Optical fiber preform manufacturing method

An optical fiber preform and a manufacturing method technology, which are applied to manufacturing tools, glass manufacturing equipment, glass deposition furnaces, etc., can solve the problem that the shape of the end face of the powder preform has a large deviation from the set shape and is not suitable for the control parameters of the outer diameter of the powder preform. , reduce the control accuracy and other problems, to achieve the effect of high precision and anti-interference ability, reduce the mutual interference of flames, and improve the control effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

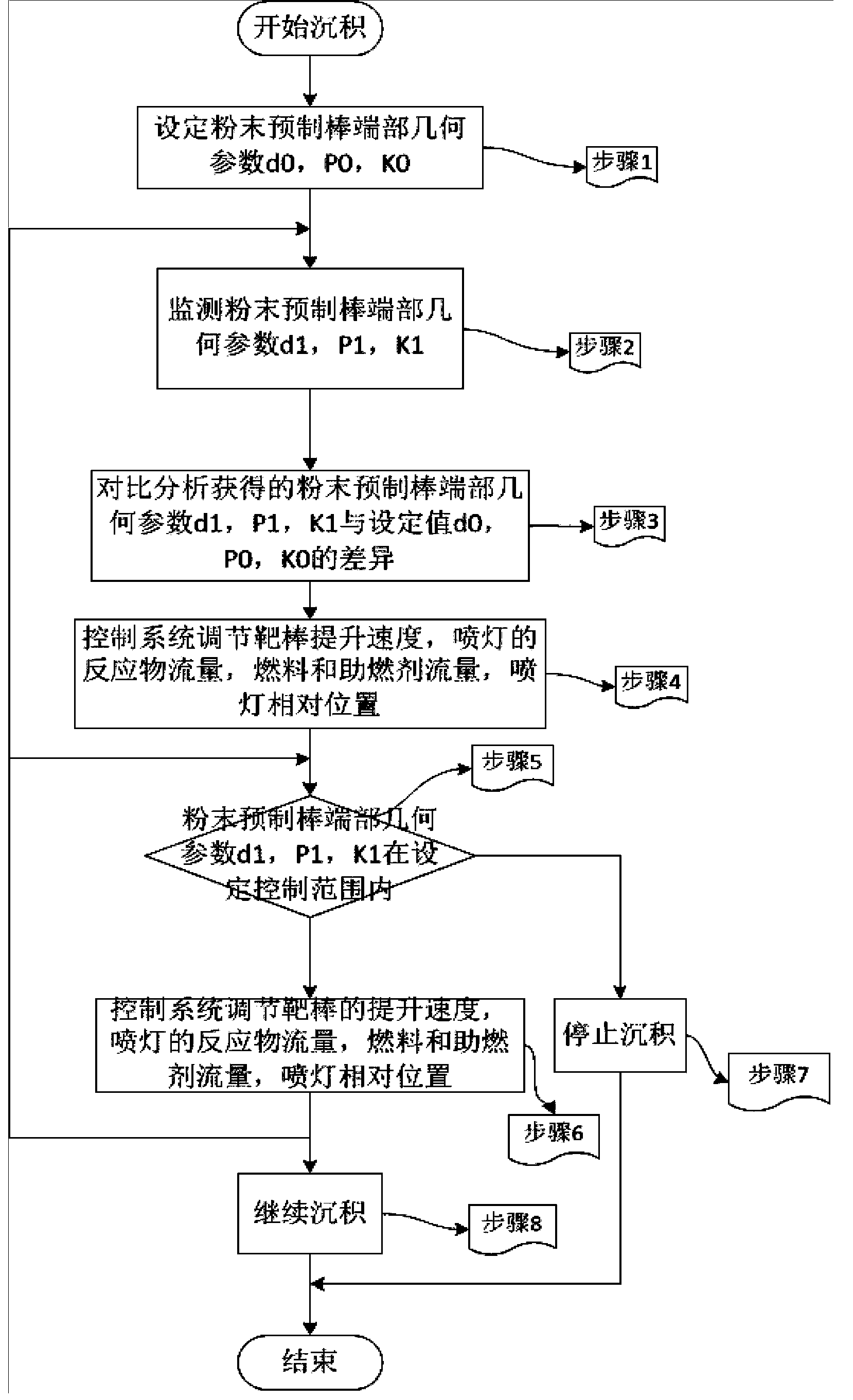

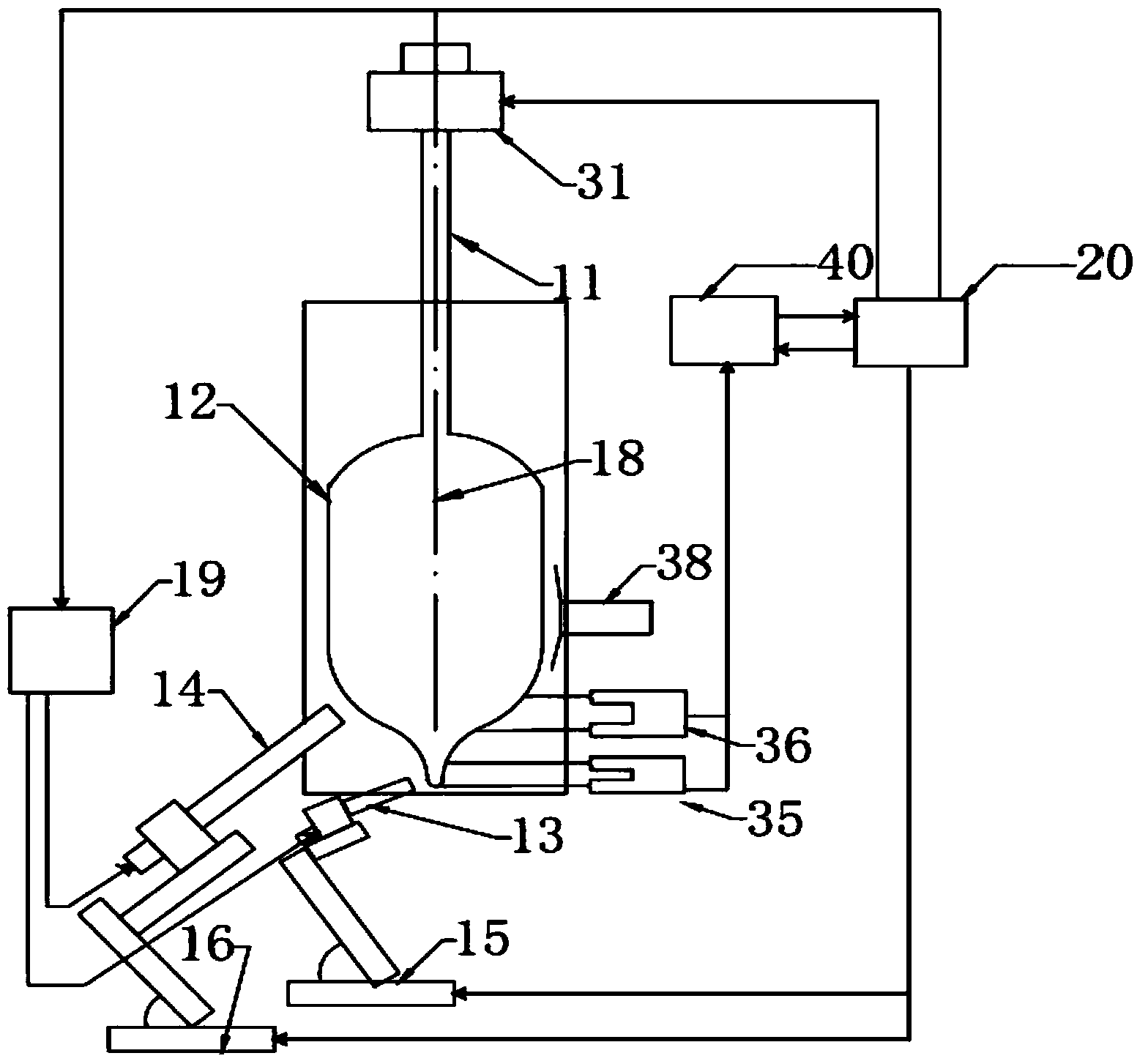

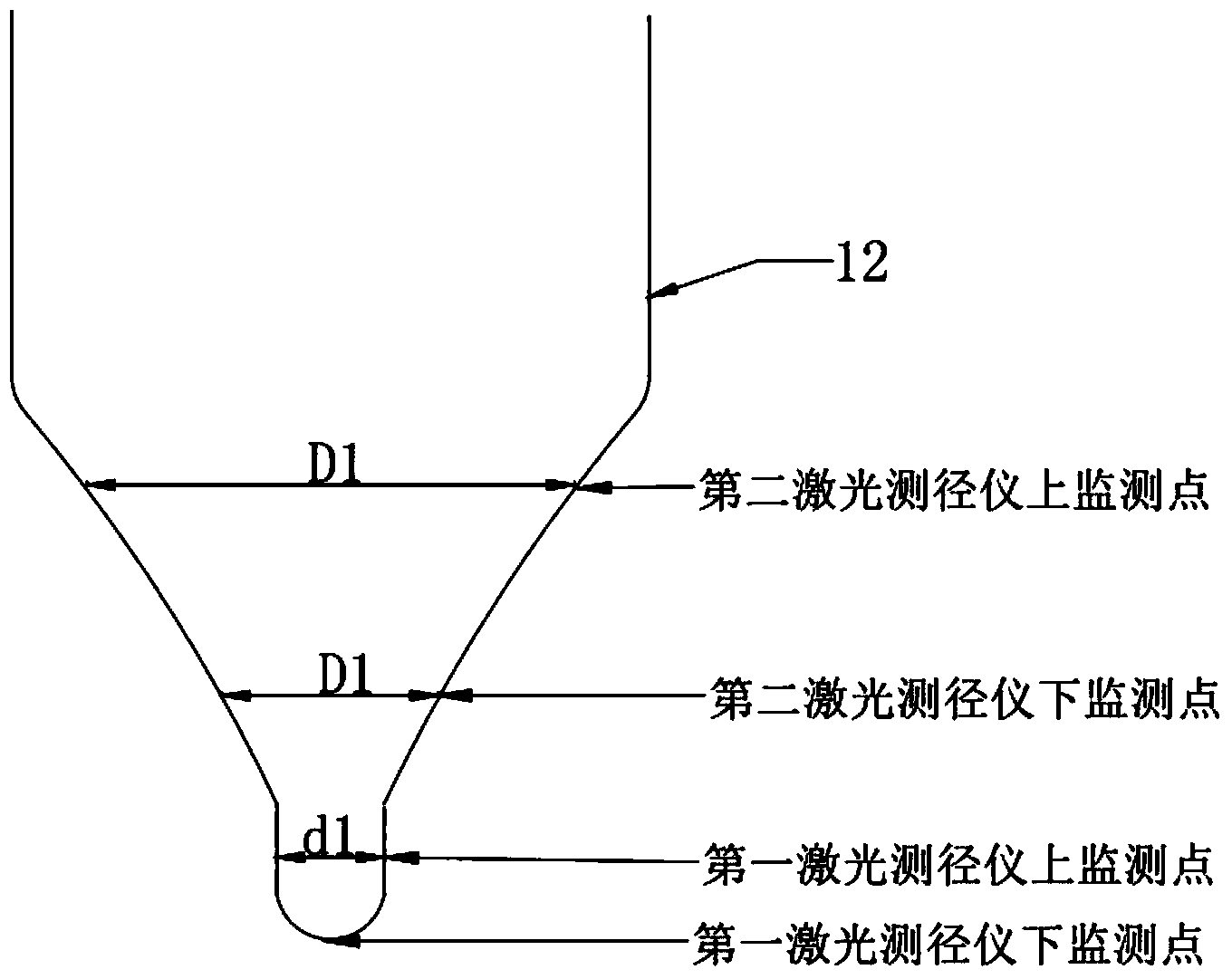

[0065] a. Example 1: Traditional method: In the VAD method, a high-purity quartz target rod with a diameter of 35mm is used, and two torches are used to deposit