Stone water-free paper-making method and flow

A stone and process technology, applied in the field of synthetic paper production, can solve problems such as unstable product quality, late start of synthetic paper, and impact on development, and achieve the effects of strong ink adaptability, fast production speed, and strong printing adaptability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

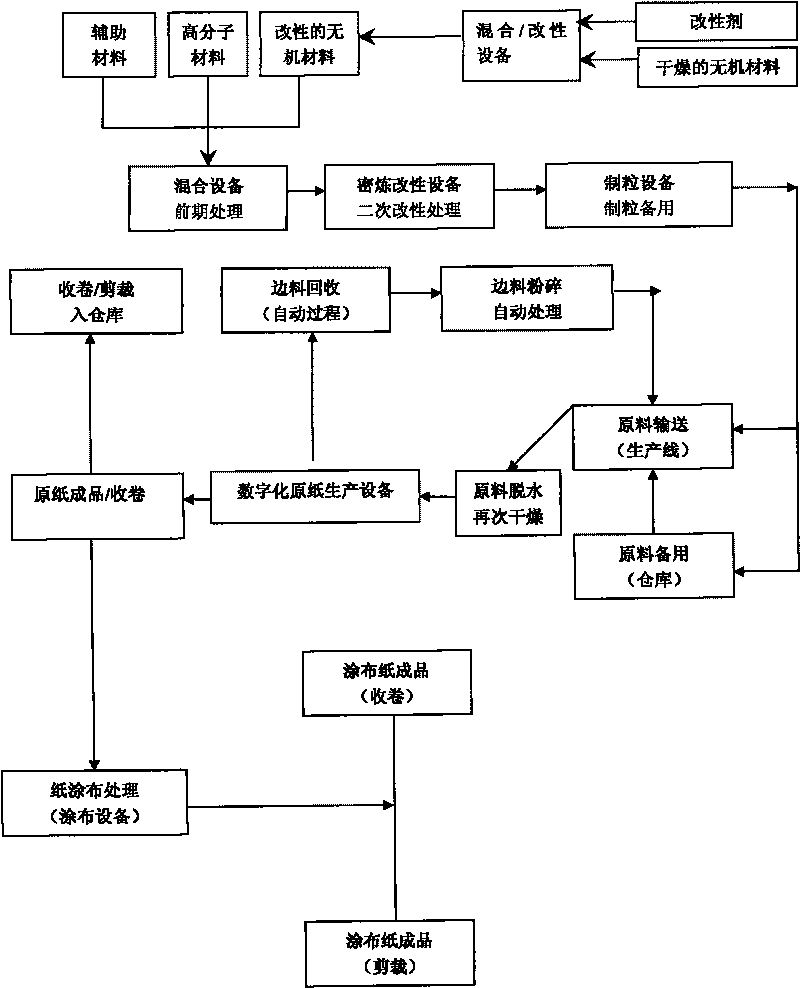

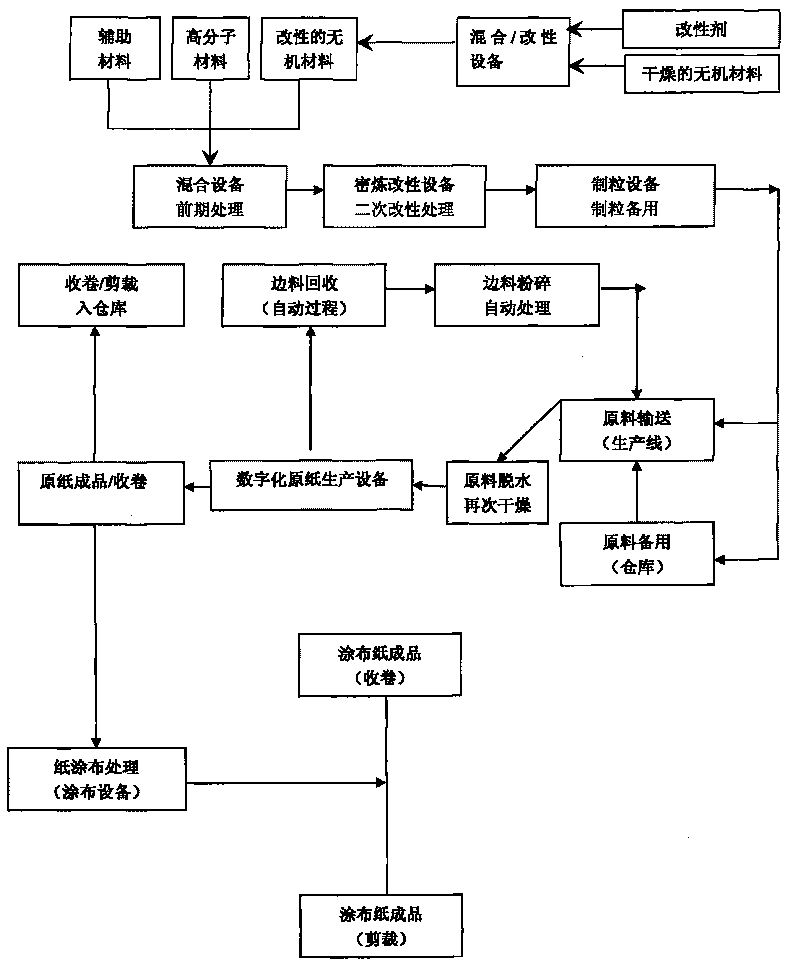

Image

Examples

Embodiment 1

[0035] A method and process for making paper without water from stone, including the following steps:

[0036] (1) Dry the inorganic material at 100°C so that the moisture content of the inorganic material is less than 0.5%;

[0037] (2) Add inorganic materials and modifiers to the mixing / modification equipment and mix to modify the inorganic materials;

[0038] (3) Add the activated modified inorganic materials, organic materials and additives to the mixing equipment, mix them evenly, and transport them to the modification equipment for secondary modification treatment (banbury);

[0039] (4) Granulate the material processed through the above steps with granulation equipment;

[0040] (5) The finished raw material pellets are transported through the raw material conveying equipment to the raw material drying equipment to be dried again at 100°C. The dried raw materials are directly transported to the flow calender, and are produced after being extruded and stretched by the flow calende...

Embodiment 2

[0053] A method and process for making paper without water from stone, including the following steps:

[0054] (1) Dry the inorganic material at 110°C so that the moisture content of the inorganic material is less than 0.3%;

