Hexafluoroethane purifying method

A technology of hexafluoroethane and metal catalysts, applied in the disproportionation separation/purification of halogenated hydrocarbons, organic chemistry, etc., can solve the problems of unfavorable industrialization, reduced catalytic ability of catalysts, complex reaction devices, etc., and achieve easy operation and long service life , The effect of simple removal process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] Hexafluoroethane first passes through the water washing tower, the alkali washing tower, and then through the reactor, and the reactor is equipped with loaded Fe 2 o 3 and SrTiO 3 Activated alumina catalyst, after the gas passes through the reactor, it first enters the adsorption tower, and then enters the rectification tower for rectification. Specific steps:

[0016] (1) will contain H 2 , O 2 , N 2 、CH 4 、CF 4 , CO, CO 2 , SF 6 , HCFCs, C 3 f 8 、H 2 Hexafluoroethane gas with impurities such as O and HF is passed into the water washing tower and alkali washing tower to remove HF;

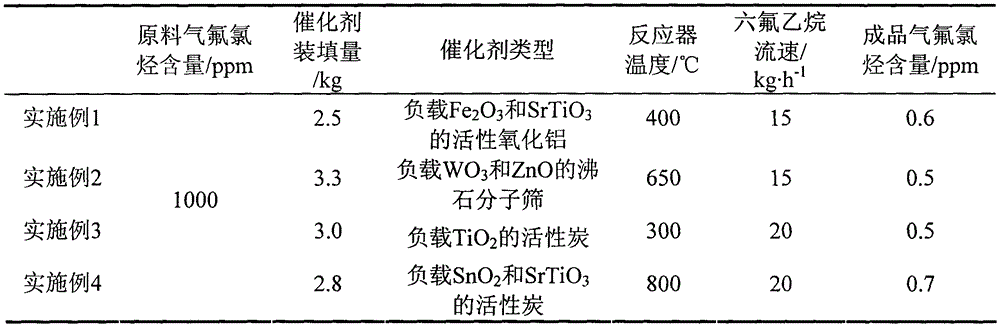

[0017] (2) The hexafluoroethane gas at the outlet of the alkali washing tower is passed into the reactor, and the reactor is equipped with a load Fe 2 o 3 and SrTiO 3 Activated alumina catalyst, the reactor temperature is controlled at 400°C, the flow rate of hexafluoroethane is controlled at 15kg / h, and the content of chlorofluorocarbons in the gas after the reactor is reduc...

Embodiment 2

[0020] The temperature of the reactor is controlled at 650°C, and the reactor is loaded with WO 3 And the zeolite molecular sieve catalyst of ZnO, hexafluoroethane flow rate is 15kg / h, other is the same as embodiment 1, and the results are shown in Table 1.

Embodiment 3

[0022] The temperature of the reactor is controlled at 300°C, and the reactor is loaded with TiO 2 active carbon catalyst, hexafluoroethane flow rate is 20kg / h, other with embodiment 1, the results are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com