Display glass protection screen with antifogging coat and LCD using same

An anti-fog coating and display technology, applied in coatings, instruments, layered products, etc., can solve the problems of reducing the surface reflectivity of protective screen materials, prone to rainbows on the surface, and difficult to control film thickness, achieving low cost, The effect of high production efficiency and high light transmittance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

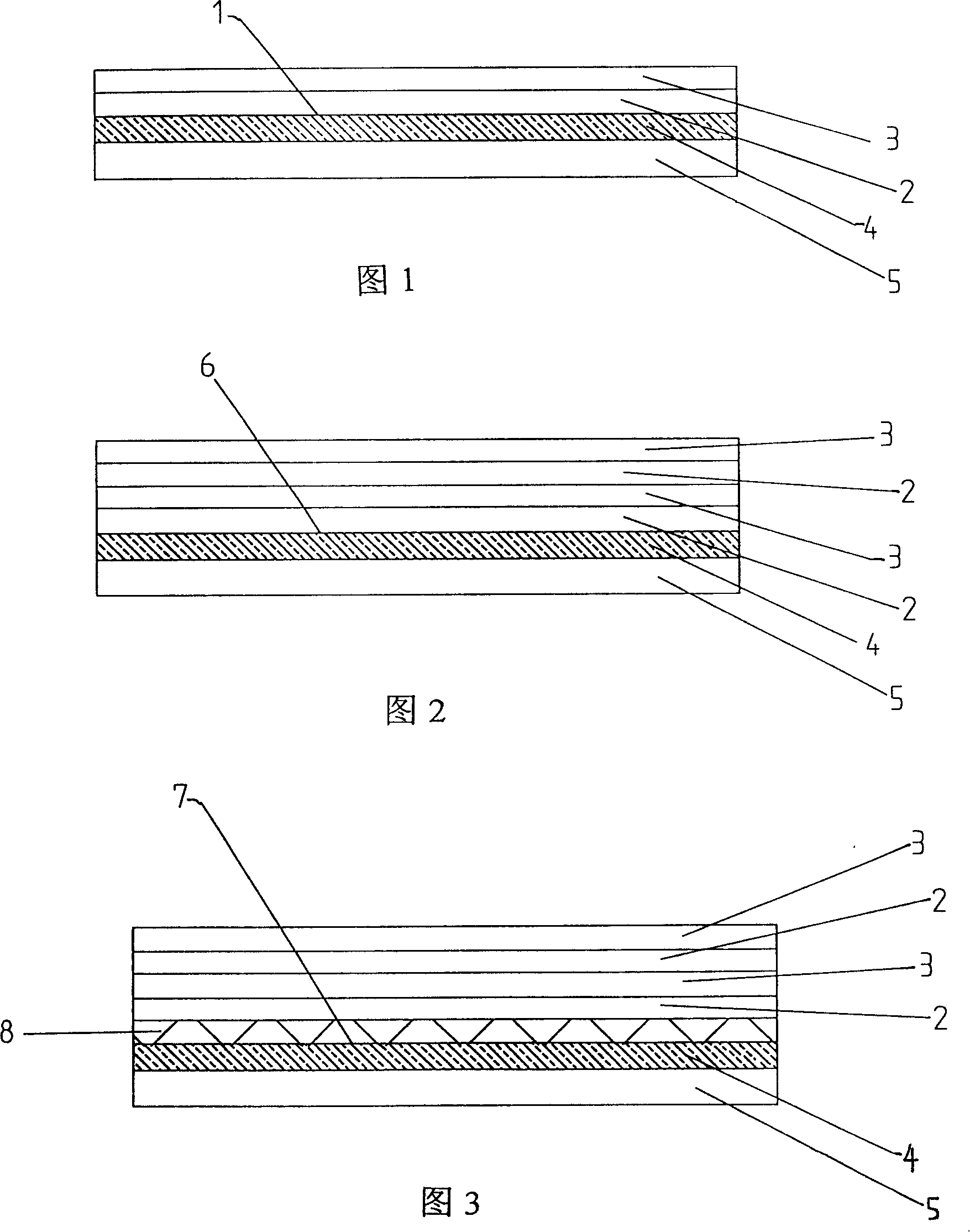

[0018] Fig. 1 has provided present embodiment 1 figure. Referring to Fig. 1, the display glass protective screen 1 with anti-fog coating is made of a transparent tempered glass substrate 4 and a two-layer anti-reflection and anti-reflection TiO deposited sequentially by vacuum magnetron sputtering on one side of the substrate 4. 2 Coating 2 and SiO 2 The film layer 3 is composed of an acrylic resin layer 5 coated with an anti-fog function that is first heated and then photocured on the other side of the substrate, and the formed structure is SiO 2 / TiO 2 / Glass Substrate / Acrylic Resin Layered Display Glass Protective Screen 1 with Antifog Coating. Coating two layers of anti-reflection and anti-reflection coatings on one side of the substrate 4, the light transmittance is greater than 94%, and the double-sided superimposed reflectance is less than 2%. The optimized thickness of the coating is: TiO 2 10~16nm, SiO 2 It is 90~120nm. Adding fluorocarbon active agent to the acr...

