Steel bar lap joint structure containing FRP constraint ring

A technology of lap connection and confinement ring, which is applied to the connection of steel bars in concrete structures and the field of steel bar lap connection structures, can solve problems such as high requirements for construction and installation accuracy, impact on production efficiency, weakened energy dissipation capacity of connection position deformation, etc., to achieve Low requirements for construction and installation accuracy, reliable and stable connection performance, and easy to guarantee construction quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

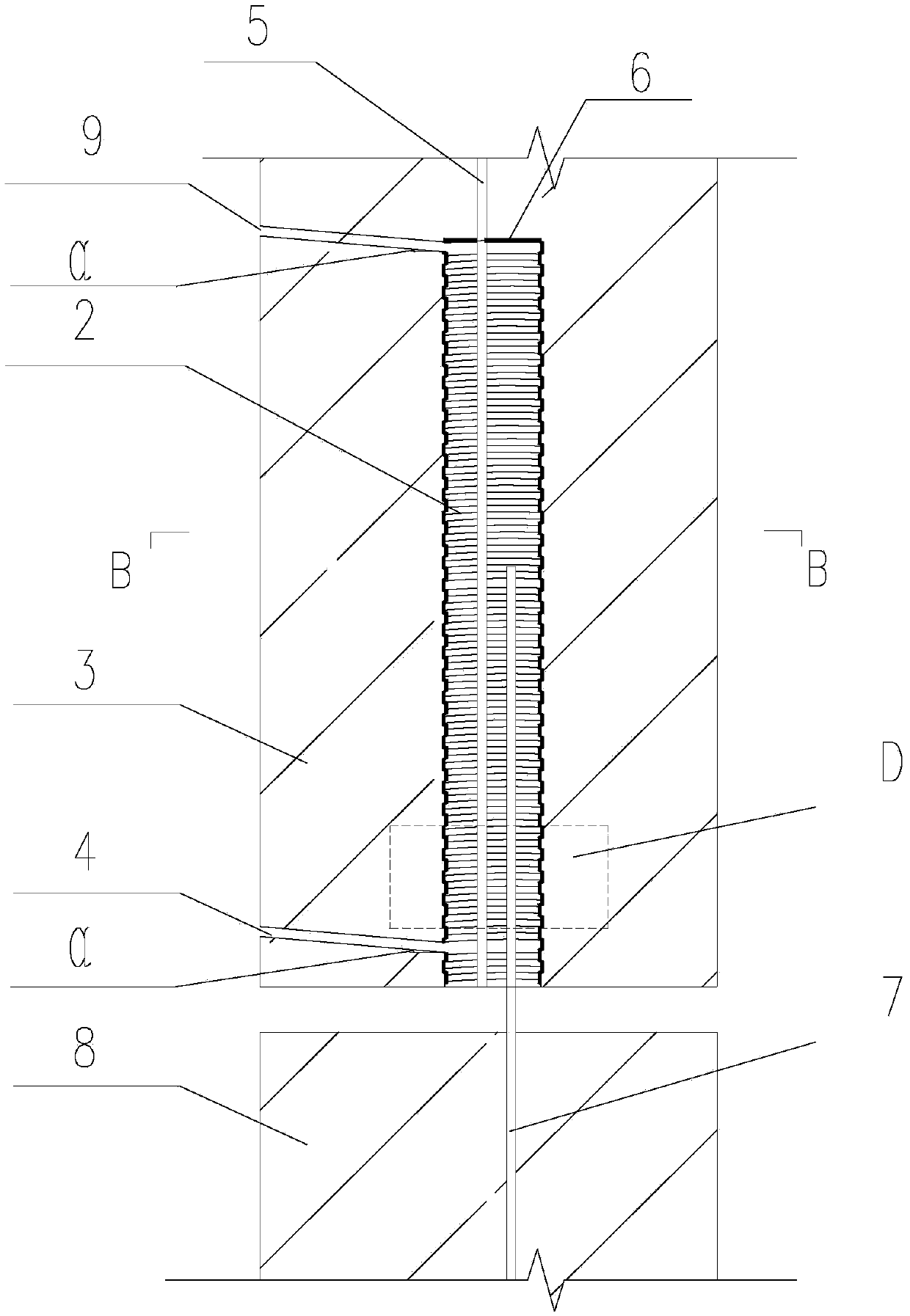

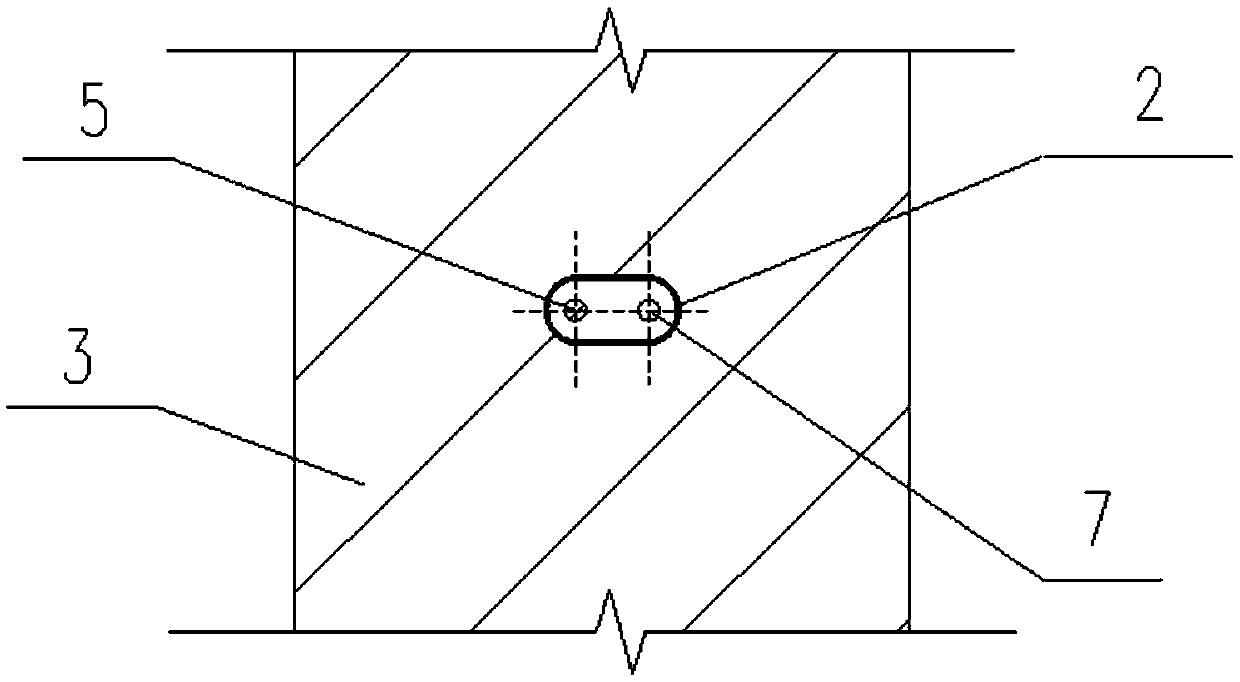

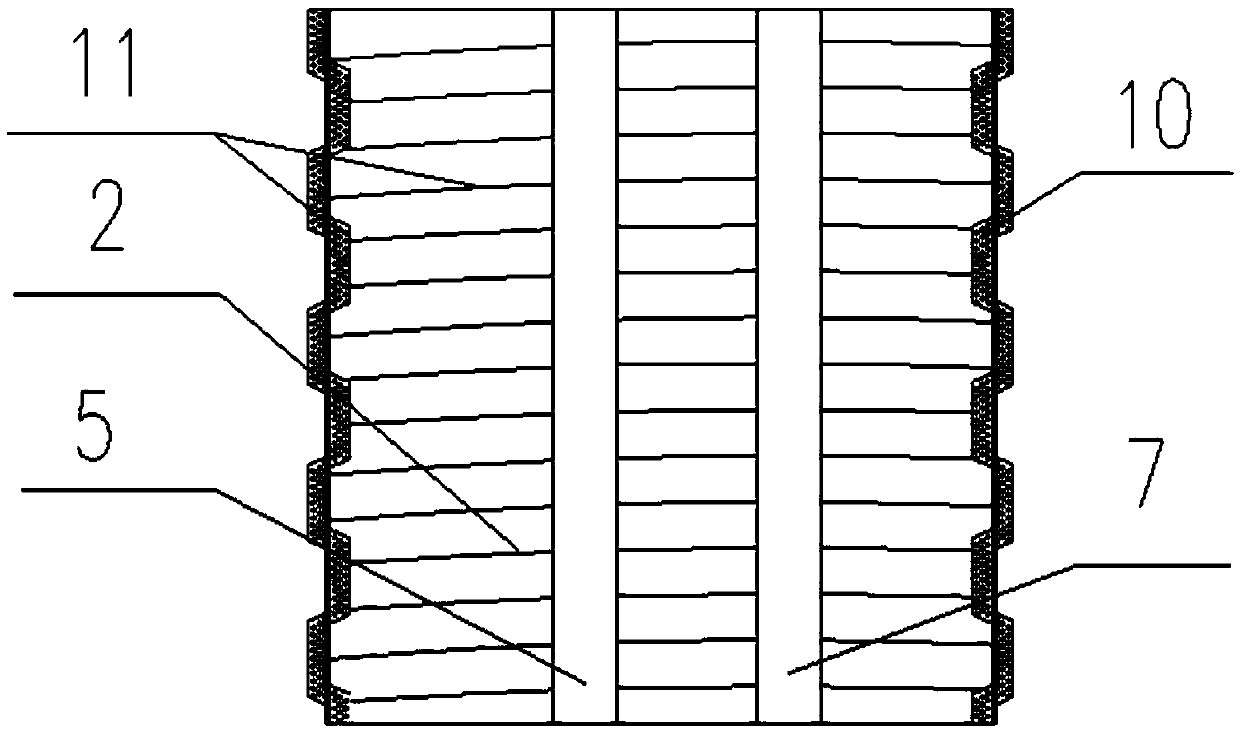

[0030] Example: such as figure 1 , figure 2 As shown, the present invention includes an upper prefabricated component 3, a lower prefabricated component 8, a FRP restraint ring 2, a pre-embedded steel bar 5 and an outstretched connecting steel bar 7, and an FRP restraint ring 2 is arranged inside the lower end of the upper prefabricated component 3, and the FRP restraint ring 2 There is a grouting hole 4 at the lower end, a grouting hole 9 at the upper end, and a sealing elastic rubber sealing ring 6 with a round hole at the top of the FRP confinement ring 2 to prevent the entry of concrete mortar, etc.; The steel bar 5 extends into the FRP confinement ring 2 through the round hole of the sealing ring 6, and the externally extending connecting steel bar 7 in the lower prefabricated component 8 protrudes into the FRP confinement ring 2 to form an overlap with the pre-embedded steel bar 5 in the upper prefabricated component 3 For connection, the expansion grouting material is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com