Apparatus for improving light beam quality of solid laser by using in-chamber adaptive optical technology

A solid-state laser, adaptive optics technology, applied in lasers, laser parts, optics, etc., can solve the problems of loss, multi-mode oscillation, inapplicability, etc., and achieve the effect of improving beam quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

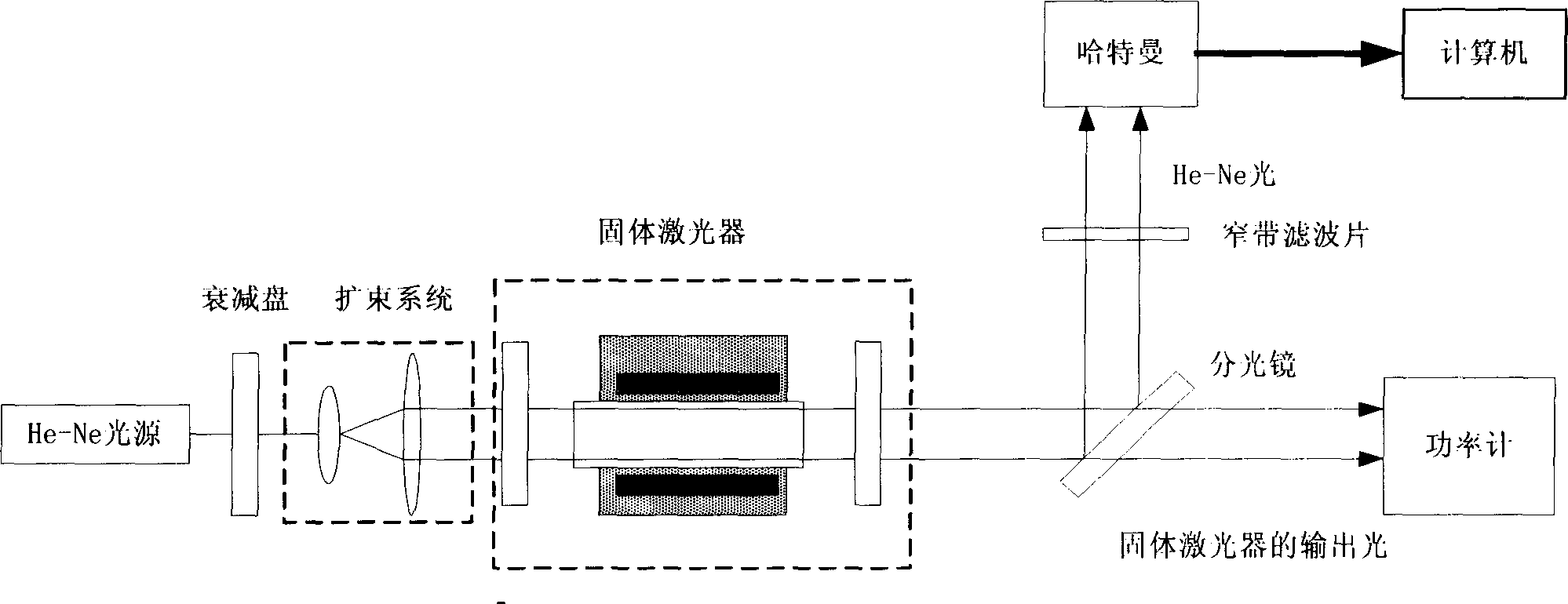

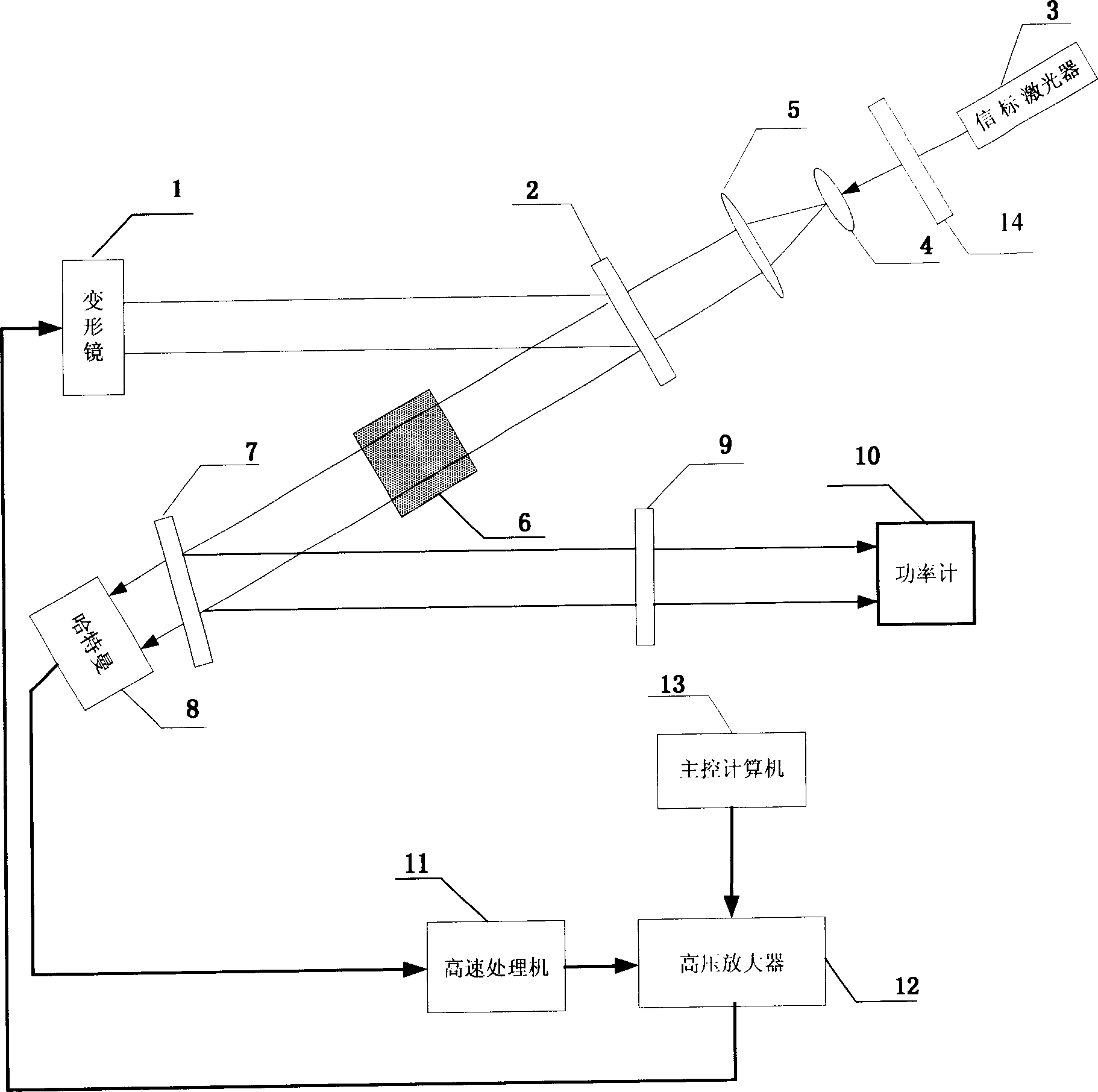

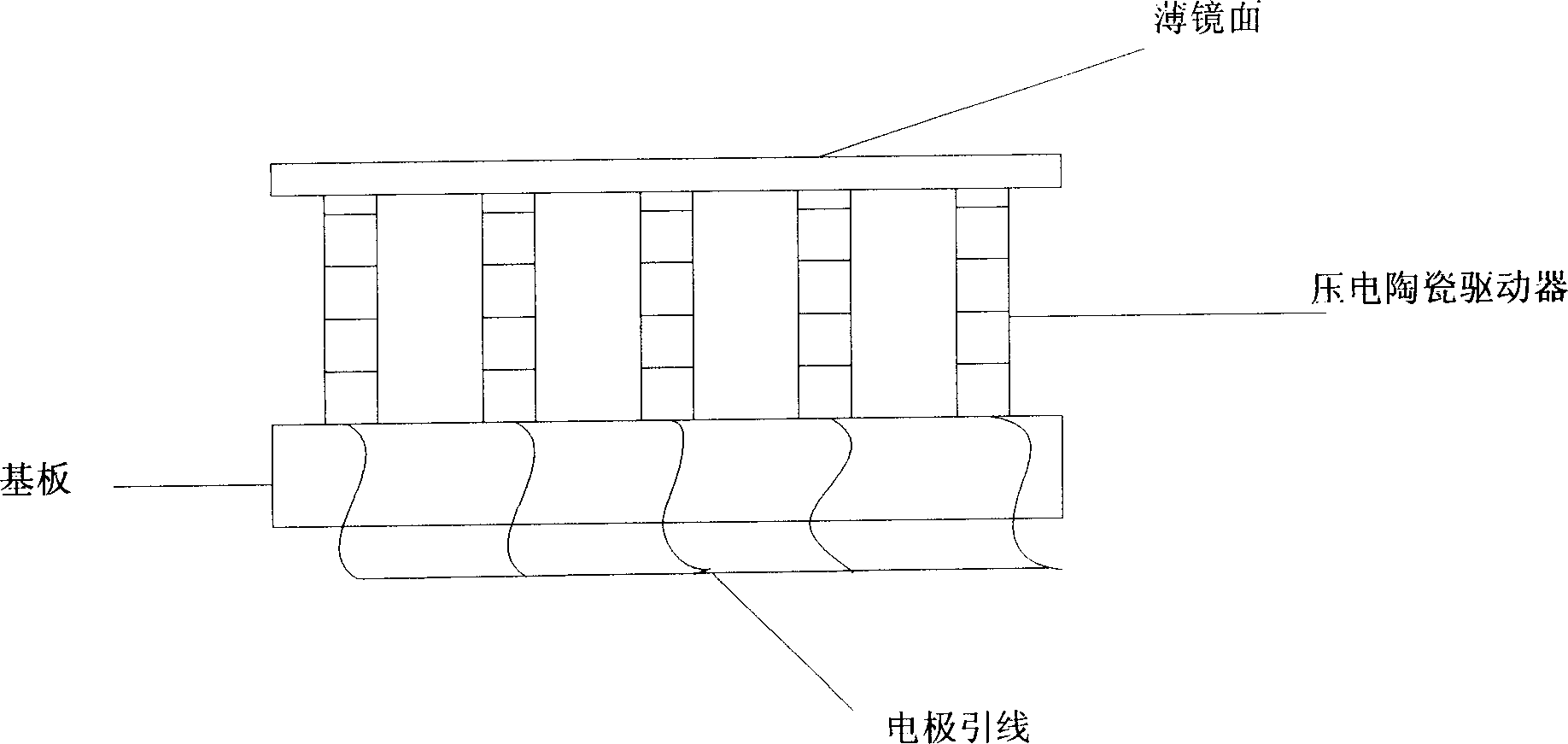

[0021] Such as figure 2 As shown, it is mainly composed of the following components: the deformable mirror 1 as the wavefront corrector is the core active device of the device, which can correct the aberrations generated in the solid-state laser cavity in real time; the concave mirror 2 is used to introduce the beacon light At the same time, it is used to match the beam diameter in the cavity with the diameter of the deformable mirror; the laser 3 is not only used as a beacon light source for detecting aberrations in the solid laser cavity, but also used to calibrate the Hartmann sensor; the variable density attenuation disk 14 is used to adjust The light intensity of the beacon light; the beam expansion system consists of two lenses 4 and 5, which are used to expand the radius of the laser beam emitted by the beacon light source; the gain medium 6 is the material basis for the laser to generate laser light, and it is also the most important intracavity aberration The source of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com