Tubular tape sealing machine applying carrier roller

A belt conveyor and idler technology, applied in the direction of rollers, conveyors, conveyor objects, etc., can solve the problems of acid and alkali corrosion resistance, easy oxidation and corrosion cost, etc., and achieves good rigidity and wear resistance, and is easy to manufacture and install. , The effect of reducing maintenance labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

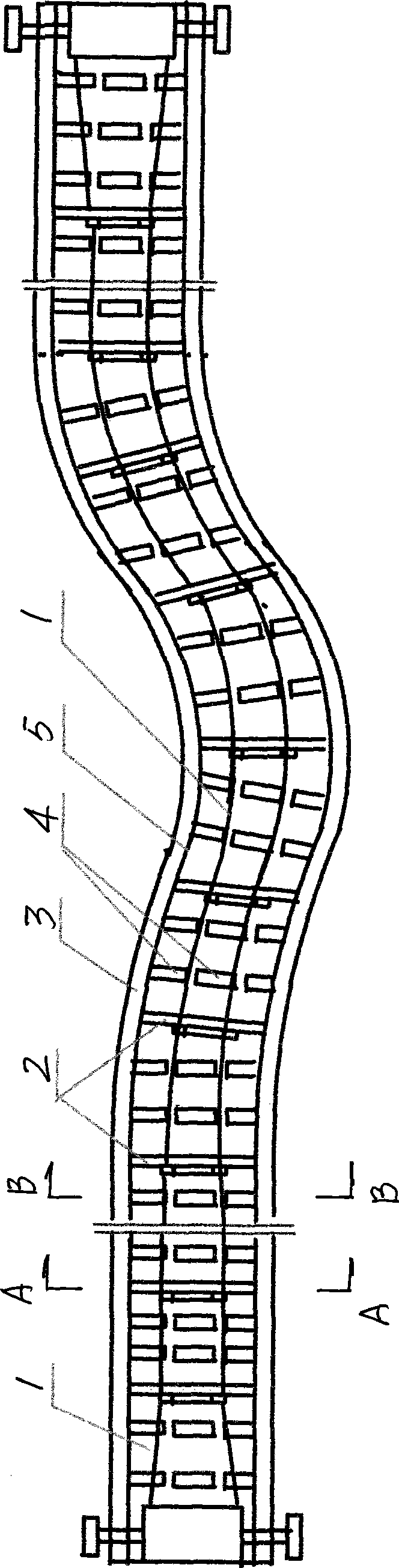

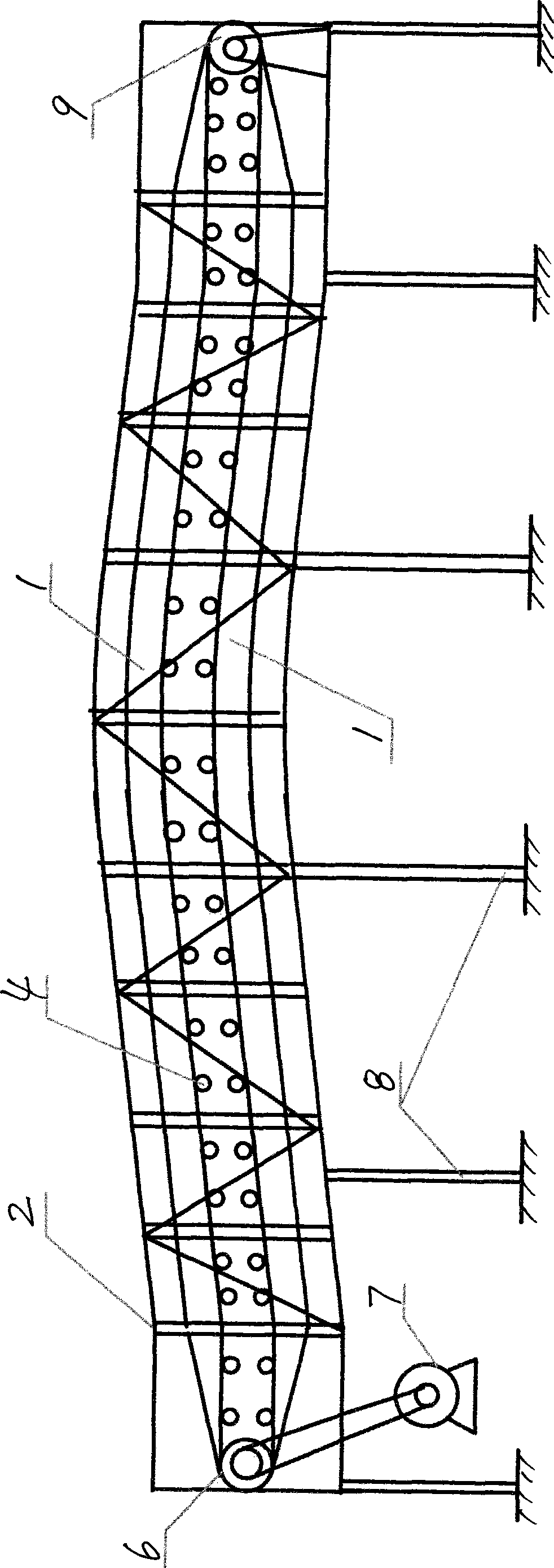

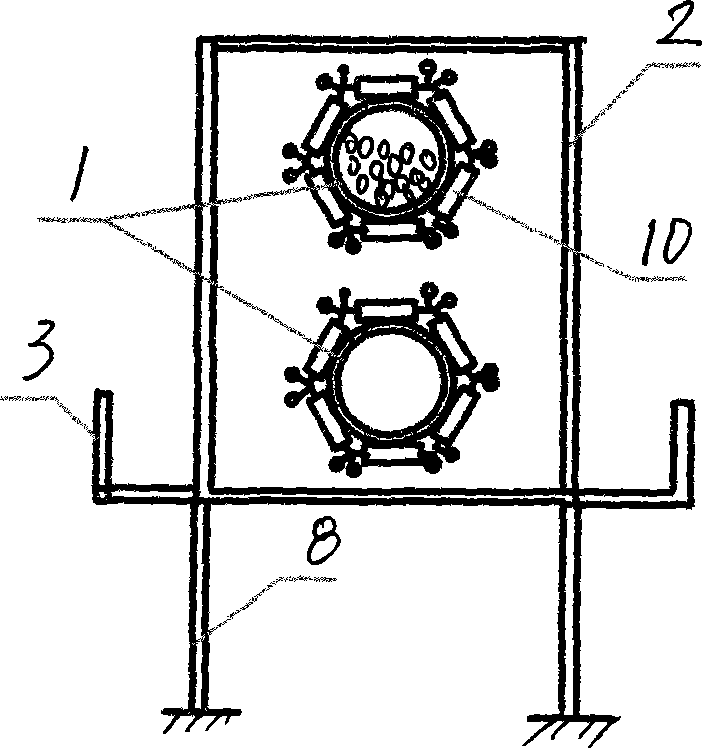

[0012] exist figure 1 , figure 2 , image 3 with Figure 4 Among them, the ceramic roller tubular belt conveyor is a conveyor belt system composed of a receiving section, a discharging section, a straight section, a horizontal curved section, a vertical curved section and a three-dimensional curved section. The conveyor belt system is all made of steel The truss structure is formed. The total length of the conveyor belt system can be determined according to the needs of the project. The maximum length can reach more than 2000 meters, the maximum slope angle can reach 30°, the horizontal and vertical turning radius is not less than 300 times the pipe diameter, and the horizontal turning The angle is less than 90°, the horizontal curved section includes a straight section and a curved section, and the conveyor belt system includes a pillar 8, a frame 5, a frame 2, a profile 3, a belt 1, a driving roller 6, a motor 7, and a driven roller 9 And support idler 4 and forming idle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com