Artificial fish reef materials and method for preparing fish reef thereof

A technology of artificial fish reefs and fish reefs, applied in fish farming, application, climate change adaptation, etc., can solve problems such as unfavorable algae attachment and growth, reduced life of artificial fish reefs, concrete expansion and deterioration, etc., to shorten installation and recycling Time, reduction of transportation and labor costs, effect of enhanced adsorption performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

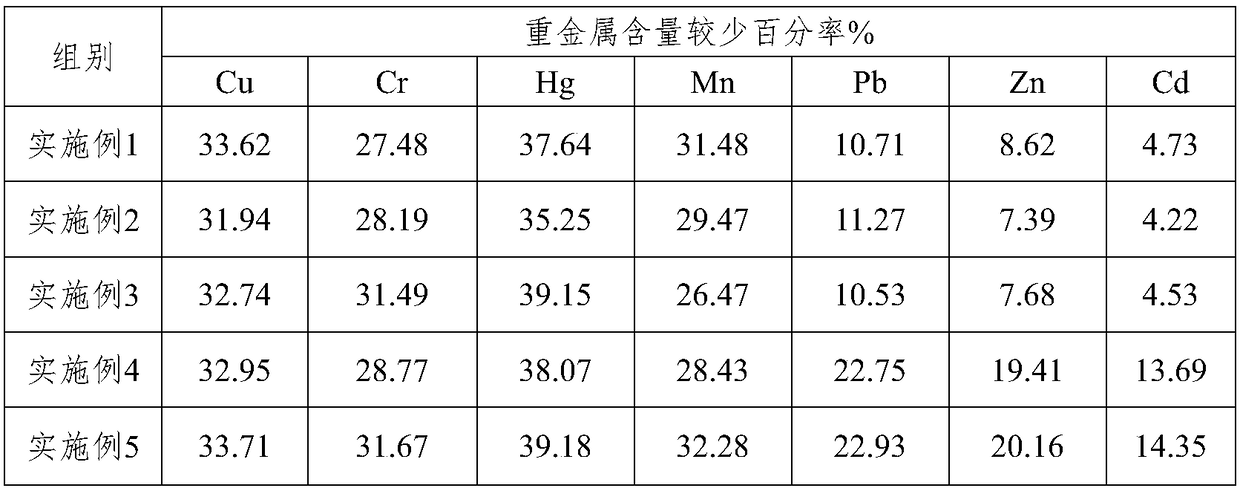

Embodiment 1

[0026] An artificial fish reef material, comprising the following raw materials in parts by weight: polyethylene 80kg, cellulose-thiosemicarbazide 35kg, bentonite 20kg, illite powder 35kg, coupling agent KH-5503kg, vinyl triperoxy tert-butyl silane 1kg .

[0027] The method for preparing a fish reef from the above-mentioned artificial fish reef material comprises the following steps:

[0028] (1) After mixing illite powder and bentonite, place it at 400°C for 20 minutes. When the temperature drops below 100°C, add coupling agent KH-550, stir at 200r / min for 3 minutes, and cool to room temperature. get premix;

