Use of alternate refrigerants in optimized cascade process

a cascade process and refrigerant technology, applied in the direction of lighting and heating apparatus, chemistry apparatus and processes, solidification, etc., can solve the problems of flammable materials, vapor cloud explosion, and certain inherent safety risks of hydrocarbon processing techniques

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

[0052]In this Example, laminar burning velocities for various compounds were measured. The tests were performed using a constant-volume vessel in which gases were introduced using a partial pressure method, allowed to mix, and ignited. The resulting dynamic pressure trace was analyzed in order to calculate the LBV.

[0053]The measured LBV values are summarized in Table 1 below. The reactivity of a compound increases as LBV increases. This reactivity is typically a function of the strength of hydrogen bonding in the compound and not the heat of combustion or the thermal unit (e.g., BTU) value.

TABLE 1CompoundLBV (m / s)Methane~0.40Propane~0.46Ethylene~0.75Acetylene~1.55Hydrogen~3.25

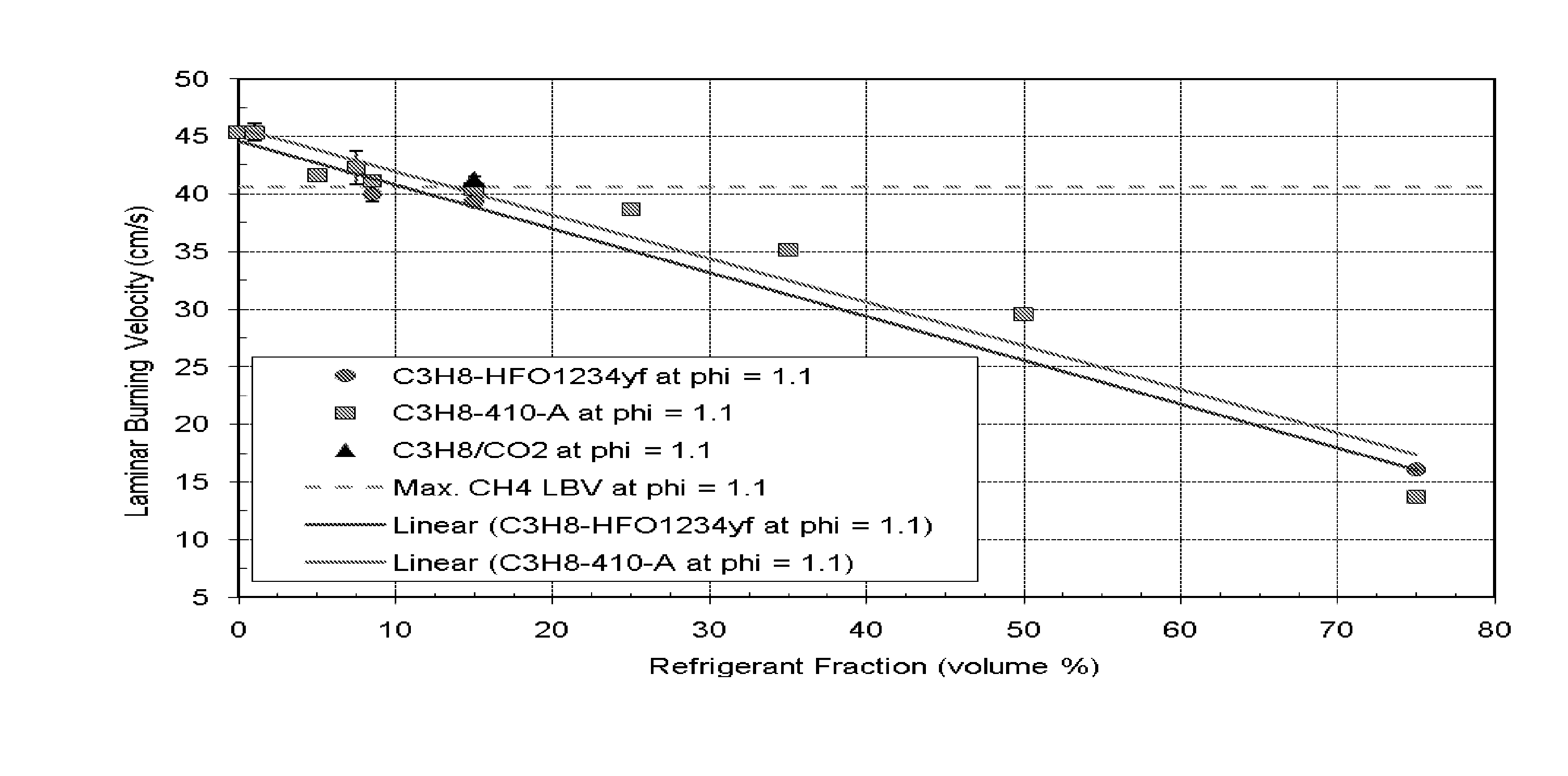

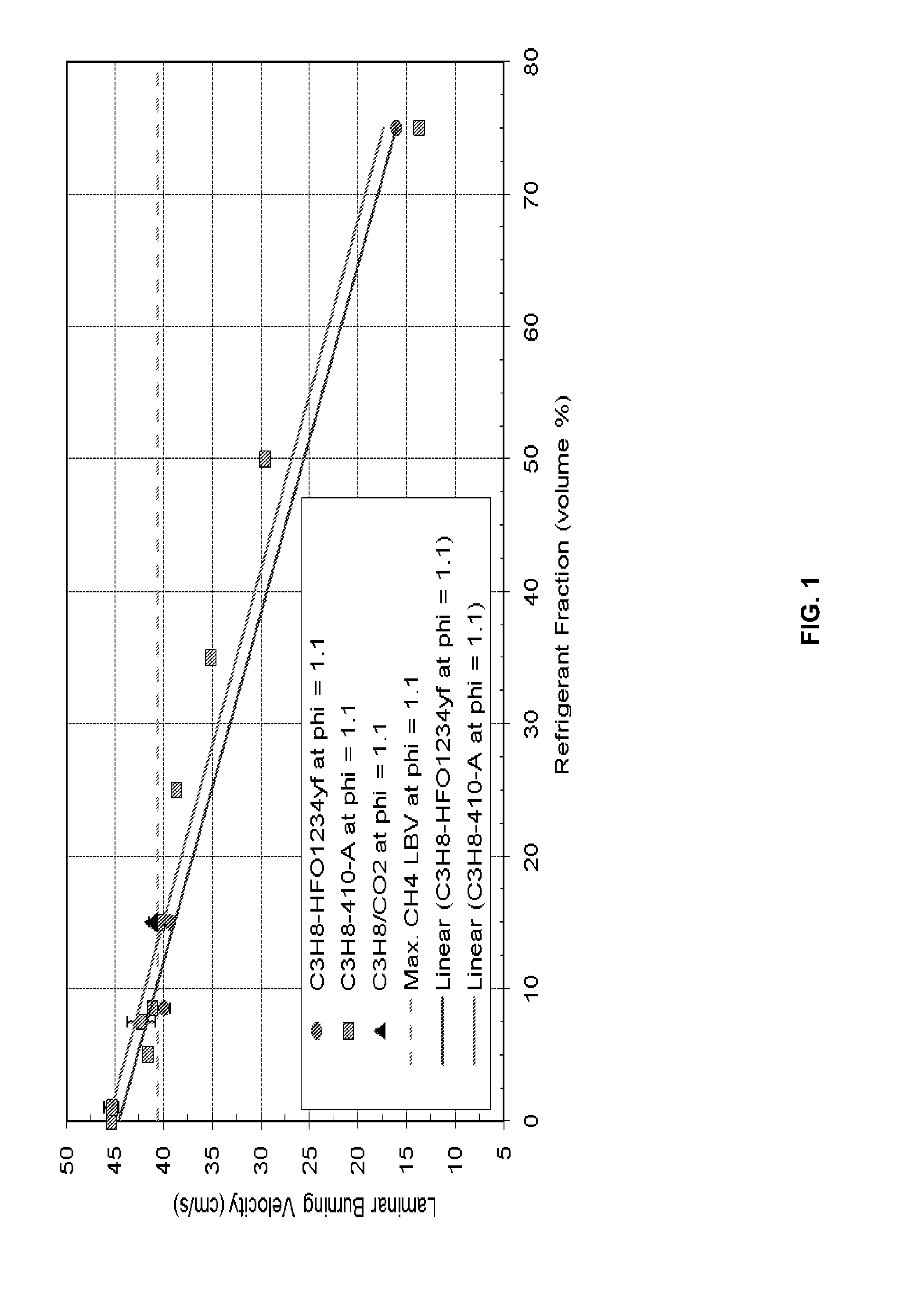

[0054]FIG. 1 illustrates the results of an experiment in which various nonflammable refrigerants and compounds such as hydrofluoro-olefin (HFO1234yf), R-410A, and CO2 were added to propane. As the nonflammable refrigerant fraction increases, the laminar burning velocity decreases.

