White manila board and preparation method thereof

A whiteboard paper and gray bottom technology, applied in the field of papermaking, can solve the problems of large chemicals and power consumption, large loss of raw materials, low yield, etc., and achieve lower production costs, lower whiteness requirements, and good printing adaptability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

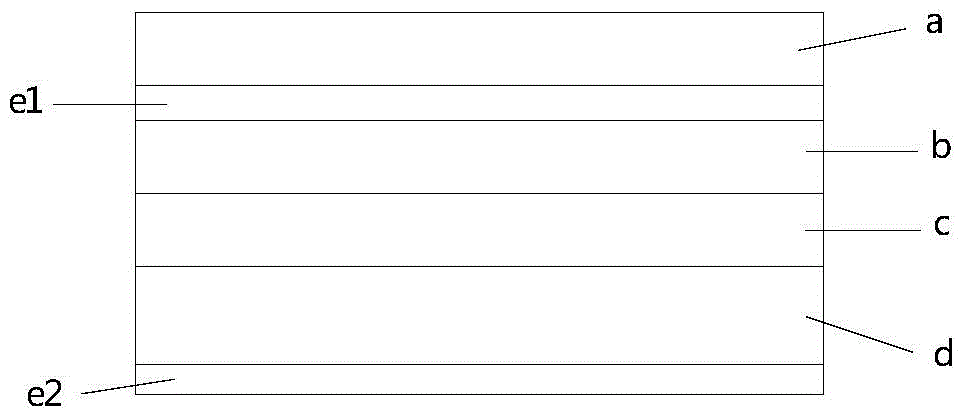

Image

Examples

Embodiment 1

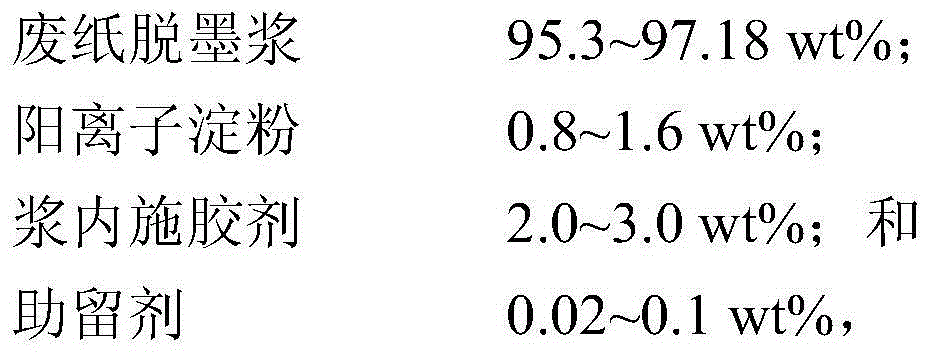

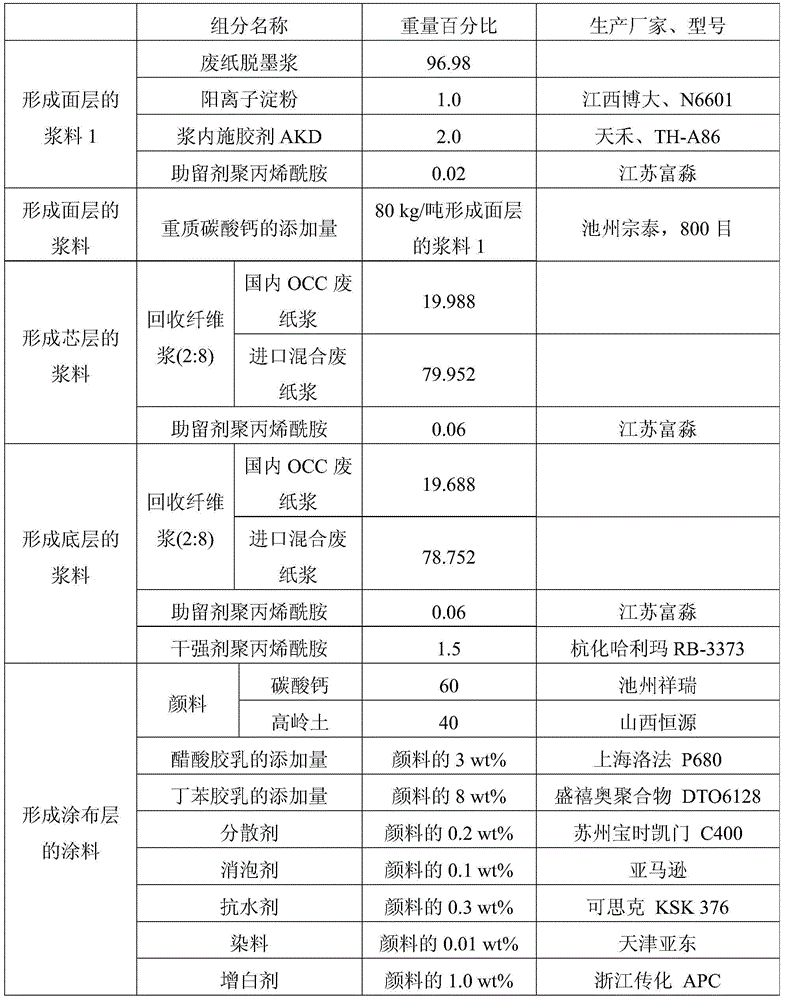

[0056] (1) Configure each layer of slurry

[0057] Form the slurry of surface layer, core layer and bottom layer according to the composition preparation shown in table 1 respectively;

[0058] (2) Preparation of base paper

[0059] ①Wet paper sheet is formed by three-layer forming wire

[0060] Each layer of slurry is transported to the headbox of the paper machine through its own feeding system, and a certain concentration of the above-mentioned layers of slurry is applied to the three-layer forming wire to form a wet paper sheet, and then the above wet paper sheet is dehydrated and compounded. and high-vacuum suction to produce base paper with a dryness of more than 22%, wherein the three-layer forming wire is arranged in sequence along the horizontal direction, and a top wire is arranged on the bottom forming wire to enhance the dehydration effect and improve the evenness of the base paper , wherein, the slurry concentration forming the surface layer is 0.3wt%, the slurr...

Embodiment 2

[0084] (1) Configure each layer of slurry

[0085] Prepare the slurry forming surface layer, core layer and bottom layer according to the composition shown in table 3 respectively;

[0086] (2) Preparation of base paper

[0087] ①Wet paper sheet is formed by three-layer forming wire