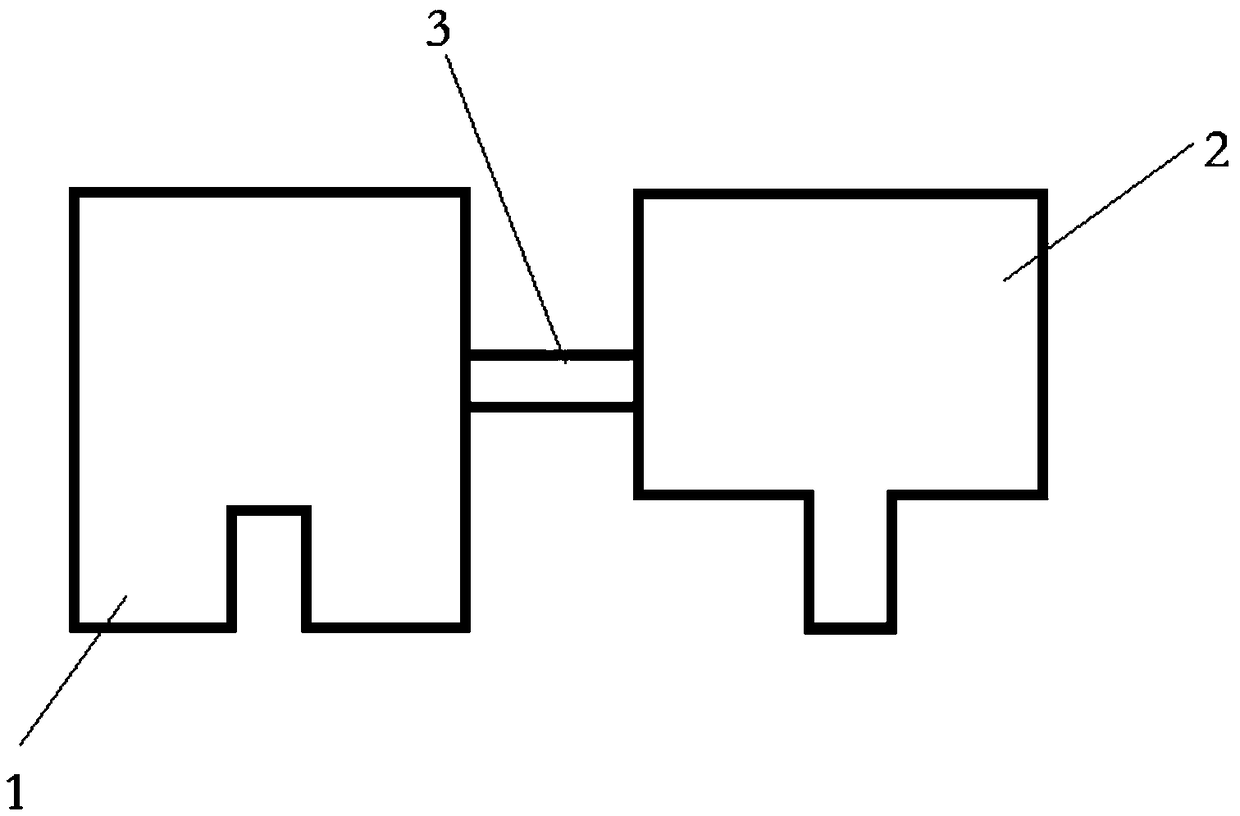

[0029] (2) Mix polyethylene, cellulose-thiosemicarbazide, and vinyl triperoxy-tert-butylsilane, stir at a constant temperature of 50°C for 20 minutes, cool to room temperature, mix with the above premix, and mix at 200r / min Stir for 3 minutes, and pour the obtained mixture into the fish reef mold to form it.

[0030] The particle diameters of the illite powder and be...

Embodiment 2

[0035] An artificial fish reef material, comprising the following raw materials in parts by weight: polyethylene 120kg, cellulose-thiosemicarbazide 55kg, bentonite 30kg, illite powder 55kg, coupling agent KH-5505kg, vinyl triperoxy tert-butyl silane 2kg .

[0036] The method for preparing a fish reef from the above-mentioned artificial fish reef material comprises the following steps:

[0037] (1) After mixing illite powder and bentonite, place it at 600°C for 30 minutes. When the temperature drops below 100°C, add coupling agent KH-550, stir at 300r / min for 5 minutes, and cool to room temperature. get premix;

[0038] (2) Mix polyethylene, cellulose-thiosemicarbazide, and vinyl triperoxy-tert-butylsilane, stir at a constant temperature of 60°C for 30 minutes, cool to room temperature, mix with the above premix, and mix at 300r / min Stir for 5 minutes, and pour the obtained mixture into the fish reef mold to form it.

[0039] The particle diameters of the illite powder and b...

Embodiment 3

[0042]An artificial fish reef material, comprising the following raw materials in parts by weight: polyethylene 90kg, cellulose-thiosemicarbazide 45kg, bentonite 22kg, illite powder 38kg, coupling agent KH-5503kg, vinyl triperoxy tert-butyl silane 1.5 kg.

[0043] The method for preparing a fish reef from the above-mentioned artificial fish reef material comprises the following steps:

[0044] (1) After mixing illite powder and bentonite, place it at 450°C for 20 minutes. When the temperature drops below 100°C, add coupling agent KH-550, stir at 300r / min for 5 minutes, and cool to room temperature. get premix;

[0045] (2) Mix polyethylene, cellulose-thiosemicarbazide, and vinyl triperoxy-tert-butylsilane, stir at a constant temperature of 55°C for 30 minutes, cool to room temperature, mix with the above premix, and mix at 240r / min Stir for 5 minutes, and pour the obtained mixture into the fish reef mold to form it.

[0046] The particle diameters of the illite powder and b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com