A kind of preparation method of in-situ self-generated aluminum-based composite material inoculant

An aluminum-based composite material, in-situ self-generated technology, applied in the field of aluminum-based alloys, can solve the problems of aggregation and precipitation, large particle size, enhanced particle dispersion distribution or unsatisfactory dispersion degree, etc., and achieve the effect of energy saving and cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] First step, ingredients:

[0032] Weigh 11g of commercially available Al-2.8%B master alloy and 3.5g of commercially available Al-20.2%Ce master alloy for batching, and the above percentages are percentages by weight;

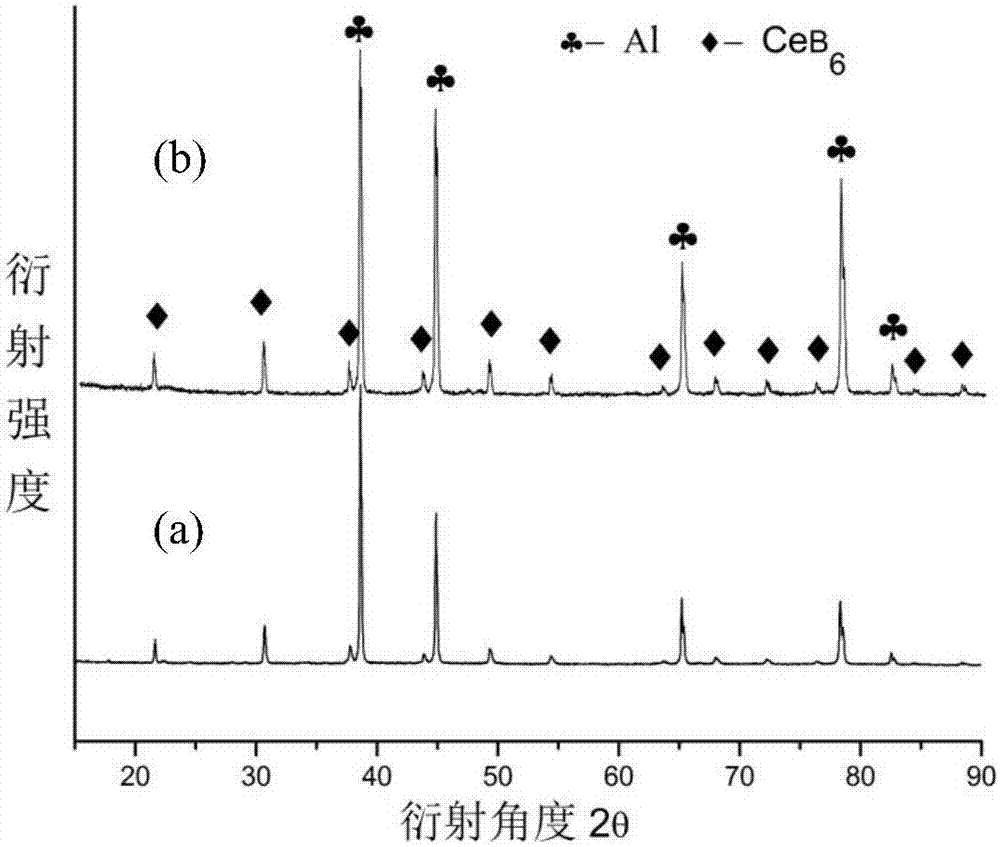

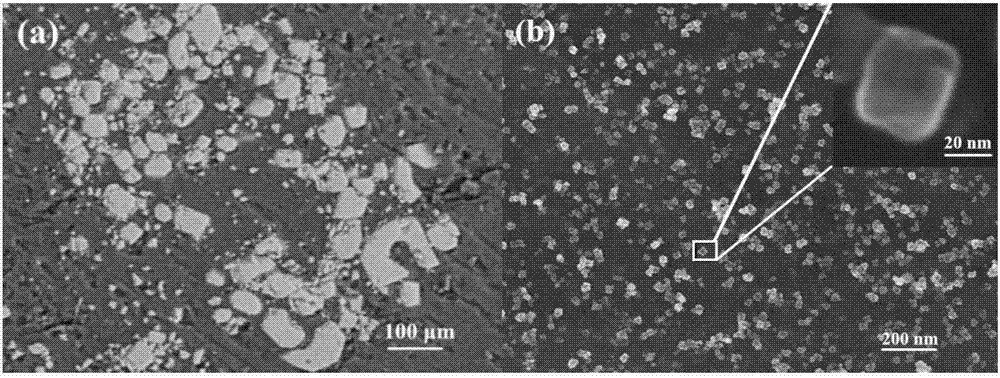

[0033] In the second step, the alloy is smelted to obtain a bulk Al-B-Ce master alloy:

[0034] Put all the ingredients weighed in the first step into the crucible of the MZG series high vacuum induction melting furnace for melting, the vacuum degree is 5×10 -3 Pa, heat the Al-2.8%B master alloy and Al-20.2%Ce master alloy to the melting temperature of 1600K, and keep it warm for 6 minutes. Ce master alloy, the bulk alloy thus prepared is cut with an electric spark cutting machine, and a sample with a length of 1 cm, a width of 1 cm, and a thickness of 0.5 cm is cut out, and the samples after cutting are respectively placed at 320#, 400#, 600# water-grinding paper for grinding, and then use alcohol to wash away impurities on the surface of the sample b...

Embodiment 2

[0039] First step, ingredients:

[0040] Weighing 22g of commercially available Al-2.8%B master alloy and 7g of commercially available Al-20.2%Ce master alloy for batching, the above percentages are percentages by weight;

[0041] In the second step, the alloy is smelted to obtain a bulk Al-B-Ce master alloy:

[0042] Put all the ingredients weighed in the first step into the crucible of the MZG series high vacuum induction melting furnace for melting, the vacuum degree is 5×10 -3 Pa, heat the Al-2.8%B master alloy and Al-20.2%Ce master alloy to the melting temperature of 1600K, and keep it warm for 6 minutes. Ce master alloy, the block alloy that will make is cut with electric spark cutting machine, and cuts out the sample that is 1cm in length, 1cm in width, and 0.5cm in thickness. Grind on #, 800#, 1200# and 2000# water abrasive paper, then perform mechanical polishing, use alcohol to wash away impurities on the surface of the sample through ultrasonic vibration, and use ...

Embodiment 3

[0046] First step, ingredients:

[0047] Weighing 44g of commercially available Al-2.8%B master alloy and 14g of commercially available Al-20.2%Ce master alloy for batching, the above percentages are percentages by weight;

[0048] In the second step, the alloy is smelted to obtain a bulk Al-B-Ce master alloy:

[0049] Put all the ingredients weighed in the first step into the crucible of the MZG series high vacuum induction melting furnace for melting, the vacuum degree is 5×10 -3 Pa, heat the Al-2.8%B master alloy and Al-20.2%Ce master alloy to the melting temperature of 1600K, and keep it warm for 6 minutes. Ce master alloy, the block alloy that will make is cut with electric spark cutting machine, and cuts out the sample that is 1cm in length, 1cm in width, and 0.5cm in thickness. Grind on #, 800#, 1200# and 2000# water abrasive paper, then perform mechanical polishing, use alcohol to wash away impurities on the surface of the sample through ultrasonic vibration, and use...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com