A car horn ringing mechanism

A technology for horns and automobiles, which is applied to vehicle components, sound signal devices, signal devices, etc., can solve the problems of weak universality of parts and high cost, and achieve performance advantages, simplify design, and reduce costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

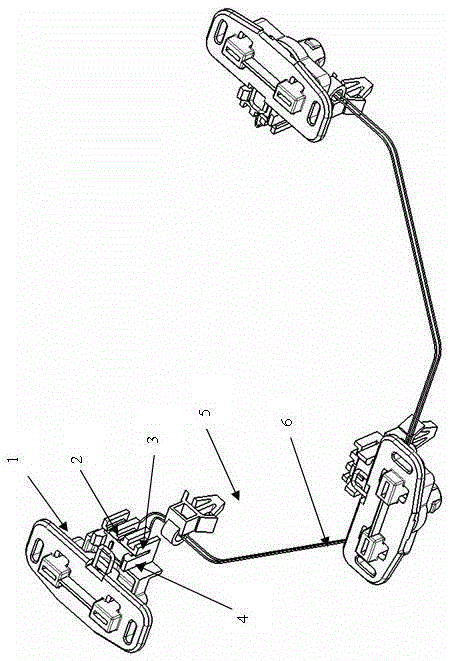

[0029] figure 1 As shown, the present invention has three identical structural units, and in practical application, there may be more than three structural units, and one of the structural units will be described below. The fixed bracket 2 is installed under the support plate 1, the support spring 4 is interposed between the support plate 1 and the fixed bracket 2, the micro switch 3 is clamped in the fixed bracket 2, and the movement stroke of the support plate is greater than the touch point on the support plate The distance from the touch end of the micro switch. The wire 6 is used to connect the same structural units in parallel, and the wire harness card 5 is used to fix the wire 6 .

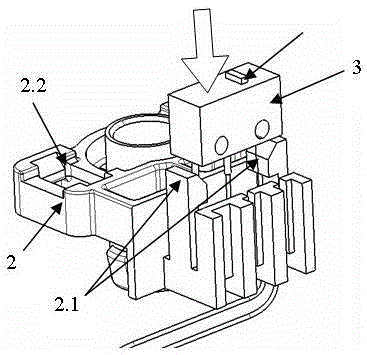

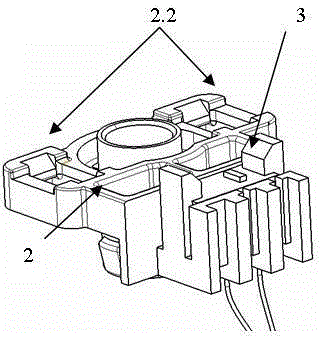

[0030] Such as figure 2 and image 3 As shown, the fixing bracket 2 is a plastic part, and there are buckles 2.1 and square holes 2.2 on both sides of the fixing bracket 2. The buckles 2.1 on both sides are deformed to the outside as the micro switch 3 is pressed in, and when the micro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com