Production method for recovering and purifying electronic-grade hexafluoroethane from carbon tetrafluoride production industrial waste gas

A technology of carbon tetrafluoride and hexafluoroethane, which is applied in the field of recovery and purification of electronic grade hexafluoroethane, can solve the problems of ozone layer destruction, high cost, and many by-products, so as to reduce emissions, improve recovery rate, and realize resource recovery. The effect of efficient utilization and energy saving and emission reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

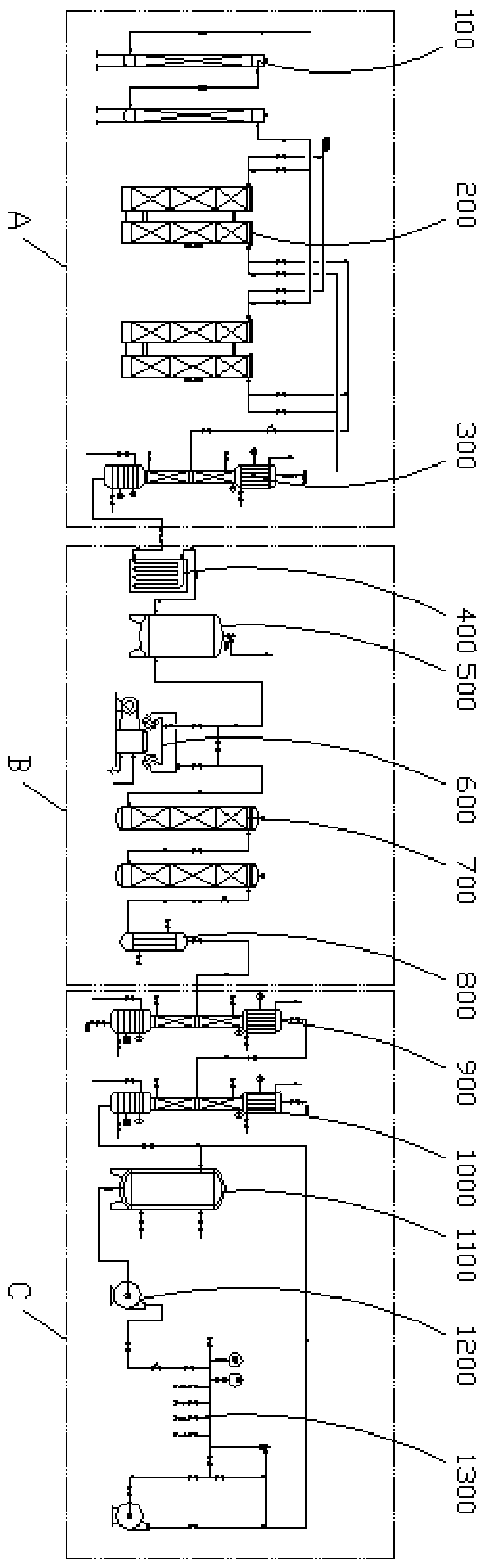

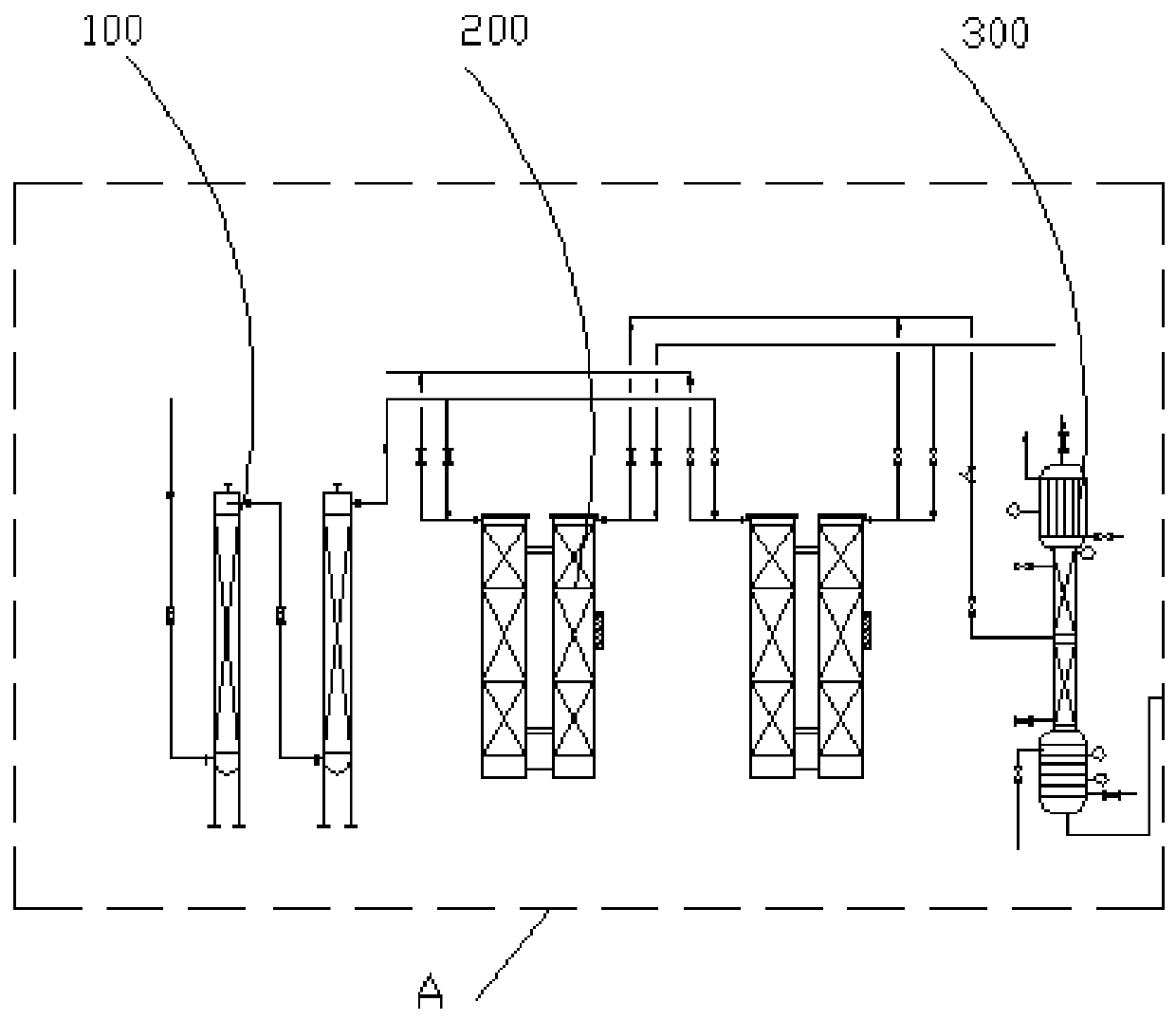

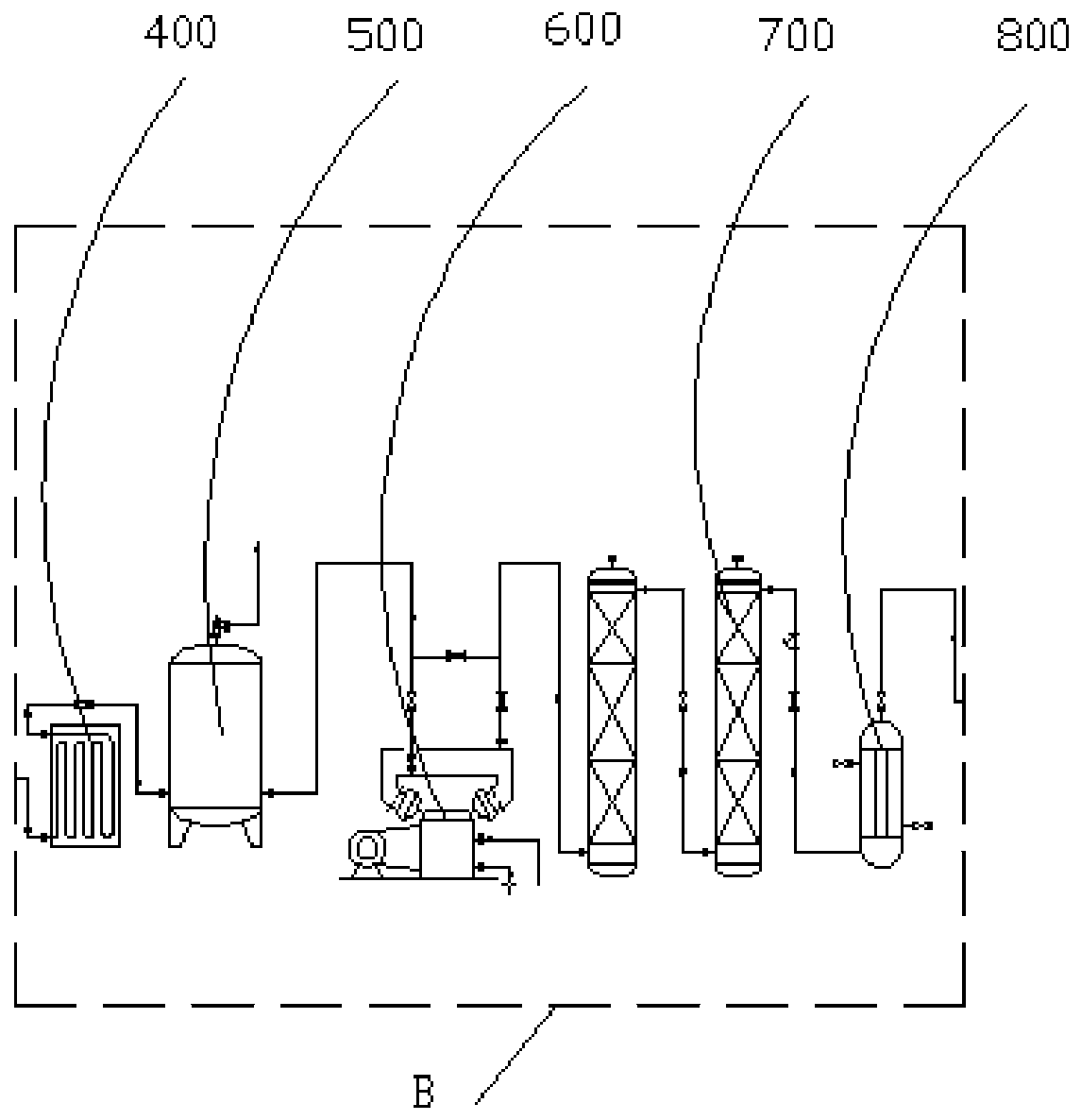

[0031] A kind of production method of recovering and purifying electronic-grade hexafluoroethane from carbon tetrafluoride production industrial waste gas of the present invention, such as Figure 1-6 shown, including the following steps:

[0032] Step 1: including a thermal decomposition and purification device 100 for recovering hexafluoroethane in carbon tetrafluoride waste gas, and controlling the flow rate of raw materials by setting a flow meter on the pipeline, and removing thermally decomposable micro oxygen through the thermal decomposition and purification device 100, Convert it into compounds that can be absorbed and removed by rectification;

[0033] Specifically, the thermal decomposition and purification device 100 cracks a small amount of oxidized substances through the electric heat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com