Infrared rapid heat-treatment cavity for semiconductor chip with movable heat baffle

A rapid heat treatment and thermal baffle technology, applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve problems such as inability to rapidly cool down, inability to achieve heating and cooling, and inability to accurately control temperature by the temperature control system, achieving high productivity , Wide heating temperature range, fast heating rate and cooling rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

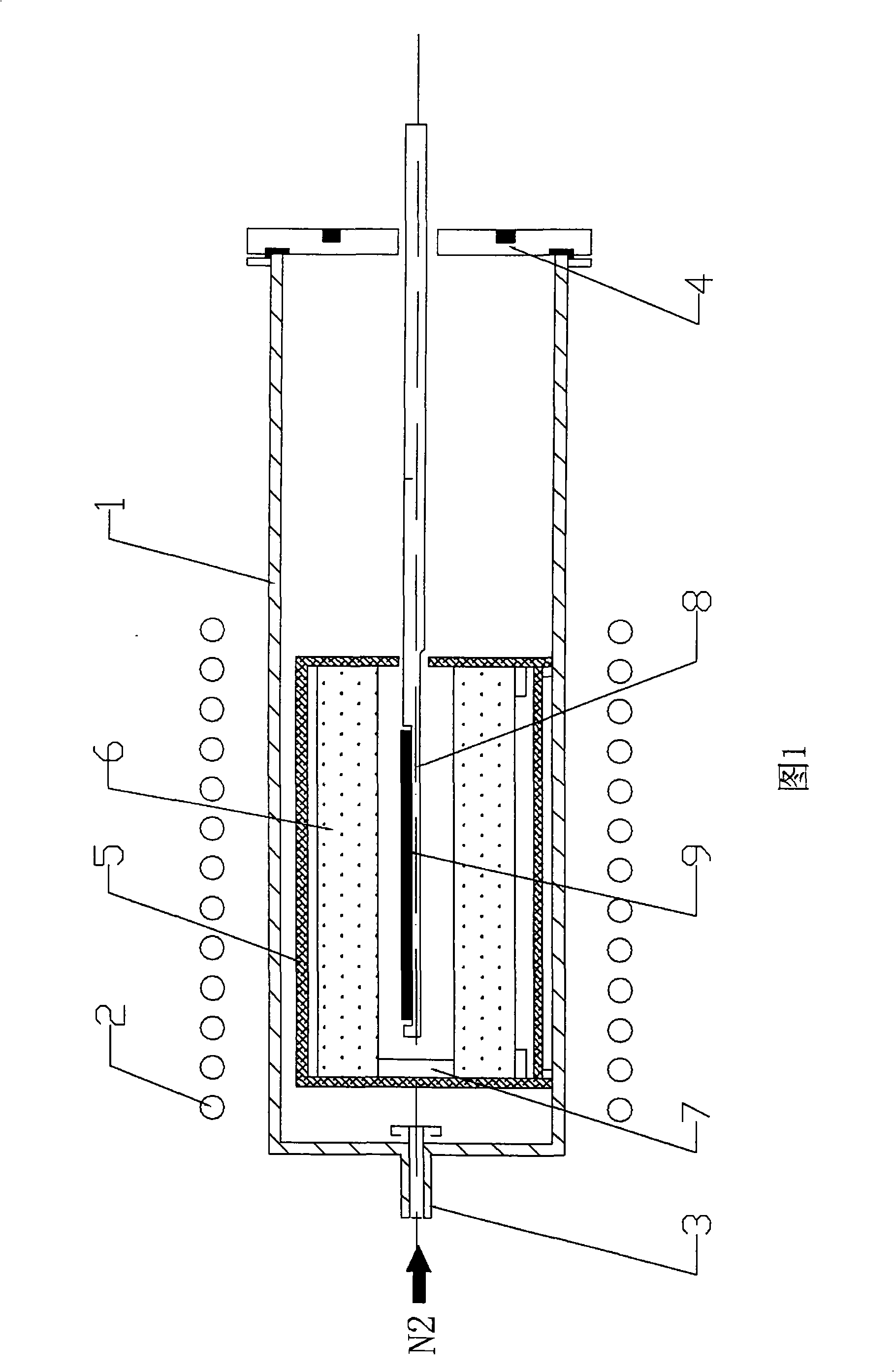

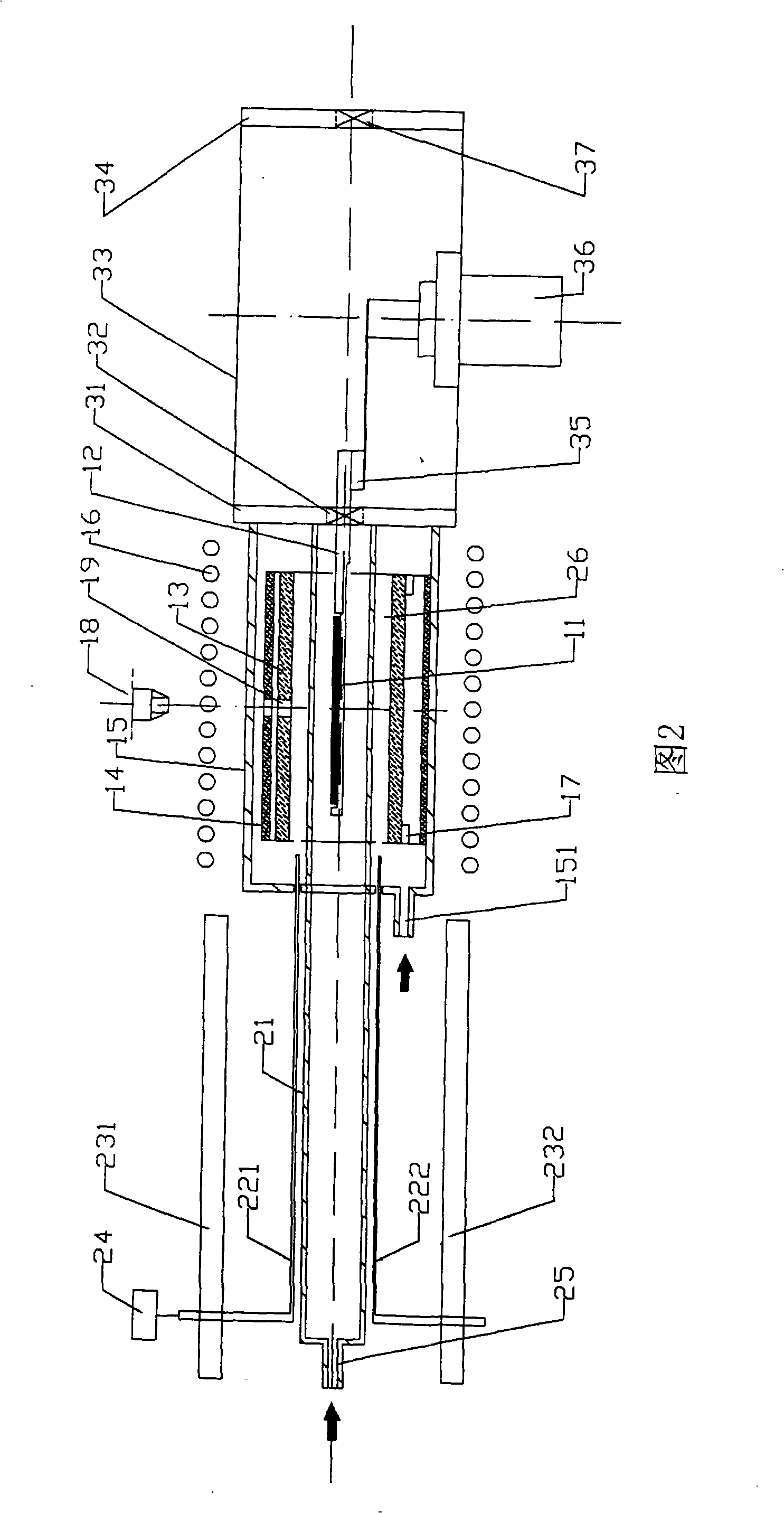

[0010] The infrared rapid heat treatment chamber with movable heat shield semiconductor chip proposed by the present invention is further described as follows in conjunction with the accompanying drawings and embodiments:

[0011] The overall structure of the embodiment of the infrared rapid heat treatment chamber with movable heat shield semiconductor wafers proposed by the present invention is shown in Figure 2, mainly comprising: a flat rectangle formed by a quartz inner chamber 21 and a quartz outer chamber 15 sleeved outside the inner chamber A double-layer quartz cavity, a flat rectangular graphite heating cavity 13 fixed between the quartz inner cavity and the outer cavity 15 (or adopt graphite material to outsource silicon carbide film, or adopt an infrared heating cavity made of high temperature resistant and oxidation resistant alloy material.) and Infrared reflection plate 14 is wound with radio frequency induction coil 16 outside the quartz outer cavity 15, the oute...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com