A temperature control device that directly heats the calibrated vacuum gauge in the vacuum chamber

A technology of temperature control device and vacuum gauge, applied in the direction of temperature control, non-electric variable control, control/regulation system, etc., can solve the problems of high heating power consumption, poor temperature uniformity and stability of vacuum chamber, etc., to improve accuracy , High temperature uniformity and stability, the effect of ensuring thermal uniformity and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

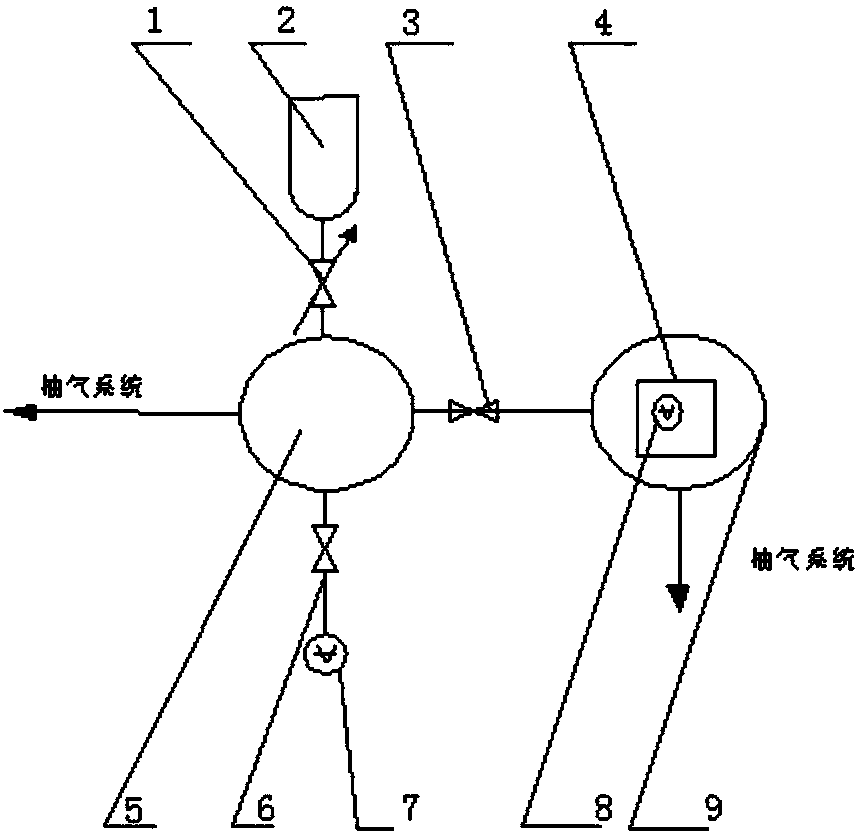

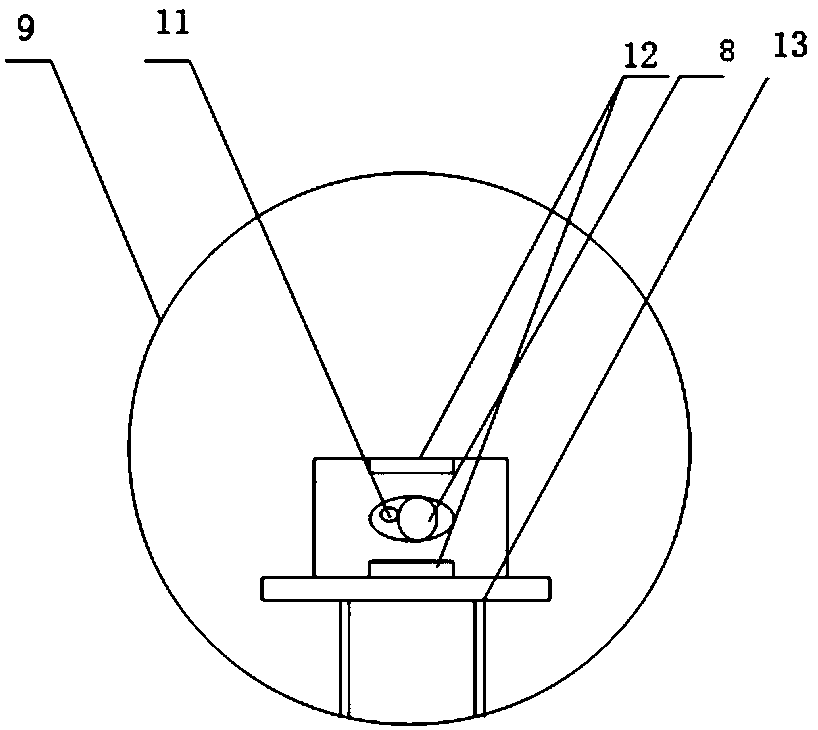

[0028] Such as Figure 1~2 As shown, a temperature control device that directly heats the calibrated vacuum gauge in the vacuum chamber, the temperature control device mainly includes a block heating unit 12, a temperature sensor 11, an electric control unit, a heating fixture and a heating fixture base 13 ;