[0055] (2) Add inorganic materials and modifiers to the mixing / modification equipment and mix to modify the inorganic materials;

[0056] (3) Add the activated modified inorganic materials, organic materials and additives to the mixing equipment, mix them evenly, and transport them to the modification equipment for secondary modification treatment (banbury);

[0057] (4) Granulate the material processed through the above steps with granulation equipment;

[0058] (5) The finished raw material pellets are transported through the raw material conveying equipment to the raw material drying equipment to be dried again at 110°C. The dried raw material is directly transported to the flow calender, and is produced after extrusion by flow calendering and stretching by the...

Embodiment 3

[0071] A method and process for making paper without water from stone, including the following steps:

[0072] (1) Dry the inorganic material at 105°C so that the moisture content of the inorganic material is less than 0.4%;

[0073] (2) Add inorganic materials and modifiers to the mixing / modification equipment and mix to modify the inorganic materials;

[0074] (3) Add the activated modified inorganic materials, organic materials and additives to the mixing equipment, mix them evenly, and transport them to the modification equipment for secondary modification treatment (banbury);

[0075] (4) Granulate the material processed through the above steps with granulation equipment;

[0076] (5) The finished raw material pellets are transported to the raw material drying equipment through the raw material conveying equipment to be dried again at 105°C. The dried raw material is directly transported to the flow calender, and is produced after being extruded and stretched by the flow calender. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com