Production method of hexafluoroethane

A kind of technology of hexafluoroethane and chloropentafluoroethane, applied in the field of production technology of hydrofluorocarbons, can solve problems such as azeotrope

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

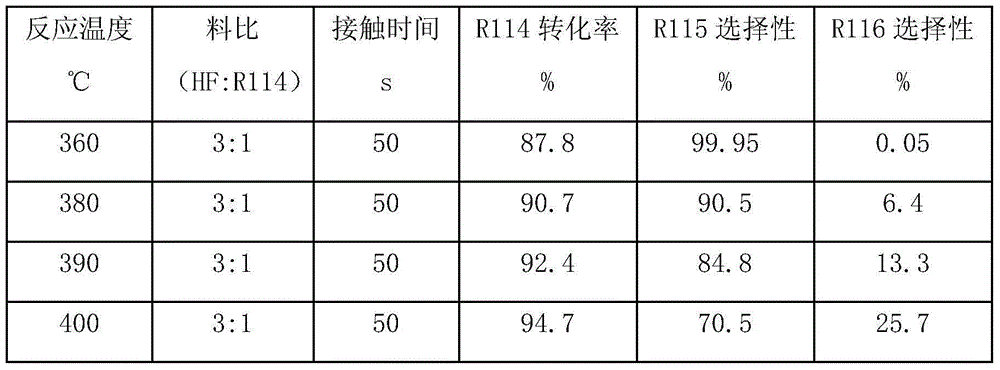

[0021] A nickel-based alloy tube with an inner diameter of 25 mm is filled with 60 ml of a chromium-based catalyst (containing magnesium and the mass ratio of magnesium to chromium is about 2%). Introduce nitrogen and hydrogen fluoride to carry out catalyst treatment for 16 hours. Then feed 20 ml / min of dichlorotetrafluoroethane and 5 ml / min of hydrogen fluoride into the reactor. The reaction conditions are: the molar ratio of hydrogen fluoride and tetrafluorodichloroethane is 3:1, the reaction temperature is 360°C, the contact time is 50s, and the reaction pressure is 0.2MPa. Table 1 shows the conversion rate of R114 and selectivity of R115 and R116 obtained at reaction temperatures of 360°C, 380°C, 390°C, and 400°C.

[0022] Table 1 Comparison of experimental data

[0023]

Embodiment 2

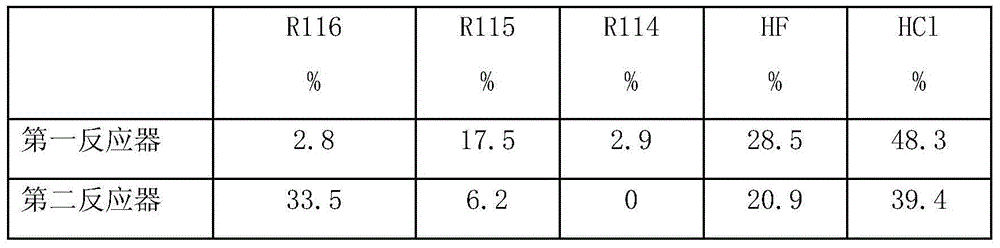

[0025] In a stainless steel tube with an inner diameter of 50 mm, the outer wall is heated by an electric heating wire, and 200 ml of a chromium-based catalyst (containing aluminum and the mass ratio of aluminum to chromium is about 2%) is filled inside. The other reactor is in a nickel-based alloy tube with an inner diameter of 25mm, the heating method is molten salt heating, and 60ml of chromium-based catalyst is filled inside. Both reactors were fed with nitrogen and hydrogen fluoride for catalyst treatment for 16 hours. Then, 30 ml / min of dichlorotetrafluoroethane and 7 ml / min of hydrogen fluoride were fed into the reactor. The first reactor is connected in series with the second reactor. The basic conditions of the reaction are: the molar ratio of hydrogen fluoride to tetrafluorodichloroethane is 4:1, the first reaction temperature is 360°C, the contact time is 50s, and the reaction pressure is 0.2MPa. The second reaction temperature is 400° C., the contact time is 80 s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com