Sizing coating machine

A coating machine and slurry technology, which is used in textile processing machine accessories, textile and papermaking, and textile material processing, etc. Flatness and other issues to achieve the effect of improving softness and printing adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

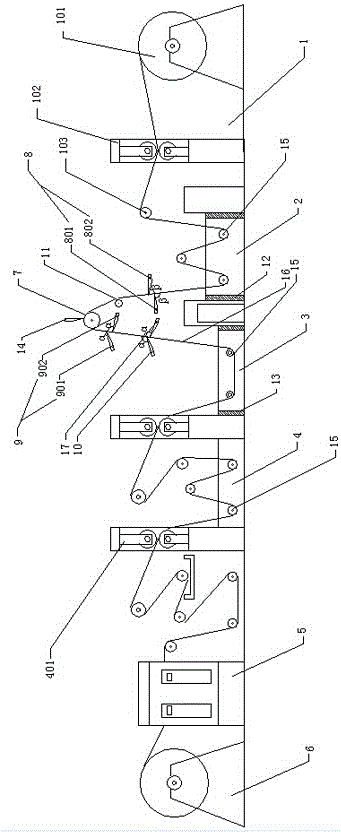

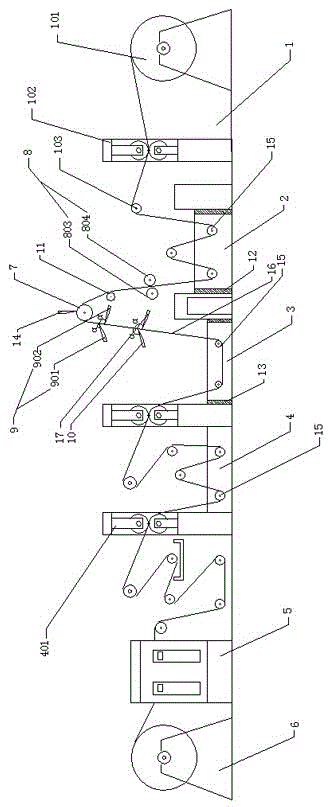

[0022] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0023] Such as figure 1 As shown, the embodiment of the present invention includes a cloth feeding device 1 , a slurry tank 2 , a curing tank 3 , a cleaning tank 4 , a drying device 5 and a winding device 6 . The cloth feeding device 1, the slurry tank 2, the curing tank 3, the cleaning tank 4, the drying device 5 and the winding device 6 are arranged in sequence.

[0024] Such as figure 1 As shown, the cloth feeding device 1 of the embodiment of the present invention includes an uncoiling roller 101 for unwinding the cloth, and an uncoiling pressure roller 102 is arranged behind the uncoiling roller 101, and the uncoiling pressure roller 102 is used to flatten the uncoiled cloth while stabilizing the cloth feeding speed , an opening roller 103 is provided at the joint between the cloth feeding device 1 and the stock tank 2 .

[0025] Such as figure 1 As ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com