Embodiment 2

[0020] Figure 2 shows the structure diagram of Embodiment 2. This embodiment 2 is basically the same as embodiment 1, the difference is that one side of the substrate 4 is coated with four layers of anti-reflection and anti-reflection coating layers, and the formation structure is SiO 2 / TiO 2 / SiO 2 / TiO 2 / Glass substrate / acrylic resin layer anti-fog coating display glass protective screen 6, the light transmittance is greater than 95%, the double-sided superimposed reflectivity is less than 1.5%, and the thickness of the coating is optimized in order: SiO 2 100~115nm / TiO 2 30~36nm / SiO 2 36~45nm / TiO 2 It is 8~12nm.

Embodiment 3

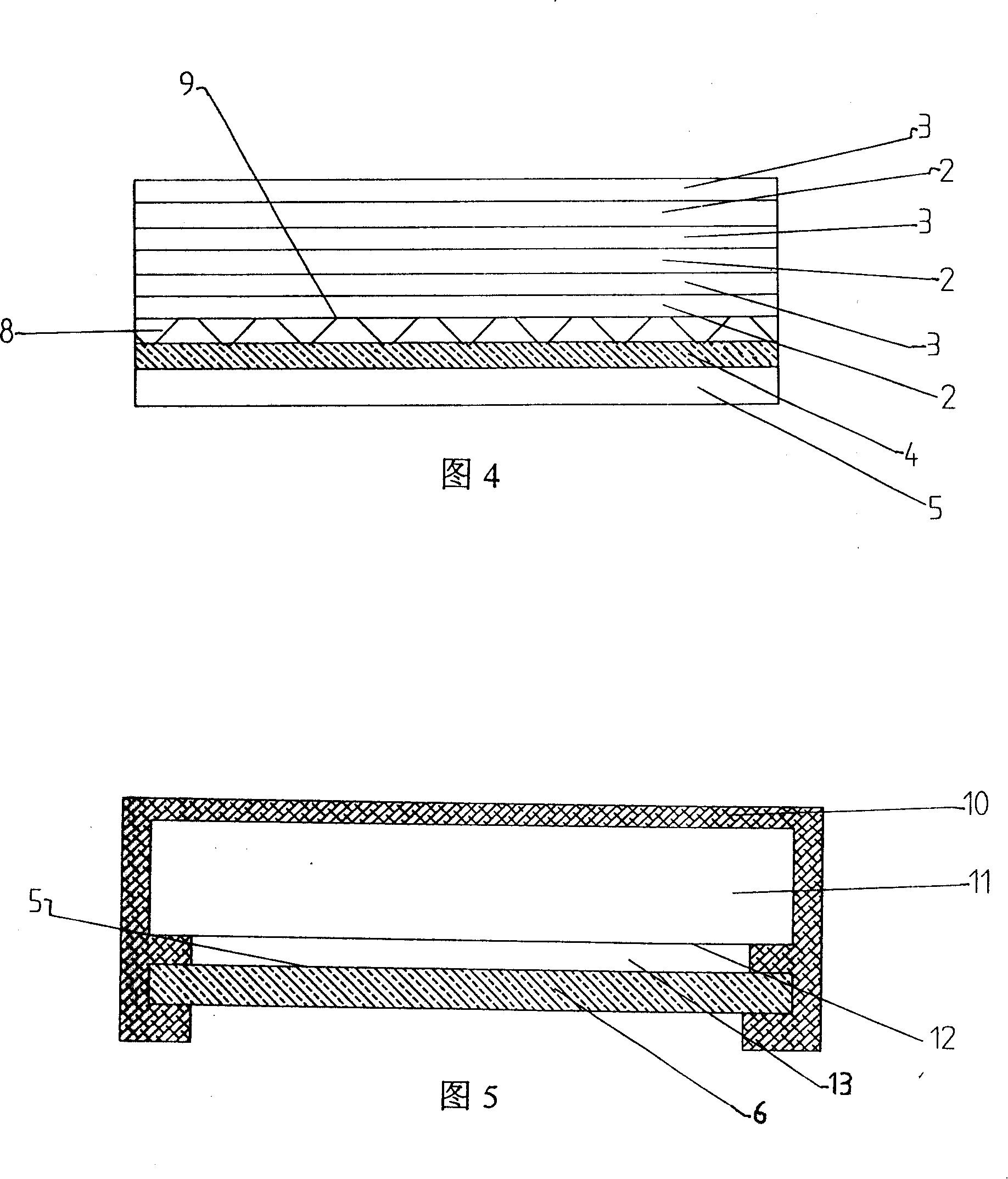

[0022] Fig. 3 has provided present embodiment 3 figure, and present implementation is basically the same as embodiment 2, and difference is that one side of substrate 4 is coated with four layers of anti-reflection and anti-reflection coatings, and the anti-reflection and anti-reflection coatings on this side are the same as A layer of antistatic layer 8 is deposited between the glass substrates by vacuum magnetron sputtering. The antistatic layer 8 is an aluminum-doped zinc oxide (AZO) semiconductor film layer, and the other side is coated with anti-fog function. cured acrylic layer 5, while forming a structure of SiO 2 / TiO 2 / SiO 2 / TiO 2 / AZO / glass substrate / acrylic resin layer with anti-fog coating, high light transmittance glass protective screen 7 with antistatic function, the light transmittance is greater than 96%, and the surface resistance of the antistatic surface is less than 10 11 Ω, double-sided superimposed reflectivity is less than 1.5%, and the thickness o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com