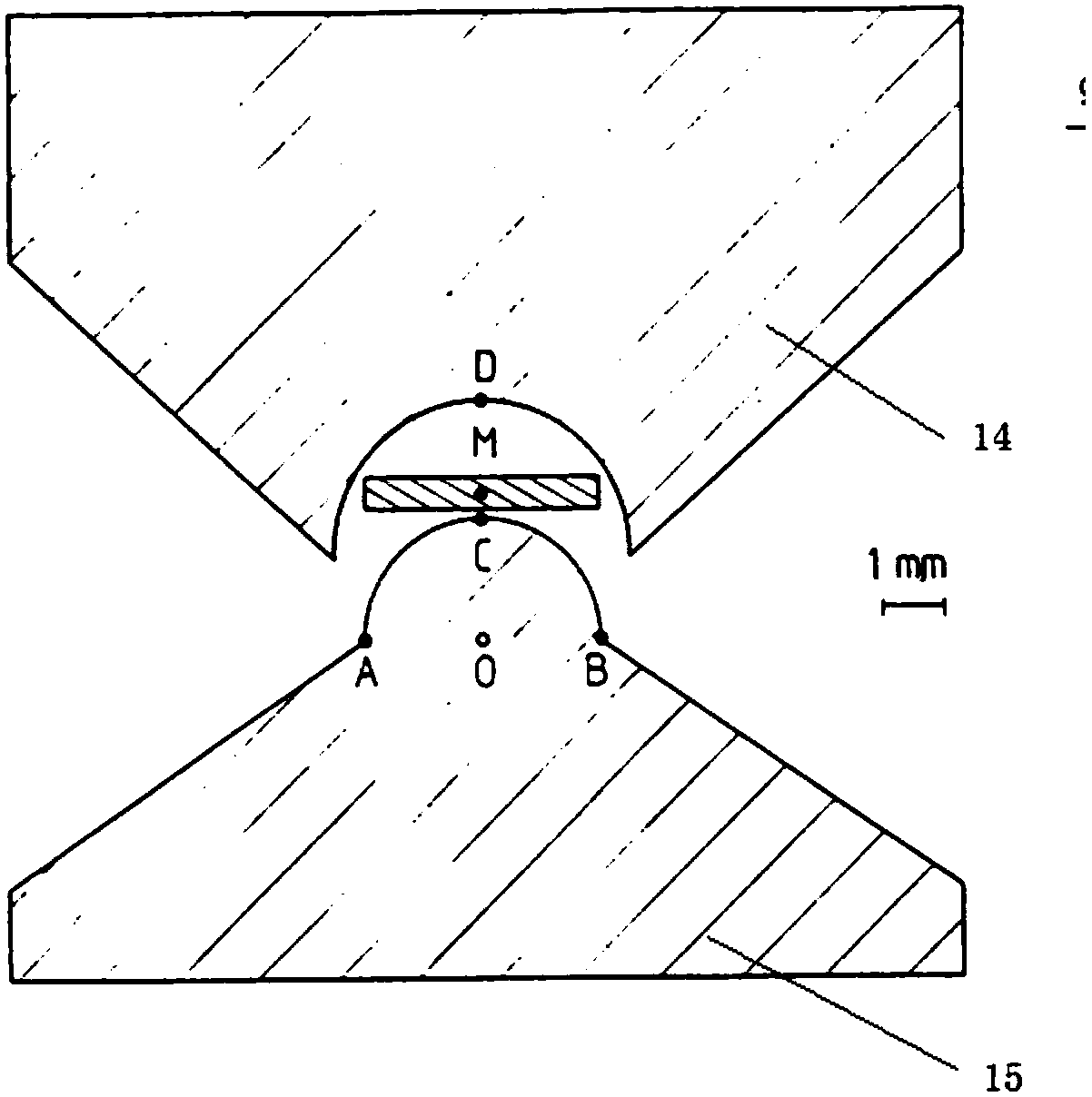

[0029] Wherein, the heating fixture is composed of a concave heating block 14 and a convex heating block 15; the concave heating block 14 and the convex heating block 15 are both shaped column structures, and a semicircle is processed on one side of the concave heating block 14 shaped groove, a semicircular protrusion is processed on one side of the convex heating block 15;

[0030] The block heating unit 12 is two pieces, which are closely connected with the concave heating block 14 and the convex heating block 15 of the heating fixture respectively; The lower concave surface of the heating block 14 is arranged opposite to the upper convex surface of the convex heatin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com