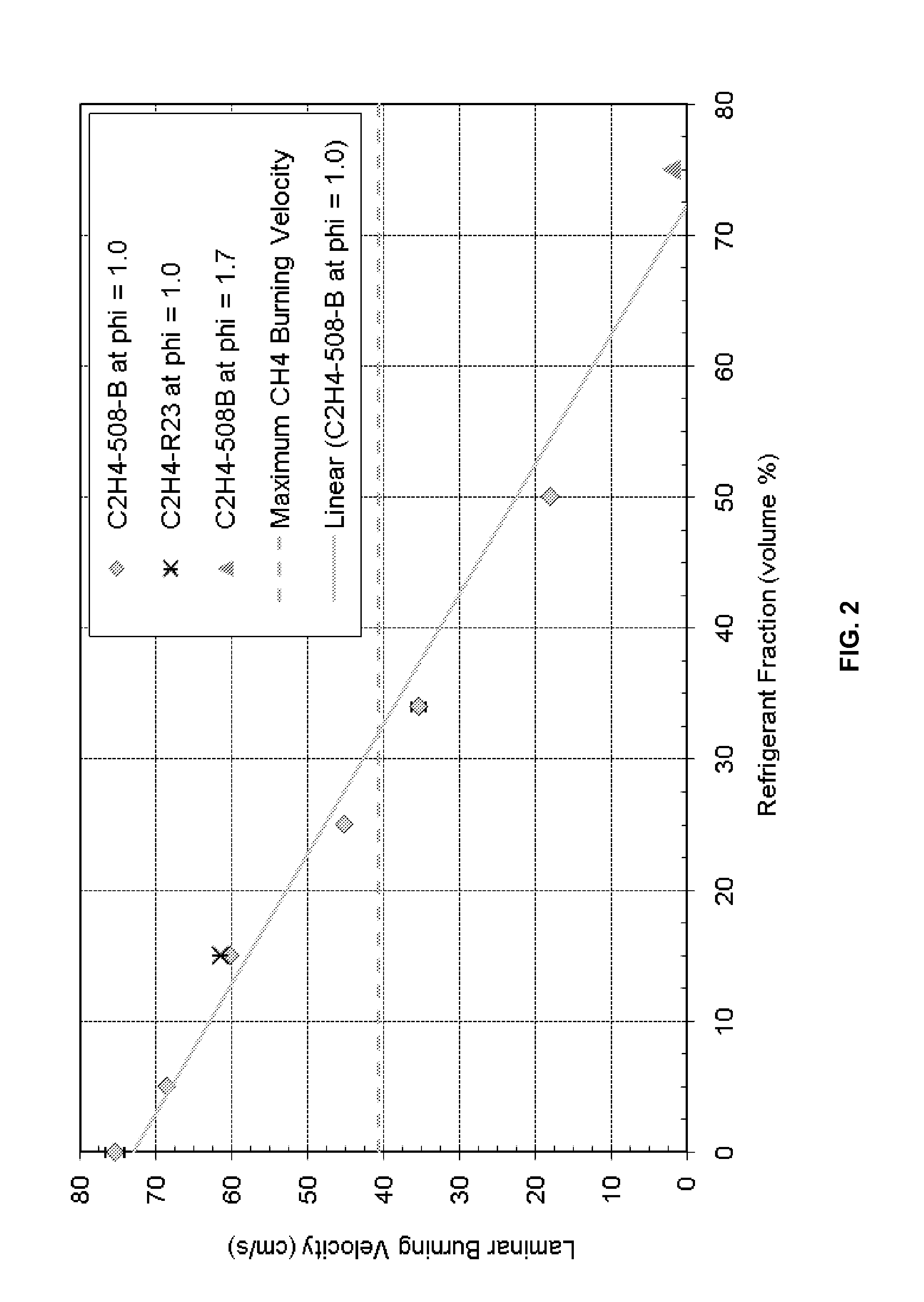

[0055]FIG. 2 illustrates the re...

example 2

[0056]Certain characteristics of an optimized cascade process improved when R-410A was used as a nonflammable refrigerant in place of propane. These characteristics were simulated using REFPROP (version 8) in the Aspen Physical Property System and verified against National Institute of Standards and Technology (NIST) tables. For example, the actual air compressor capacity (ACFM) decreased by 10-30% which allows for a smaller compressor bundle. R-410A also provides a greater vapor density (69.4 kg / m3) as compared to propane (25.6 kg / m3) which permits higher system mass flow and reduces pressure drop losses, allowing smaller diameter piping and smaller equipment to obtain the same refrigerant duty achieved by propane. Table 2 below summarizes simulated properties of R410A using Aspen HYSYS®, a modeling software available through Aspentech Technology, Inc. (Burlington, Mass.). These results suggest that R410A may be stable and behaves predictably throughout the given temperature range....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com