Flesh and bone cutter

A technology for cutting knives and flesh, which is applied in metal processing and other directions, can solve the problems of not considering the cutting characteristics of flesh and bones, a large number of bones and meat, and rough sawing surfaces, so as to overcome poor cutting quality, less flesh and flesh scraps, and smooth good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] Below by embodiment the content of the present invention is specified:

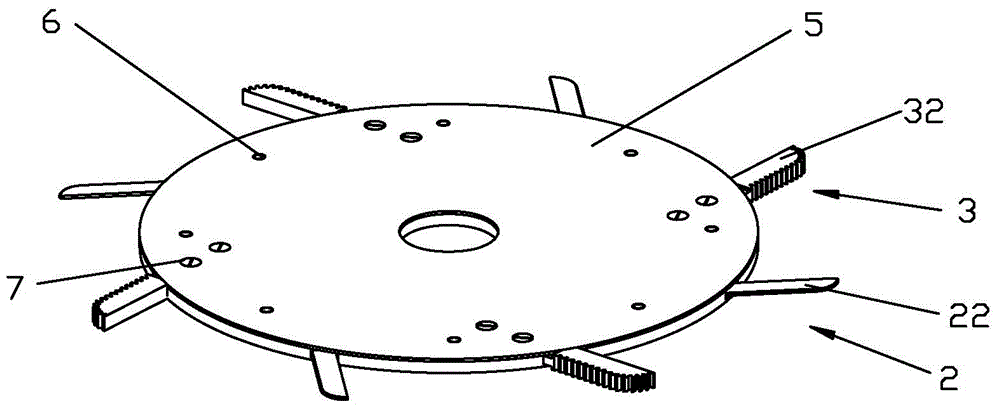

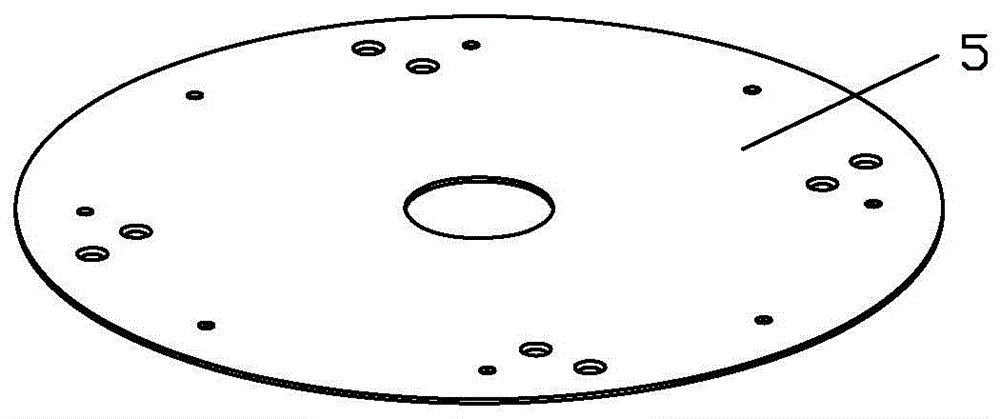

[0042] Please check Figure 1-8 , a bone and meat cutting tool, including a disc-shaped outer cover 5 and a base plate 1, the outer cover 5 is screwed on the base plate 1 through 8 hexagon socket head screws 6; the outer cover 5 and the base plate 1 have the same radius for installation The central hole has the same radius as the motor rotor, and the outer cover 5 and the base plate 1 are connected to the motor main shaft through the central hole, and the motor can be used to drive the meat cutting tool to rotate to achieve cutting.

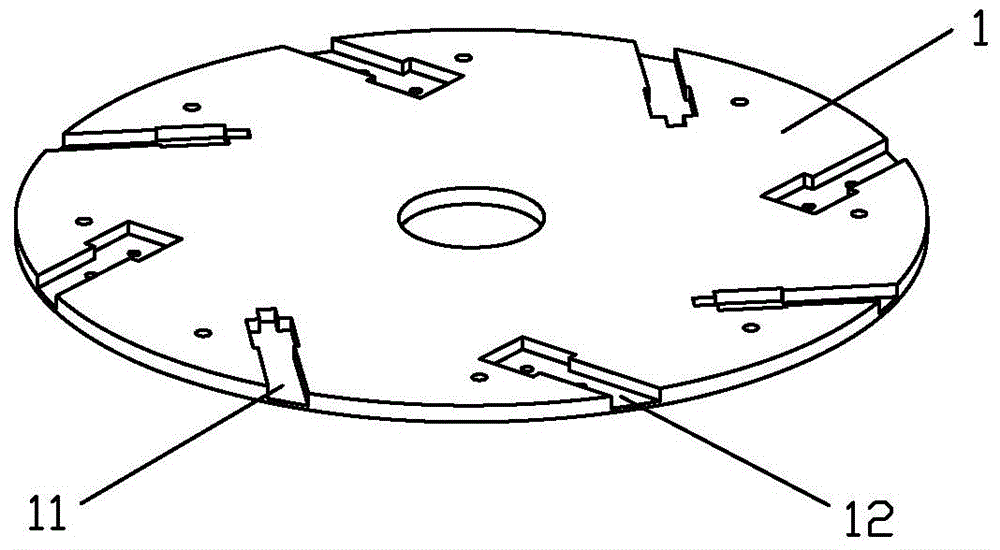

[0043] There are four T-shaped first slots 11 and four T-shaped second slots 12 on the base plate 1, the first slots 11 and the second slots 12 alternate along the base plate 1 circumference Arranged at intervals, and the length direction of the first slot 11 and the second slot 12 form an angle A with the tangent at the intersection with the periphery of the base pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com