[0088] Each layer of slurry is transported to the headbox of the paper machine through its own feeding system, and a certain concentration of the above-mentioned layers of slurry is applied to the three-layer forming wire to form a wet paper sheet, and then the above wet paper sheet is dehydrated and compounded. and high-vacuum suction to produce base paper with a dryness of more than 22%, wherein the three-layer forming wire is arranged in sequence along the horizontal direction, and a top wire is arranged on the bottom forming wire to enhance the dehydration effect and improve the evenness of the base paper , wherein, the slurry concentration forming the surface layer is 0.3wt%, the slurry co...

Embodiment 3

[0112] (1) Configure each layer of slurry

[0113] Prepare the slurry forming surface layer, core layer and bottom layer according to the composition shown in table 5 respectively;

[0114] (2) Preparation of base paper

[0115] ①Wet paper sheet is formed by three-layer forming wire

[0116] Each layer of slurry is transported to the headbox of the paper machine through its own feeding system, and a certain concentration of the above-mentioned layers of slurry is applied to the three-layer forming wire to form a wet paper sheet, and then the above wet paper sheet is dehydrated and compounded. and high-vacuum suction to produce base paper with a dryness of more than 22%, wherein the three-layer forming wire is arranged in sequence along the horizontal direction, and a top wire is arranged on the bottom forming wire to enhance the dehydration effect and improve the evenness of the base paper , wherein, the slurry concentration forming the surface layer is 0.4wt%, the slurry co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Basis weight | aaaaa | aaaaa |

| Basis weight | aaaaa | aaaaa |

| coating mass | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com