the core layer and the cladding powder layer respectively, where the core layer is SiO 2 With Geo 2 Mixture, cladding is SiO 2 Powder, the average density of powder preform is 0.28gram / cm 3 , The length of the uniform part of the outer diameter of the powder body is 1000mm; the median value P0 of the geometric parameter setting value of the top of the powder preform is 2.5, and the control range of P0 is 2-3; the geometric parameters of the top of the powder preform are measured in real time by the measurement system, and the measurement result is analyzed by the analysis system Perform analysis and calculation, where the measurement system is composed of a first laser diameter gauge and a second laser diameter gauge;

[0066] After the deposition, the powder preform is transferred to the conveying platform of the dehydrati...

Embodiment 2

[0069] c. Example 2: Traditional method: In the VAD method, a high-purity quartz target rod with a diameter of 30mm is used, and two torches are used to separately deposit the core layer and the cladding powder layer, where the core layer is SiO 2 With Geo 2 Mixture, cladding is SiO 2 Mixture with F, the average density of powder preform is 0.25gram / cm 3 , The length of the powder body is 1000mm; the d0 of the geometric parameter setting value of the top of the powder preform is 30mm, and the control range of d10 is 28mm-32mm; the geometric parameters of the top of the powder preform are measured in real time by the measurement system, and the analysis system analyzes the measurement results Calculation, where the measurement system consists of the first laser diameter gauge and the second laser diameter gauge;

[0070] After the deposition is completed, the powder preform is transferred to the conveying platform of the dehydration sintering furnace, the preform is extended into th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com