Preparation method of inorganic-organic double-layer coated type aluminum paste

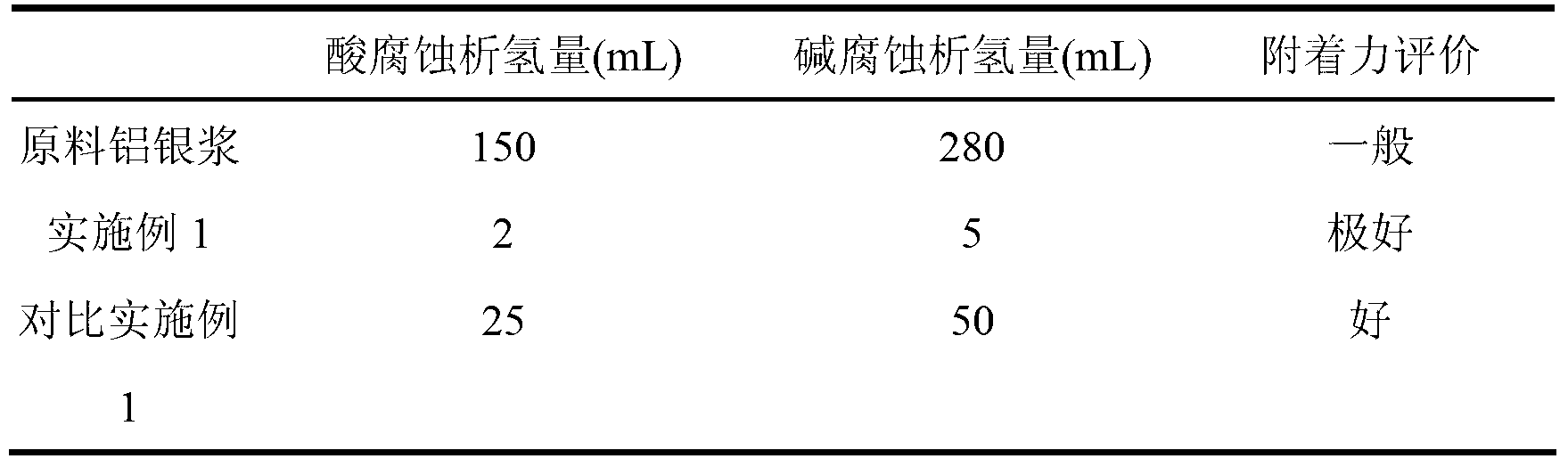

An aluminum-silver paste and aluminum-coated technology, which is applied in the treatment of dyed organosilicon compounds, dyed polymer organic compounds, coatings, etc. The problem is to achieve excellent acid and alkali corrosion resistance, maintain hiding power, and improve acid and alkali corrosion resistance and adhesion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

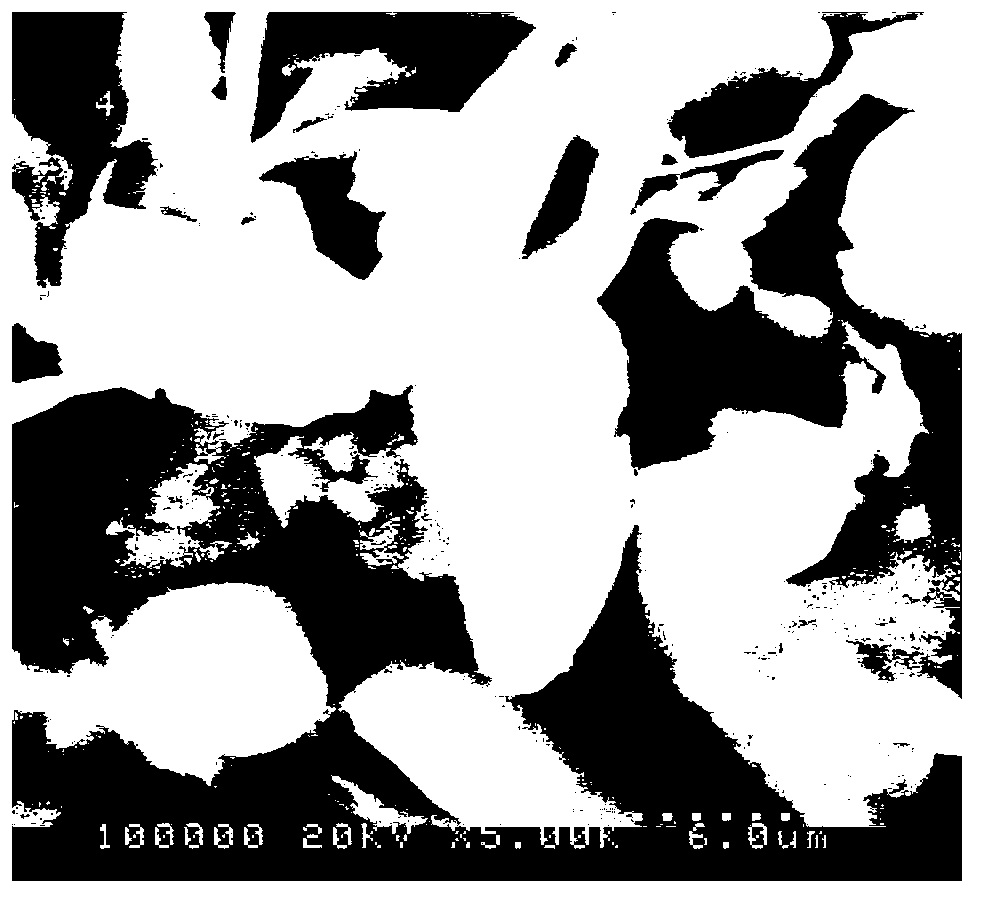

Image

Examples

Embodiment 1

[0032] Weigh 20g of aluminum silver paste with a solid content of 50-70% and add it to a mixture of 100mL isopropanol and 50mL water, stir and heat and control the temperature of the whole system at 60-70°C, under the catalytic action of 2.0mL ethylenediamine , drop 10g tetraethyl orthosilicate in 1 hour; after dropping, continue to react for 5 hours, cool, wash, and filter to obtain inorganic silica-coated aluminum-silver paste; Add 10g of inorganic silica-coated aluminum silver paste and 100mL of toluene to a 250mL round bottom flask with a funnel and a reflux condenser, and stir thoroughly for about 30 minutes; add 0.2g of methacryloxypropyltrimethoxysilane, and stir for 30 minutes; then add 10 mL of toluene solution dissolved with 0.2 g of azobisisobutyronitrile, and stir for 30 minutes; vacuumize the system and ventilate nitrogen, repeat three times, and keep a continuous nitrogen atmosphere protection throughout the reaction process; place the flask in Heat to 70°C in a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com