Process for forming vibration and extrusion process prestressed concrete pipe through core mold vibration method

A concrete pipe and prestressing technology, which is applied in the technological field of forming a one-stage prestressed concrete pipe by using the core mold vibration method, can solve the problems of increased residual water content, low concrete compactness, and increased ovality of the pipe. Improve the vibration frequency and vibration intensity, overcome the effects of low concrete density and uniform vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Such as figure 1 , 3 Shown: The process of forming a one-stage prestressed concrete pipe using the mandrel vibration method is carried out in accordance with the following steps:

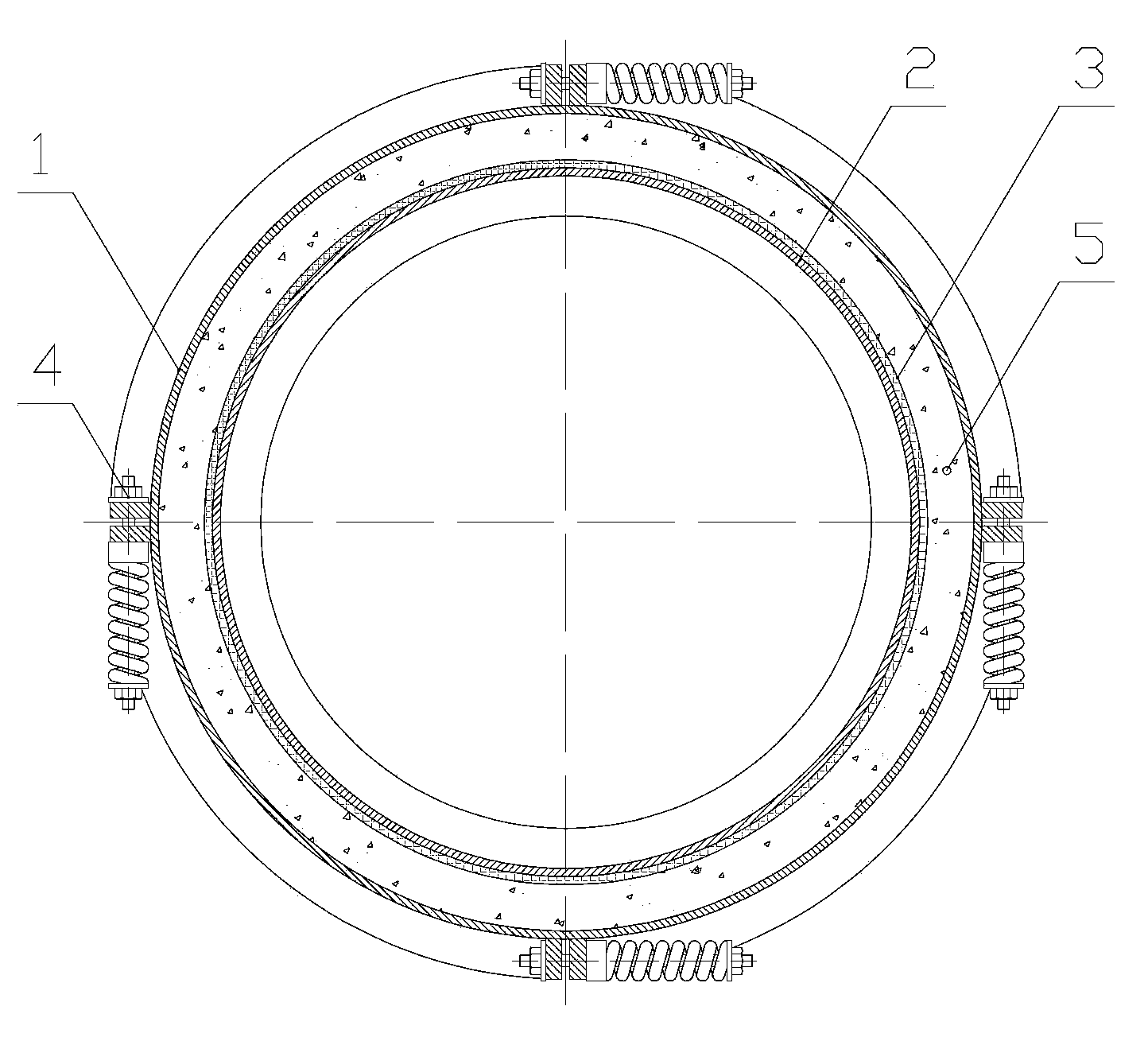

[0032] a. Model assembly: The model includes an outer mold 1, an inner mold 2, a rubber mold 3 and a spring bolt 4. Put in the reinforcement skeleton, assemble the outer mold 1, and stretch the longitudinal prestressed reinforcement (see figure 1 );

