Magnesium jade porcelain and production method thereof

A production method, the technology of magnesia jade porcelain, applied in the field of magnesia jade porcelain and its production, to achieve the effect of reducing production cost, good heat insulation, and good heat preservation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

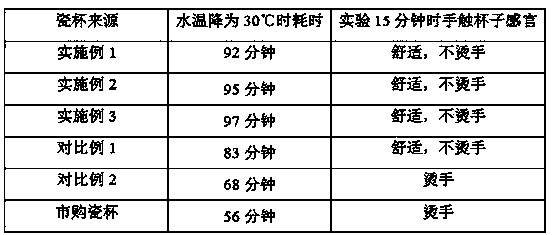

Examples

Embodiment 1

[0027] The talc raw material is calcined at 1400°C to obtain calcined talc. The serpentine mineral powder (yellow-green antigorite) was leached with 1mol / L hydrochloric acid for 0.5 hours, and the filter residue was taken as serpentine waste. Weigh the raw materials according to the weight ratio: 45 parts of calcined talc, 35 parts of clay, 20 parts of feldspar and 5 parts of serpentine waste (calculated as dry product). Adding water to the raw materials, ball milling, sieving, iron removal, pressure filtration, aging, mud refining under reduced pressure, and molding to obtain a green body. The biscuit is put into the kiln for biscuit firing, the bisque firing temperature is 850-900°C, and the time is 3.5 hours; the fired biscuit is taken out and colored, and then glazed, and the glaze firing temperature is 1200-1280°C, and the time is 5 hours; After burning, keep it warm for 0.5 hours and then take it out. Serve. The obtained magnesia jade porcelain is light yellow-green, t...

Embodiment 2

[0029] The talc raw material is calcined at 1300°C to obtain calcined talc. The serpentine mineral powder (dark green lizardite) was leached with 2mol / L hydrochloric acid for 0.5 hours, and the filter residue was taken as serpentine waste. Weigh the raw materials according to the weight ratio: 50 parts of calcined talc, 30 parts of clay, 10 parts of feldspar and 8 parts of serpentine waste (calculated as dry product). Adding water to the raw materials, ball milling, sieving, iron removal, pressure filtration, aging, mud refining under reduced pressure, and molding to obtain a green body. The biscuit is put into the kiln for biscuit firing, the bisque firing temperature is 850-900°C, and the time is 3 hours; after taking out the fired biscuit, it is colored and then glazed, and the glaze firing temperature is 1200-1280°C, and the time is 6 hours; After burning, keep it warm for 0.5 hours and then take it out. Serve. The obtained magnesia jade porcelain is dark green, transpar...

Embodiment 3

[0031] The talc raw material is calcined at 1300°C to obtain calcined talc. The serpentine mineral powder (light yellow chrysotile) was leached with 1.5mol / L hydrochloric acid for 0.5 hours, and the filter residue was taken as serpentine waste. Raw materials were weighed according to weight ratio: 47 parts of calcined talc, 33 parts of clay, 15 parts of feldspar and 10 parts of serpentine waste (calculated as dry product). Adding water to the raw materials, ball milling, sieving, iron removal, pressure filtration, aging, mud refining under reduced pressure, and molding to obtain a green body. Put the biscuit into the kiln for biscuit firing, the bisque firing temperature is 850-900°C, and the time is 4 hours; after taking out the fired biscuit and coloring it, then glaze firing, the glaze firing temperature is 1200-1280°C, and the time is 5 hours; After burning, keep it warm for 0.5 hours and then take it out. Serve. The obtained magnesia jade porcelain is light yellow in co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com