High temperature gradient low melt flow electromagnetic induction heating device

An induction heating device and flowing electromagnetic technology, applied in the field of materials, can solve the problems of unfavorable directional tissue growth, slow heating and cooling rates, and low temperature gradients

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

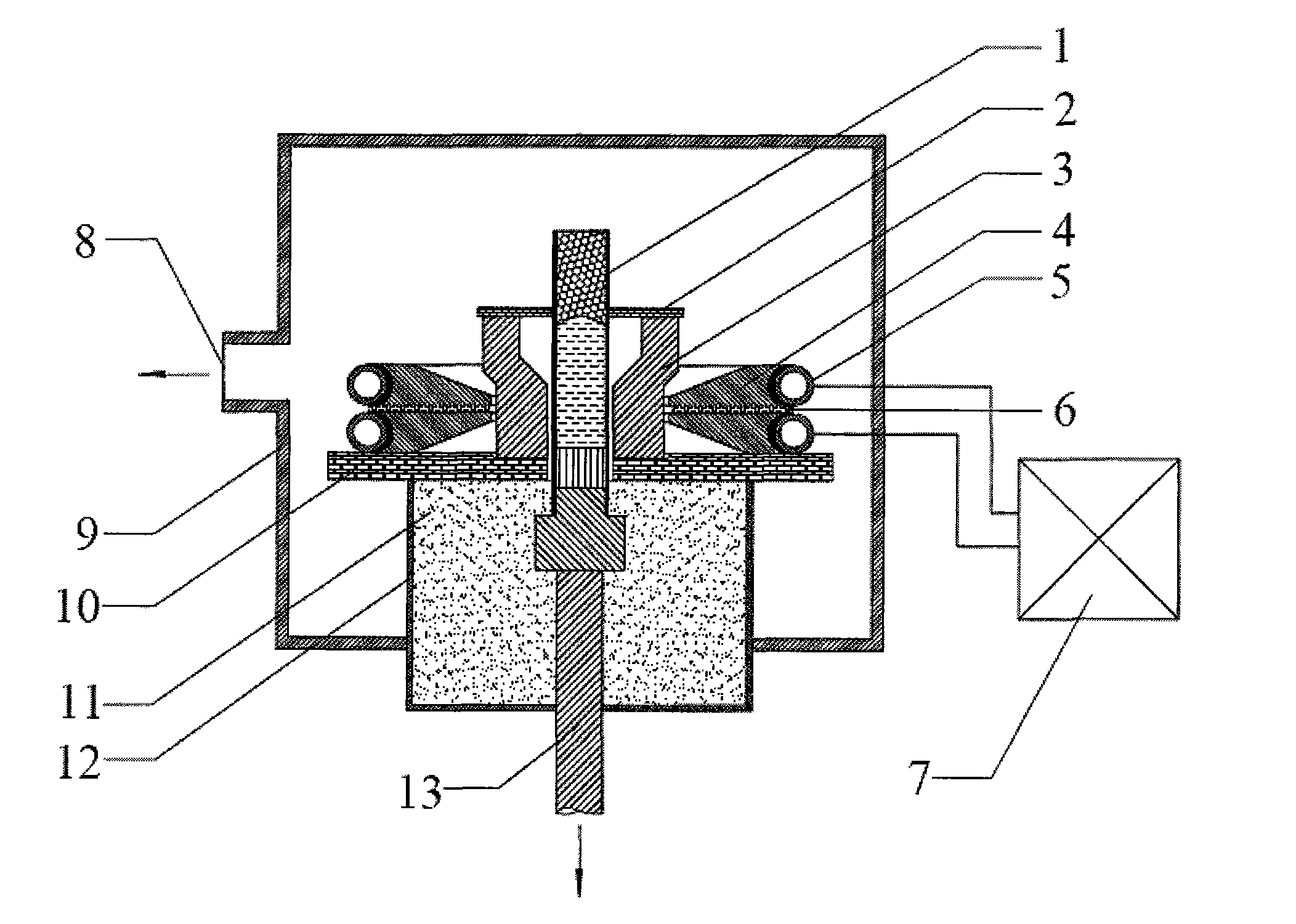

[0023] This embodiment includes a graphite induction heating device, a ceramic crucible 1 , a water-cooled crystallizer 12 , a vacuum chamber 9 , a vacuum extraction system 8 , a pull-down system 13 and a high-frequency induction heating power supply 7 . The frequency of the high-frequency induction heating power supply 7 is 200KHZ, and the outer diameter of the ceramic crucible 1 is 9mm.

