Continuous extracting method of microwave

A microwave and continuous technology, applied in the direction of solid solvent extraction, chemical/physical/physicochemical process of energy application, etc., can solve the problems of long production cycle, low production efficiency, high cost, etc., and achieve the goal of saving production time and improving extraction rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

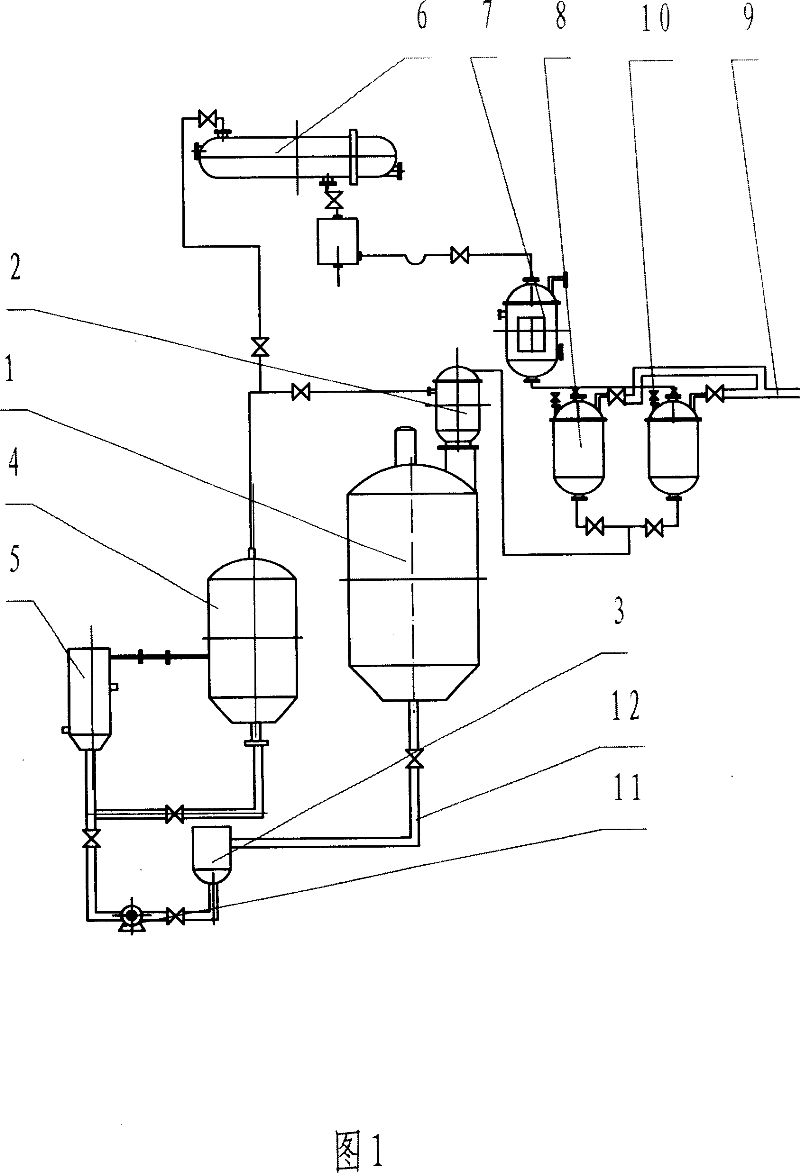

[0025] Embodiment 1: see Fig. 1, a kind of method for microwave continuous extraction, comprise microwave extraction equipment 1, be provided with the gas bubble catcher 2 that collects material to produce foam in heating process on microwave extraction equipment 1, and in microwave extraction The bottom of the equipment 1 is provided with a filter 3, and the delivery pipe 12 of the filter 3 is connected to the concentration heater 5, and the heated extract is transported to the concentration evaporation chamber 4 by the pressure difference and concentration difference, the cooling system 6, the oil-water separator 7 is to cool gaseous active ingredients and collect aromatic stem oils. The liquid storage tank 8, the vacuum system 9, and the liquid storage tank 8 are provided with an emptying valve 10.

[0026] The entire working process of the microwave continuous extraction process is as follows: pour the coarsely crushed, soaked and weighed materials into the microwave extrac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com