Hot-rolled seamless steel tube and deformation and phase transformation integrated type structure regulation and control method thereof

A technology of seamless steel pipe and structure, applied in temperature control, heat treatment furnace, heat treatment equipment, etc., can solve problems such as deterioration of mechanical properties, achieve the effects of improving structure performance, saving off-line heat treatment process, and reducing consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

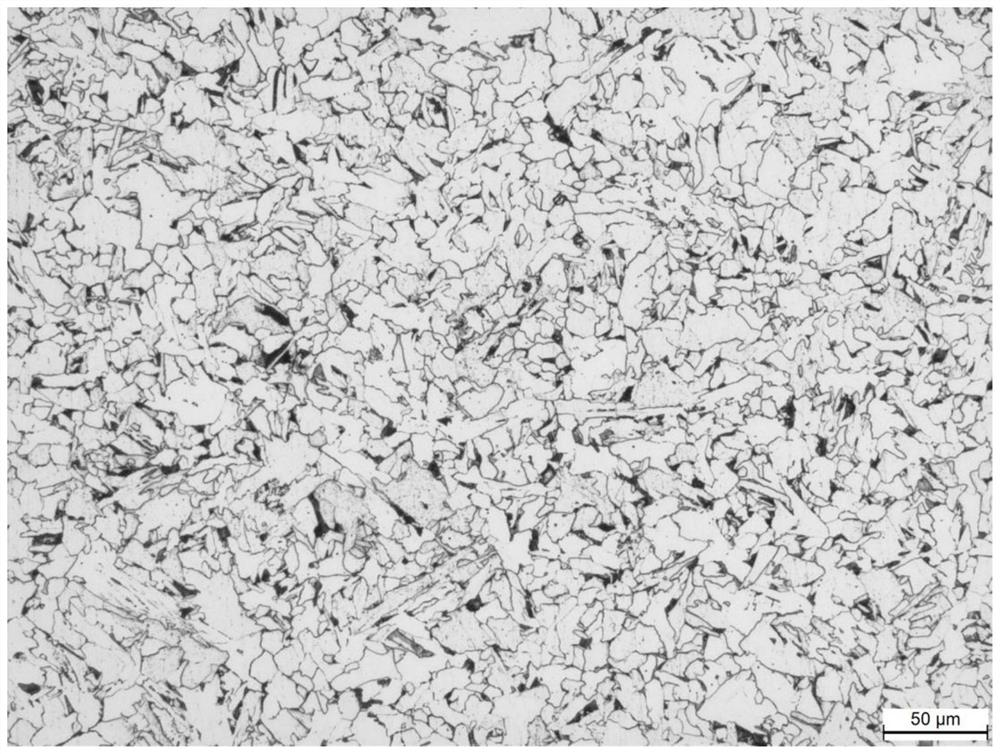

Embodiment 1

[0058] A hot-rolled seamless steel pipe deformation and phase transformation integrated microstructure control method, comprising the following steps:

[0059] Step 1: Smelting and billet making

[0060] The molten iron is smelted into molten steel using a converter. When the temperature of the molten steel is 1660°C and the mass fraction of carbon in the molten steel is 0.05%, the mass fraction of phosphorus is 0.02%, and the mass fraction of sulfur is 0.03%, the steel is tapped, and silicon deoxidation alloying is added during the tapping process. , the mass fraction of dissolved oxygen in molten steel is 0.005%, to obtain molten steel after furnace;

[0061] Carry out LF refining, slagging and desulfurization, and adjust the composition of molten steel. The refining time is 25 minutes, and the temperature is raised to 1550°C; The core wire is made of steel strip and alloy powder with particle size less than 3mm, the outer diameter is 10mm, the chemical composition mass per...

