High-efficiency low-temperature wheat squeezing-cutting smashing milling process and milling device

A crushing mill and low-temperature technology, which is applied in the field of high-efficiency, low-temperature crushing and crushing wheat flour milling technology and equipment, can solve the problems of not achieving the effect of slag making, and achieve the effects of reducing power consumption, improving precision, and reducing investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

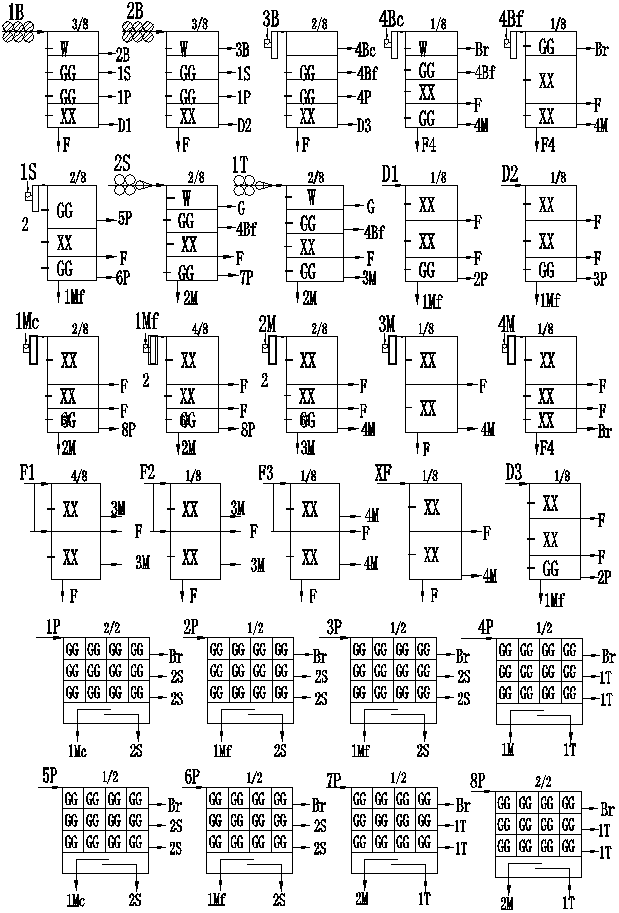

Image

Examples

Embodiment Construction

[0038] The invention provides a high-efficiency low-temperature squeezing and crushing wheat flour milling process, which includes a skin grinding process, a slag grinding process, a core grinding process, a tail grinding process and a powder cleaning process; the skin grinding process is provided with 4 skin mills, respectively 1 Leather, 2 skins, 3 skins and 4 skins; 1 skin and 2 skins are still lightly ground by toothed roller mill according to the existing technology; the slag grinding process is equipped with 2 slag mills, respectively 1 slag and 2 slag ; There are 4 heart grinding processes in the heart grinding process, which are 1 heart, 2 hearts, 3 hearts and 4 hearts;

[0039] The 3 skins adopt the high-speed extruding and cutting pulverizer disclosed in Chinese patent 201510793292.3, and the minimum gap between the rotor pin and the stator pin of the machine is reduced to 0.3 mm, and the high-speed extruding and cutting pulverizer is reduced by reducing the speed of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com