A method of regulating hydrogen content to improve the performance of titanium alloy prepared from titanium hydride powder

A technology of titanium hydride powder and hydrogen content, applied in the field of powder metallurgy, can solve the problems of demanding deformation speed and deformation temperature, unsatisfactory mechanical properties and processing properties, poor thermoplasticity of titanium alloys, etc., to improve the microstructure and mechanical properties. , shorten the production and alloy optimization processing process, improve the effect of plastic properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

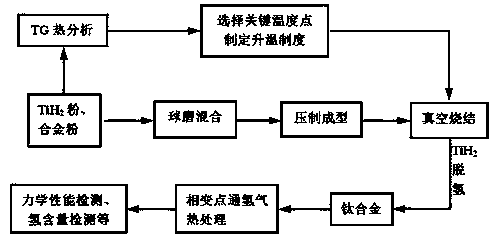

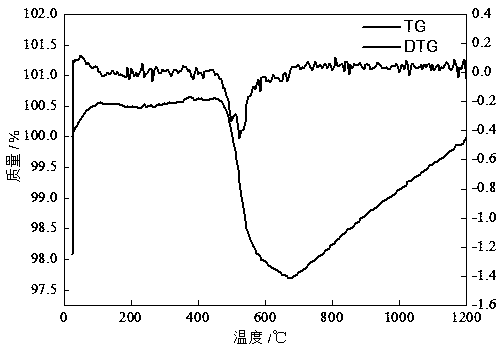

[0026] (1) For TiH 2 powder for TG / DSC thermal analysis (eg image 3 shown), to find out the TiH 2 The key dehydrogenation temperature points for decomposition are 400°C, 500°C, 600°C, and 750°C, and a corresponding sintering system is formulated. The heating rate is 5°C / min, and each key dehydrogenation temperature point is kept for 25 minutes respectively, reaching the final sintering temperature of 1400°C Keep warm for 4 hours.

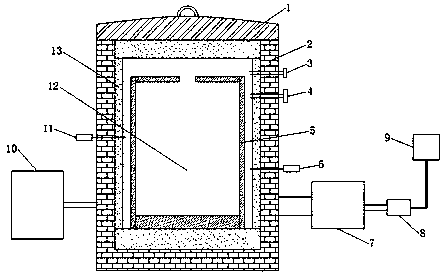

[0027] (2) TiH 2 Press the powder into the crucible after weighing, put the compact into the crucible, and place it in the center of the heating body 5, cover the furnace cover 1, check that the auxiliary equipment is normal, start the control cabinet, input the mass of the compact before sintering on the display terminal, and turn on the cooling system;

[0028] (3) Turn on the vacuum system 7 until the vacuum degree in the furnace reaches 1×10 -3 After Pa, set the sintering system set in 2 on the panel of the control cabinet, and turn on the...

Embodiment 2

[0033] (1) The TiH prepared according to the composition ratio of Ti-6Al-4V alloy 2 The powder and the Al-V alloy powder are ball milled in a planetary ball mill at a rotational speed of 250r / min for 2 hours until fully mixed.

[0034] (2) to TiH 2 and Al-V alloy mixed powder for TG / DSC thermal analysis (such as Figure 4 shown), to find out the TiH 2The key dehydrogenation temperature points for the decomposition of Al-V alloy mixed powder are 420°C, 500°C, 600°C, and 750°C, and the corresponding sintering system is formulated. The heating rate is 8°C / min, and each key dehydrogenation temperature point is kept for 30 minutes. , When it reaches the final sintering temperature of 1150 ° C, it is kept for 3 hours.

[0035] (3) Compress the mixed powder into a crucible after weighing, place the compact in the center of the heating body 5, and cover the furnace cover 1. After checking that the auxiliary equipment is normal, start the control cabinet and input the pressure on th...

Embodiment 3

[0041] (1) TiH prepared according to the ratio of Ti-13Nb-13Zr alloy composition 2 powder, Nb powder and ZrH 2 Put it into a planetary ball mill for ball milling at a speed of 300r / min, and mill for 3 hours until fully mixed.

[0042] (2) to TiH 2 , Nb and ZrH 2 TG / DSC thermal analysis of alloy mixed powder to find out TiH 2 , Nb and ZrH 2 The key dehydrogenation temperature points for the decomposition of alloy mixed powder are 400°C, 500°C, 600°C, 750°C, and 800°C, and the corresponding sintering system is formulated. The heating rate is 10°C / min, and each key dehydrogenation temperature point is kept for 40 minutes respectively. When it reaches the final sintering temperature of 1800°C, it is kept for 2 hours.

[0043] (3) Compress the mixed powder into a crucible after weighing, place the compact in the center of the heating body 5, and cover the furnace cover 1. After checking that the auxiliary equipment is normal, start the control cabinet and input the pressure on...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com