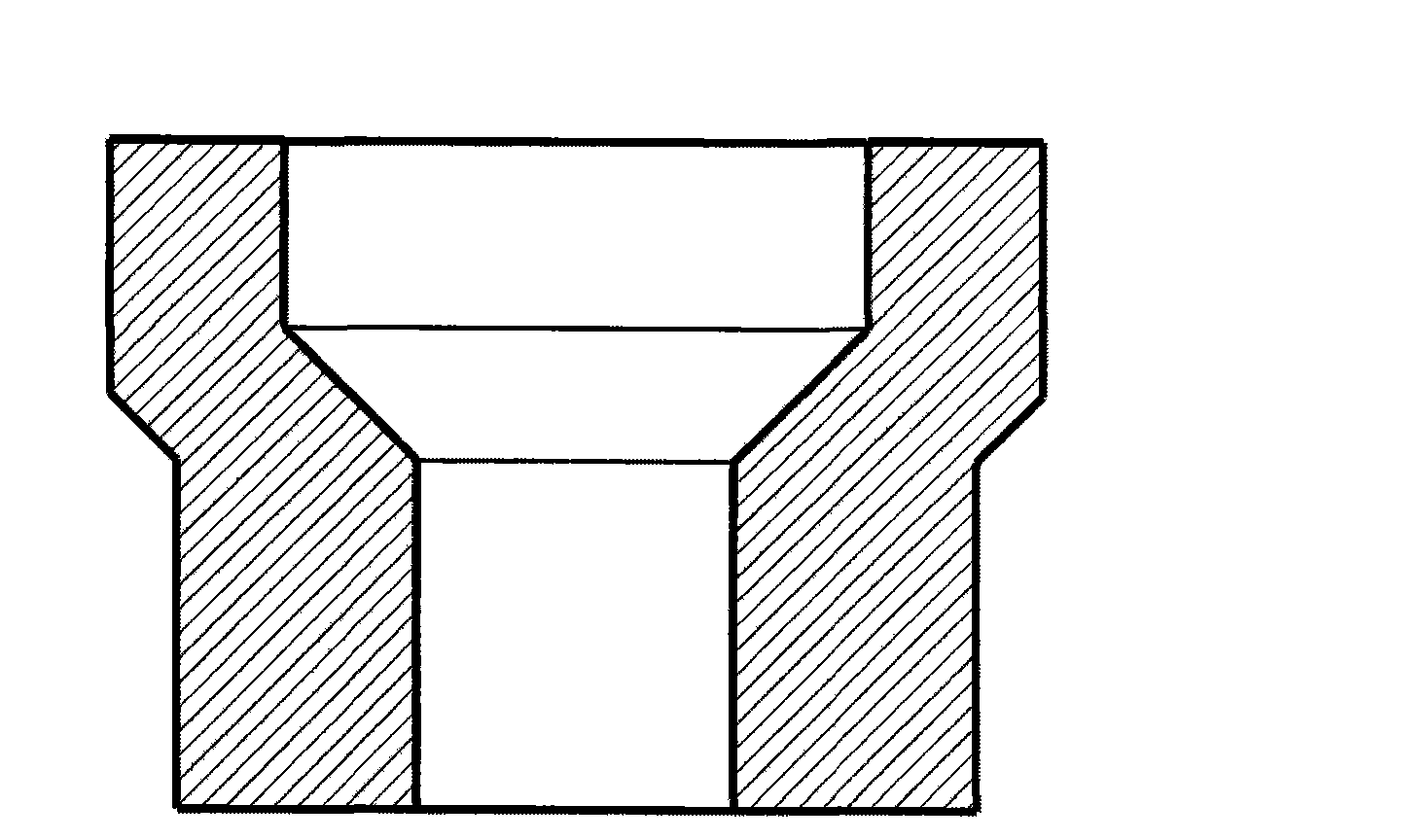

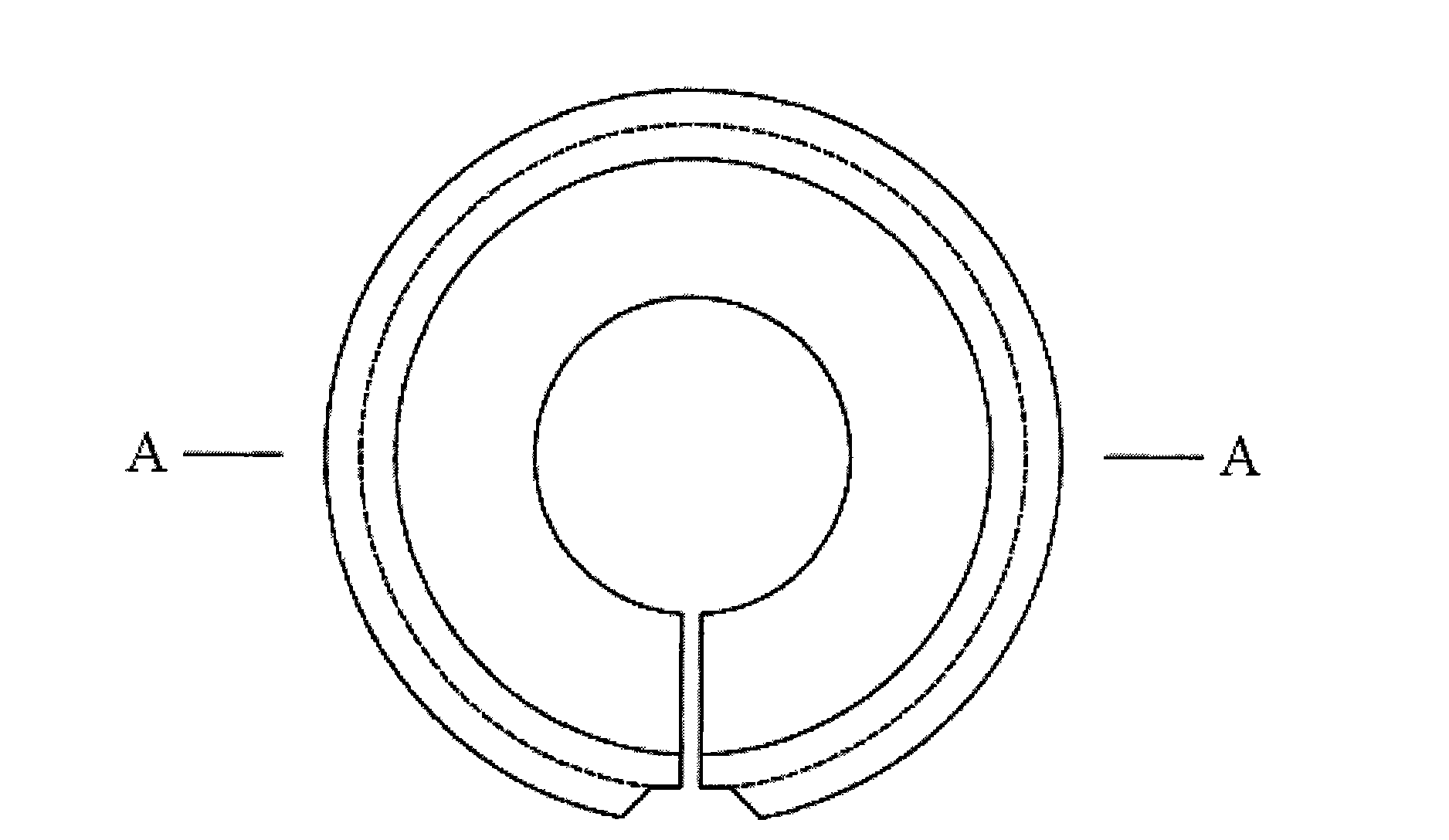

[0024] as attached Figure 6 As shown in , the graphite induction heating device is composed of a coil, a high-frequency inductor 4, a graphite heating body 3 and an upper heat insulation board 2. The coil has two turns and is made of a 6mm hollow copper tube, which is set in the groove on the outer surface of the high-frequency inductor, and is seamlessly connected with the high-frequency inductor through the welding structure 14 .

[0025] The ring-shaped high-frequency inductor 4 is made of red copper and has two turns, and its outer peripheral surface has an arc-shaped groove with a di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com