Gas detonation driven ultra-high-speed launching system

A launch system, ultra-high-speed technology, used in aerodynamic tests, measurement of blasting force, instruments, etc., can solve problems such as limited gunpowder transportation and storage, uneven projectile acceleration, limited transportation and storage, etc., to achieve easy cleaning. and maintenance, high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

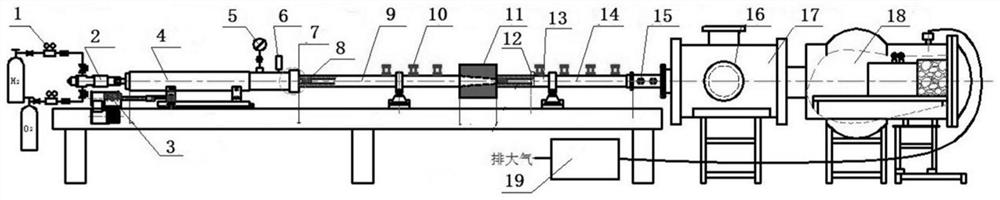

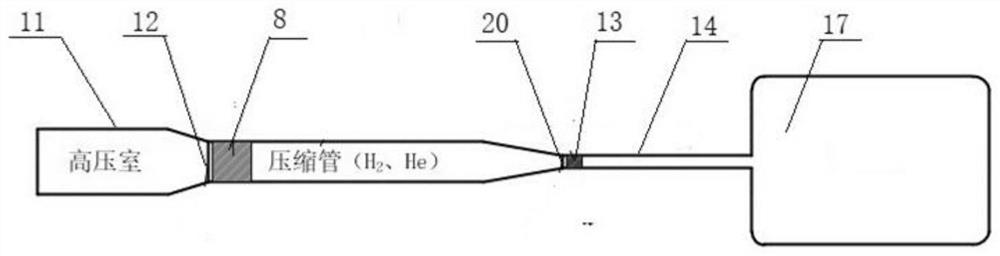

[0057] like figure 1 and figure 2 As shown, a gas detonation-driven ultra-high-speed launch system includes a hydrogen-oxygen charging system 1, a launch body, a test chamber 17, a buffer box 18 and a vacuum system,

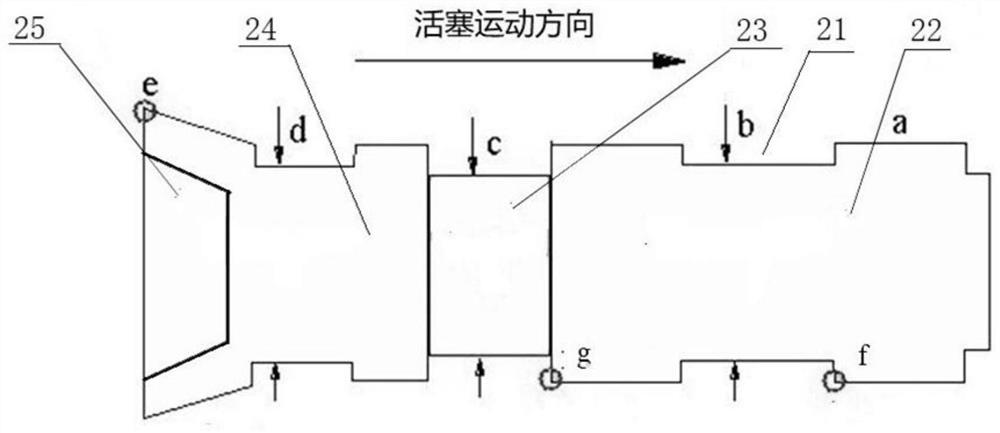

[0058] The launching main body is set as a detonation secondary light gas cannon mechanism, and the first stage adopts a forward detonation method to control the shock wave to oscillate back and forth in the area between the wall surface of the left end of the detonation tube 4 and the rear wall surface of the piston 8, and the high pressure gas passes through the shock wave. Push the piston 8 to move, and after the second stage compresses the light gas through the high-speed motion of the piston 8 to reach the film breaking pressure, pushes the projectile 13 to move;

[0059] The launching main body is sequentially connected with a detonation tube 4, a compression tube 9, a film clipper 7, and a launch tube 14. The front end of the detonation tube 4 is provide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com