[0033] b. Set the assembled outer mold 1 onto the upright inner mold 2 and connect with spring bolts 4;

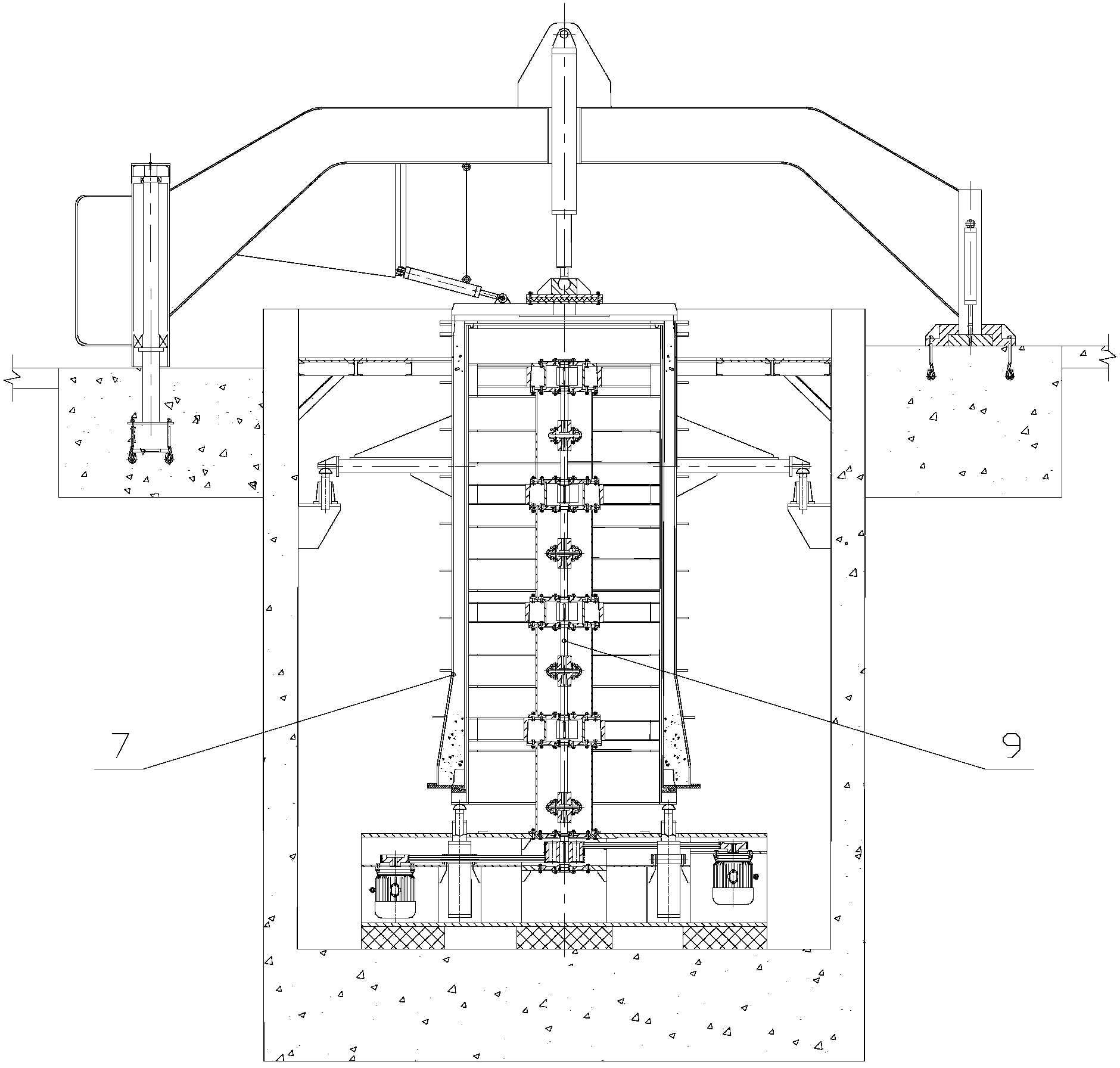

[0034] c. The inner and outer molds are hoisted together to the mandrel vibrator, so that the model 7 and the mandrel vibrator 9 are tightly fitted through the locking device (see image 3 );

