A medium frequency heating temperature control device

A temperature control device and heating technology, applied in the direction of temperature control, non-electric variable control, control/regulation system, etc., can solve the problems of large thermal resistance of thermally conductive insulating magnesium powder, large heat loss of thermal conduction, and easy oxidation and damage of electric heating wire. , to achieve the effect of less potential safety hazards, long service life, improved heating/cooling effect and heat exchange effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

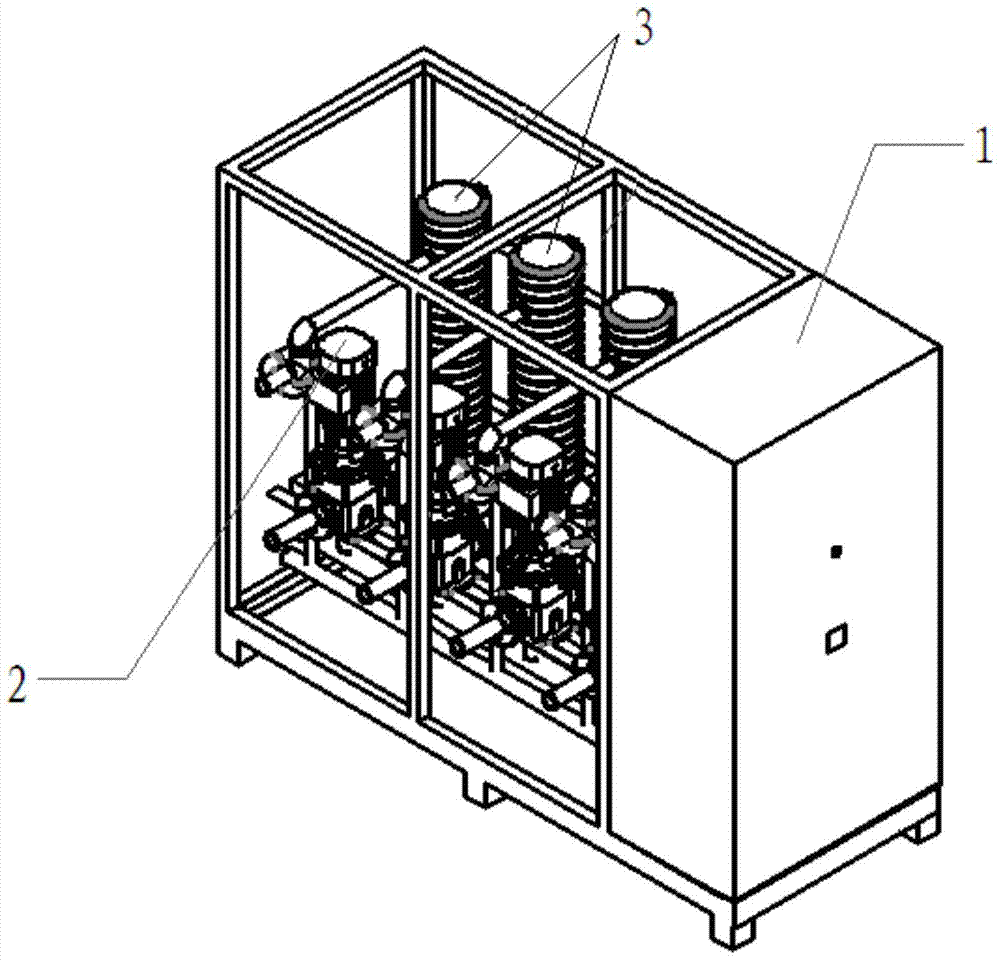

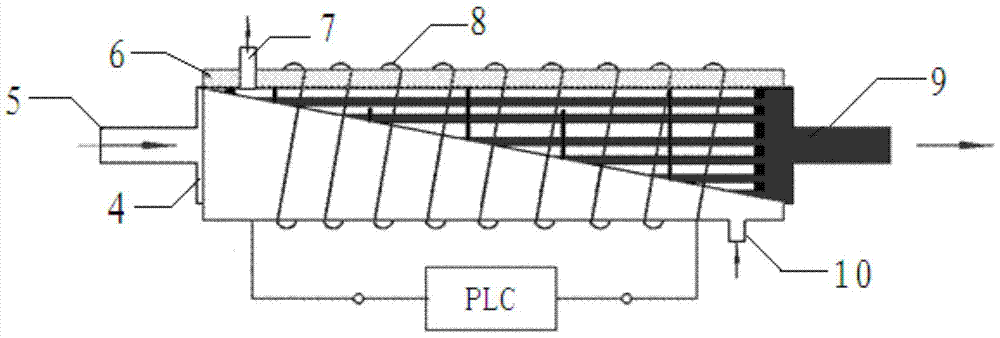

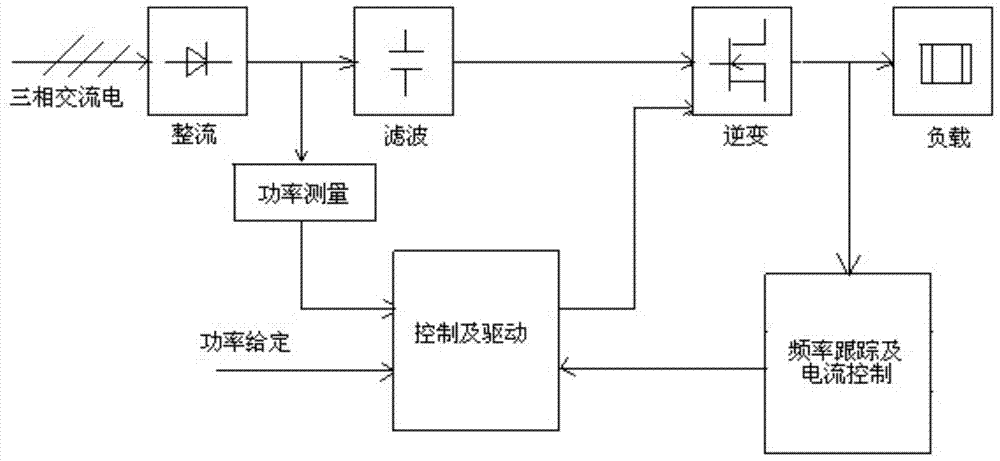

[0022] The intermediate frequency heating type temperature control device involved in this embodiment is used in conjunction with various types of temperature control equipment, and its main structure (such as figure 1 As shown) includes three parts: a control unit 1, a circulation unit 2 and a heating and cooling unit 3. The control unit 1 includes a man-machine interface connected with electrical information, a programmable logic controller (PLC), a temperature control meter, a temperature sensor and The temperature sensor transmits the detected equipment operating temperature to the PLC, and the PLC controls the heating and cooling process of the entire temperature control device through the proportional-integral-derivative (PID) mode; the circulation component 2 includes interconnected circulation pumps, Components such as control valves and control pipelines are used for high-speed circulation of the fluid medium in the equipment; heating and cooling components 3 main stru...

Embodiment 2

[0026]In this embodiment, the intermediate frequency heating type temperature control device described in Embodiment 1 is taken as an example. When it is used, it is connected with equipment and accessories that require temperature control. The temperature control temperature of the equipment that needs temperature control is preset, and the PLC realizes the automatic control of the heating, heat exchange, temperature control, and circulation functions in the circulation part 2 and the heating and cooling part 3 according to the received preset information; specifically Such as Figure 5 As shown: the fluid medium enters the heating and cooling part 3 through the fluid medium inlet 5, and after being heated by the intermediate frequency, it flows out from the fluid medium outlet 9 and is sent to the equipment requiring temperature control by the circulation pump and the control pipeline in the circulation part 2, so that The operating temperature of the equipment requiring tem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com