Anti-fogging three-dimensional cold laminating composite paper

A composite paper, three-dimensional technology, applied in papermaking, packaging paper, paper coating and other directions, can solve the problems of visual effect, three-dimensional effect and anti-fogging effect is not ideal, and achieve good three-dimensional effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

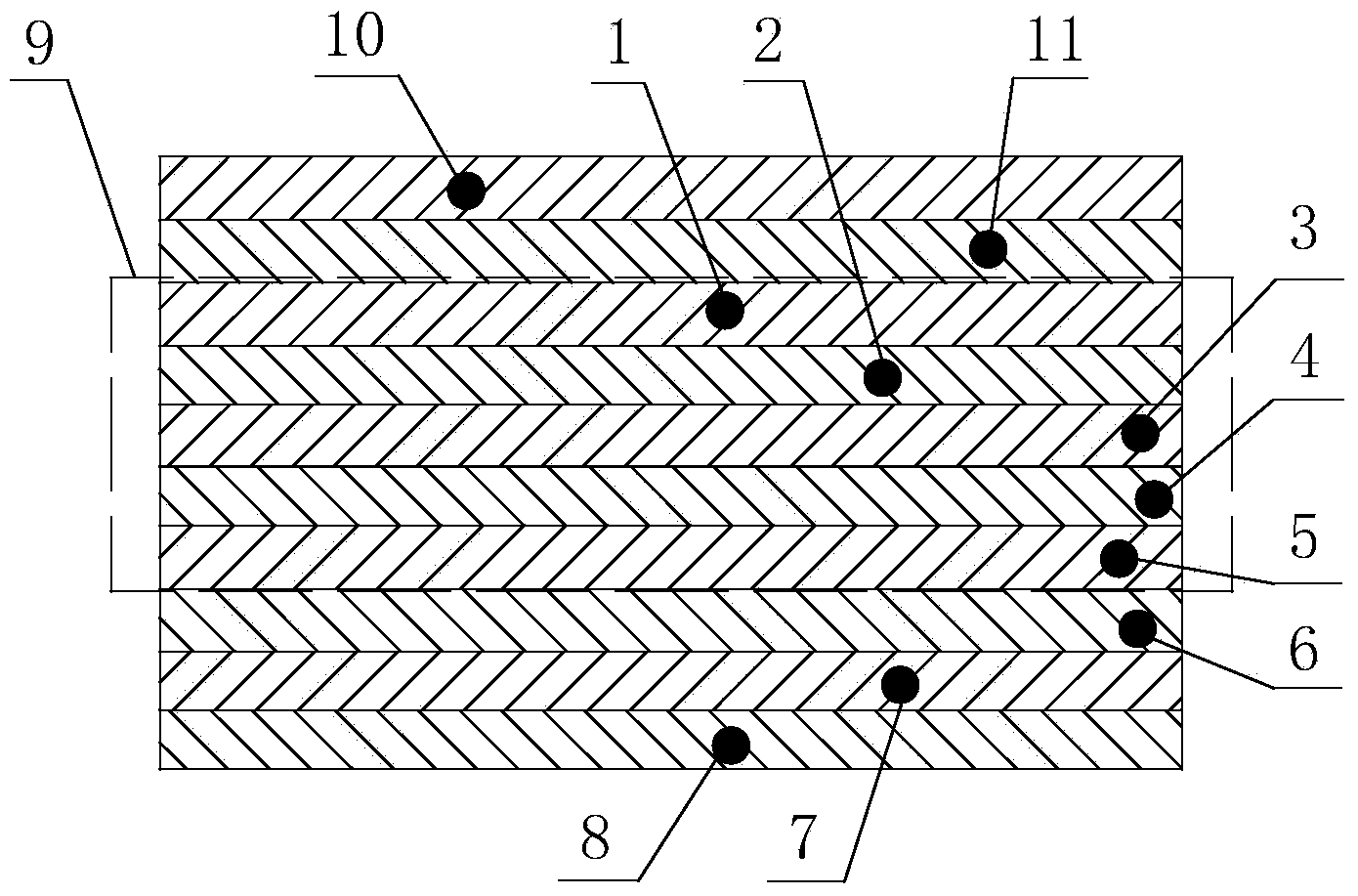

[0021] Such as figure 1 As shown, the anti-fogging three-dimensional cold lamination composite paper is composed of a varnish layer 10, an antifogging agent layer 11, a three-dimensional cold lamination film layer 9, an adhesive layer 6, a paper layer 7 and a back glue layer 8. The varnish layer 10, The anti-fogging agent layer 11, the three-dimensional cold lamination film layer 9, the adhesive layer 6, the paper layer 7, and the back-coated adhesive layer 8 are sequentially combined into one body.

[0022] The three-dimensional cold lamination film layer 9 is composed of a glue layer 1, an aluminum layer 2, a molded information layer 3, a coating layer 4 and a biaxially oriented polypropylene film 5, and the glue layer 1, the aluminum layer 2, and a molded information layer 3. The coating layer 4 and the biaxially stretched polypropylene film 5 are sequentially combined into one body.

[0023] The material of antifogging agent layer 11 is antifogging agent, and consumption ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com