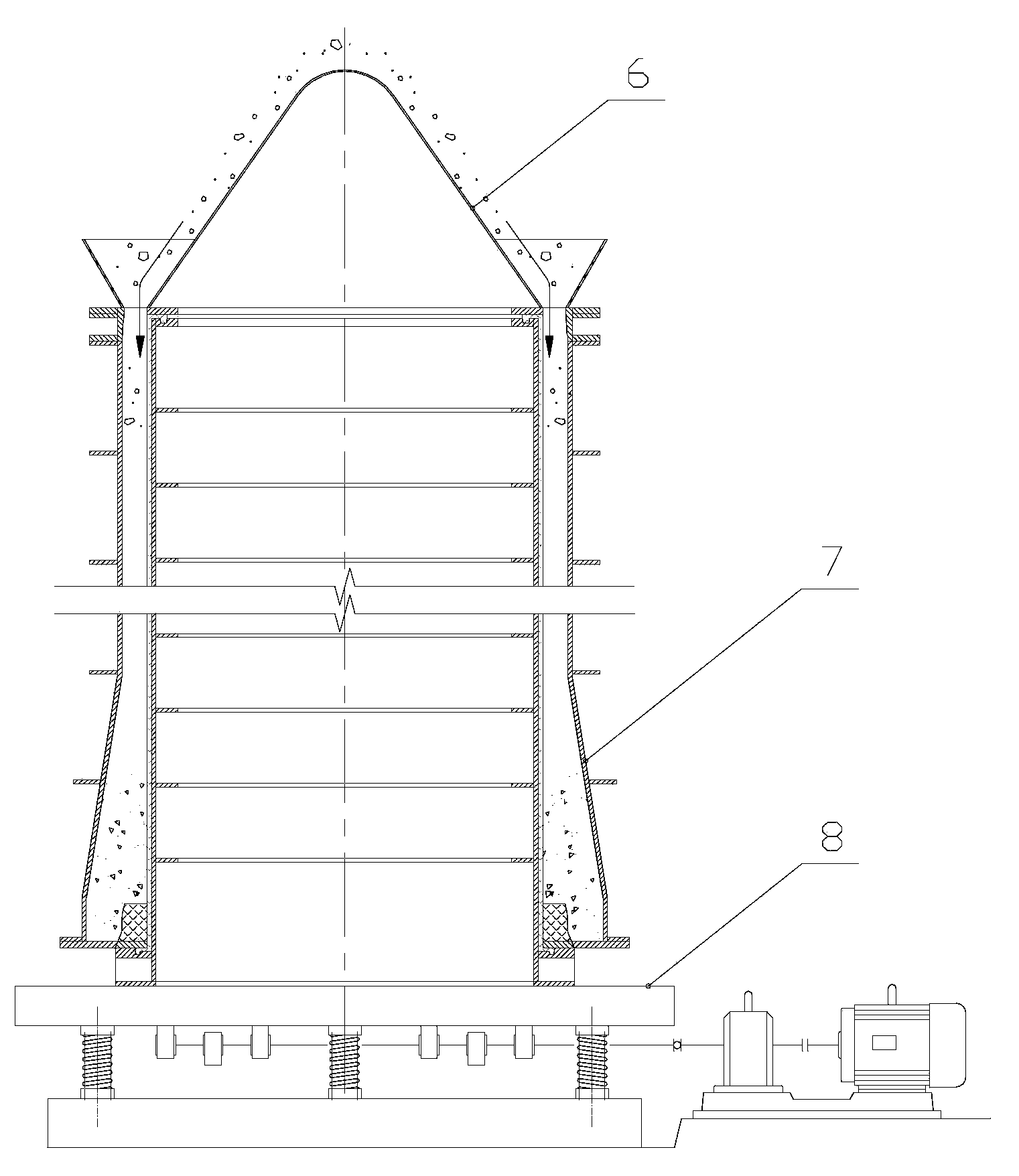

[0035] d. Install feeding hopper 8 above the model;

[0036] e. Start the mandrel vibrating device and feed the material while vibrating until the concrete mixture is filled with the model; the mandrel vibrating device is driven by a motor to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com