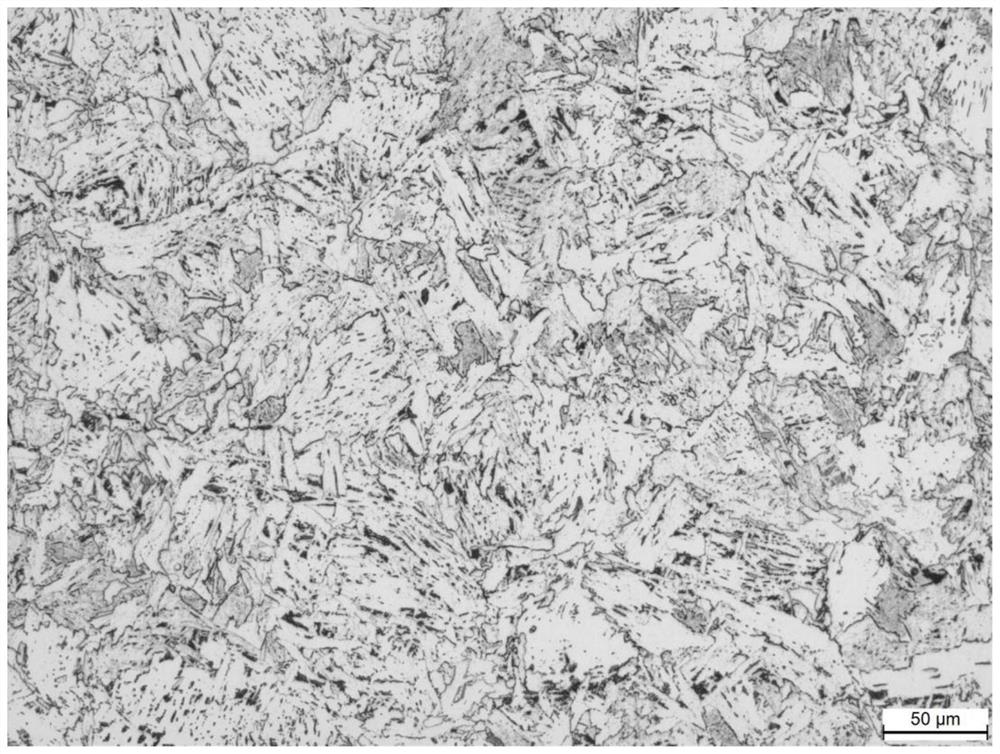

Embodiment 2

[0073] A hot-rolled seamless steel pipe deformation and phase transformation integrated microstructure control method, comprising the following steps:

[0074] Step 1: Smelting and billet making

[0075] Use a converter to smelt molten iron and scrap steel (according to the mass ratio, molten iron:scrap = 5:1) into molten steel. When the fraction is 0.005%, the steel is tapped, and manganese is added during the tapping process for deoxidation alloying, and the dissolved oxygen mass fraction of the molten steel is 0.015%, to obtain molten steel after the furnace;

[0076] Carry out LF refining, slagging and desulfurization, and adjust the composition of molten steel. The refining time is 45 minutes, and the temperature is raised to 1600°C. After LF refining, RH degassing and inclusion removal treatment is carried out, so that the number of inclusions with a size above 5 μm in the steel is less than 100 pieces / mm 3; When the dissolved oxygen mass fraction of molten steel is 0.0...

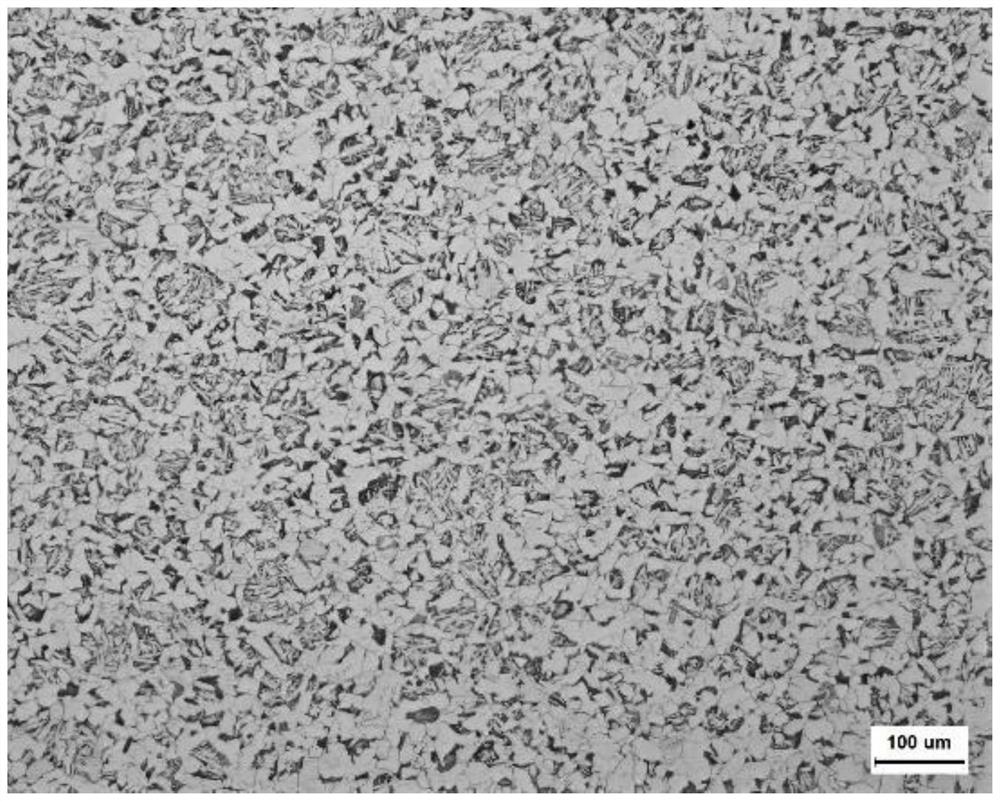

Embodiment 3

[0087] A hot-rolled seamless steel pipe deformation and phase transformation integrated microstructure control method, comprising the following steps:

[0088] Step 1: Smelting and billet making

[0089] Use an electric furnace to smelt scrap steel into molten steel. When the temperature of the molten steel is 1650°C and the mass fraction of carbon in the molten steel is 0.12%, the mass fraction of phosphorus is 0.03%, and the mass fraction of sulfur is 0.01%, the steel is tapped, and aluminum is added during the tapping process for deoxidation. Alloying, the mass fraction of dissolved oxygen in molten steel is 0.001%, and molten steel after furnace is obtained;

[0090] Carry out LF refining, slagging and desulfurization, and adjust the composition of molten steel. The refining time is 75 minutes, and the temperature is raised to 1650°C. After LF refining, VD degassing and inclusion removal treatment is carried out, so that the number of inclusions with a size above 5 μm in t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com