Method for preparing inorganic non-metallic material quantum dots by electrochemical ion impact and application thereof

An inorganic non-metallic and quantum dot technology, which is applied in the fields of materials science and electrochemistry, can solve the problems of uneven size of quantum dots, difficulty in expanding production, and harsh experimental operations, so as to achieve controllable shape, easy operation, and low cost. cheap effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0037] In some embodiments, the preparation method of the working electrode includes: uniformly mixing the powdery active material with a binder and a conductive agent in an organic solvent, then coating it on a conductive carrier, and then drying it to obtain the the working electrode.

[0038] Further, the conductive carrier includes metal foil, for example, preferably copper foil, and is not limited thereto.

[0039] Further, the conductive agent includes carbon black or acetylene black, but is not limited thereto.

[0040] Further, the binder includes polyvinylidene fluoride (PVDF), and is not limited thereto.

[0041] In some more specific implementation cases, the preparation method of the working electrode comprises: at least homogenizing powdered active material raw materials, acetylene black, polyvinylidene fluoride (PVDF), etc. in N-methylpyrrolidone (NMP) 8h, after the homogenization is finished, spread it evenly on the copper foil and dry it overnight.

[0042] Pr...

Embodiment 1

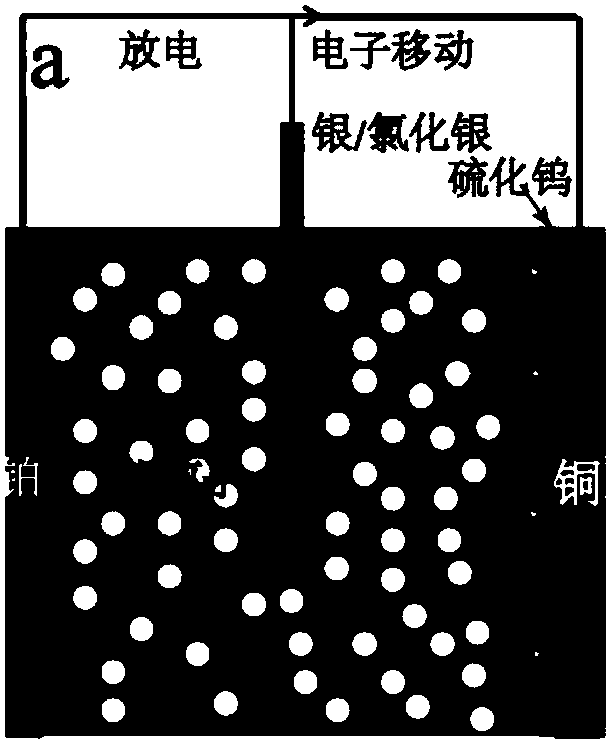

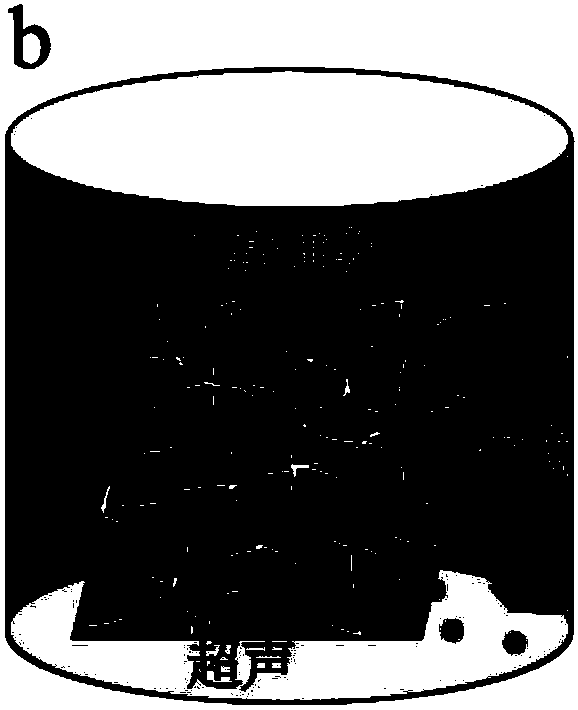

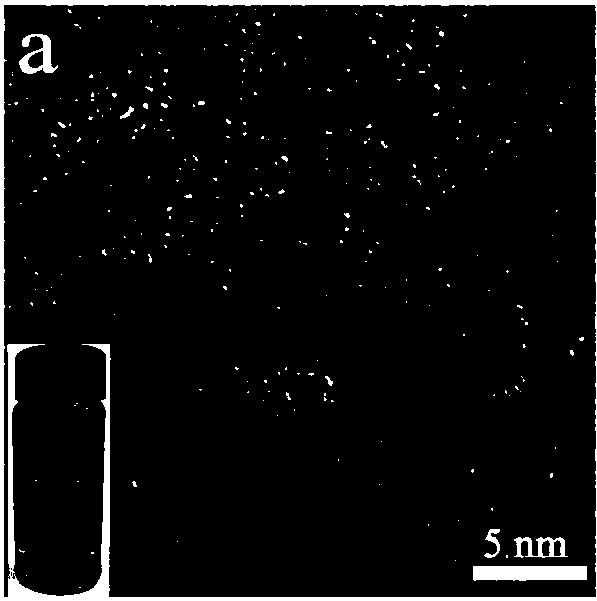

[0093] Embodiment 1: 200mgWS 2 Disperse with 25mg acetylene black, 25mg polyvinylidene fluoride (PVDF) in 2mL N-methylpyrrolidone and homogenize for more than 8 hours, then evenly coat the active substance on a 9cm×3cm×3cm copper foil, the active substance accounts for The area is 3cm×3cm, and then the electrode is dried overnight in a vacuum oven at 100°C, and then the copper foil is used as the working electrode, the Ag / AgCl is used as the reference electrode, and the Pt electrode is used as the counter electrode, and the electrolyte is 1mol / L Al(ClO 4 ) 3 9H 2 Propylene carbonate (PC) solution of O, the working electrode is discharged by chronopotentiometry (the principle can be referred to Figure 1a-Figure 1b As shown, the discharge treatment voltage window is about 0-0.35V, and the discharge current can be 0.11mA / cm 2 、0.50mA / cm 2 、1.0mA / cm 2 、1.11mA / cm 2 ), and then add the electrochemically treated active material into oleic acid for ultrasonic (ultrasonic power ...

Embodiment 2

[0095] Embodiment 2: 200mg MoS 2 Disperse with 25mg acetylene black, 25mg polyvinylidene fluoride (PVDF) in 2mL N-methylpyrrolidone and homogenize for more than 8 hours, then evenly coat the active substance on a 9cm×3cm×3cm copper foil, the active substance accounts for The area is 3cm×3cm, and then the electrode is dried overnight in a vacuum oven at 100°C, and then the copper foil is used as the working electrode, the Ag / AgCl is used as the reference electrode, and the Pt electrode is used as the counter electrode, and the electrolyte is 1mol / L Al(ClO 4 ) 3 .9H 2 Propylene carbonate (PC) solution of O, discharge treatment on the working electrode by chronopotentiometric method (the discharge treatment voltage window is about 0-0.35V, and the discharge current can be 0.056mA / cm 2 、0.10mA / cm 2 、0.25mA / cm 2 、0.56mA / cm 2 ), then add salicylic acid to the electrochemically treated active material (ultrasonic power is 100W, ultrasonic time is 15min), and finally wash with a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com