment 3

[0068] According to the weight of each component in Example 3, the method described in Example 1 was repeated, wherein the matting powder and wax powder were added together to prepare the elastic fluorocarbon paint main paint, curing agent and thinner. According to the main paint: curing agent: thinner = 140.6: 35.8: 95 (among them, the main paint and curing agent are mixed according to the ratio of OH / NCO = 1: 1.15) and then sprayed, and the fluorocarbon silver powder can be obtained after spraying and drying naturally Paint film, dry at room temperature for 24 hours, completely dry for 7 days. The performance testing results (thickness of the dry coating film when testing the elongation rate is (1±0.2) mm, and the rest are in accordance with relevant standards) are shown in the corresponding data of Example 3 in Table 2.

[0069] Table II

[0070]

[0071]

[0072] Note: The test of weather resistance, acid resistance and mortar resistance should be finished with the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com