Non-combustible mixing refrigerant suitable for deep refrigeration temperature of minus 80 DEG C to minus 100 DEG C

A mixed refrigerant and cryogenic technology, applied in the direction of heat exchange materials, chemical instruments and methods, etc., can solve the problems of poor oil solubility at low temperature, poor mutual solubility, environmental protection characteristics, etc., and achieve the effect of low greenhouse effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-3

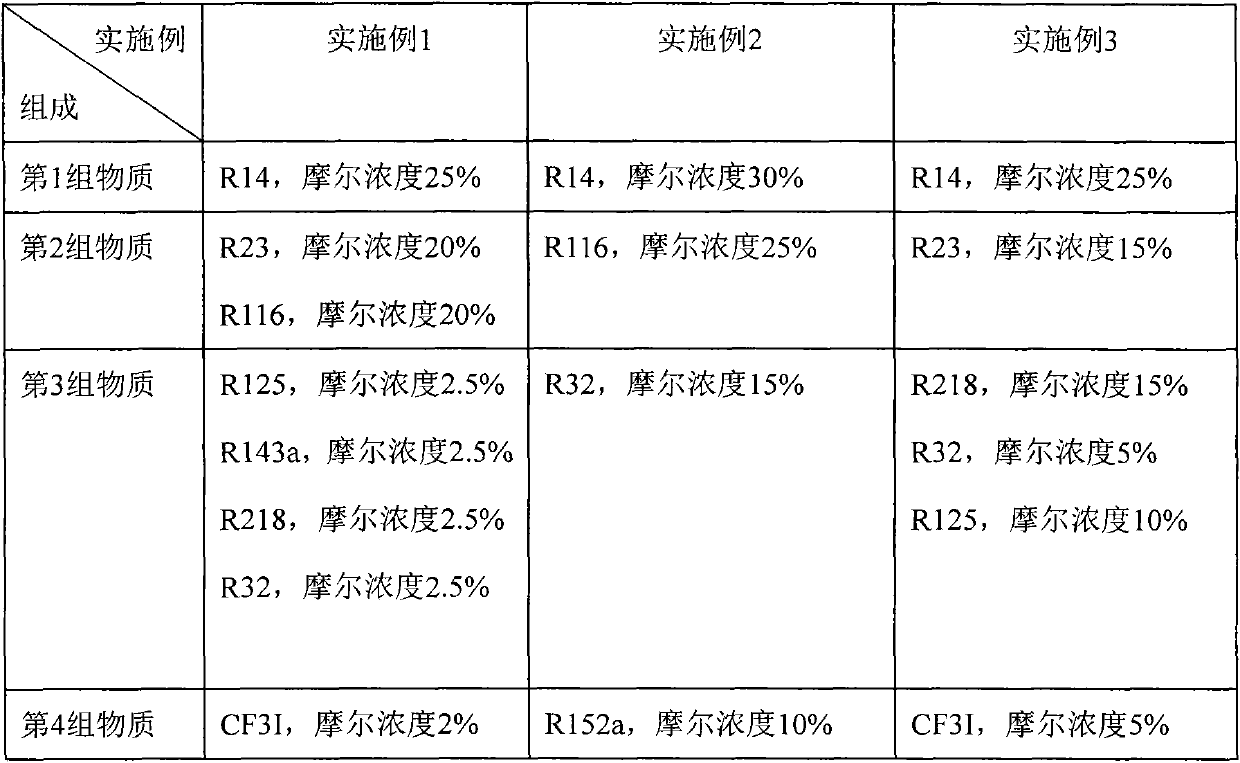

[0030] Prepare the non-flammable multi-component mixed refrigerant of the present invention that operates in the temperature range of -80°C. The minimum heat transfer temperature difference inside the heat exchanger is 1K, and the ambient temperature is 27°C. The working medium concentration and performance of the non-flammable multi-component mixed refrigerant are shown in the table below :

[0031]

[0032]

Embodiment 2

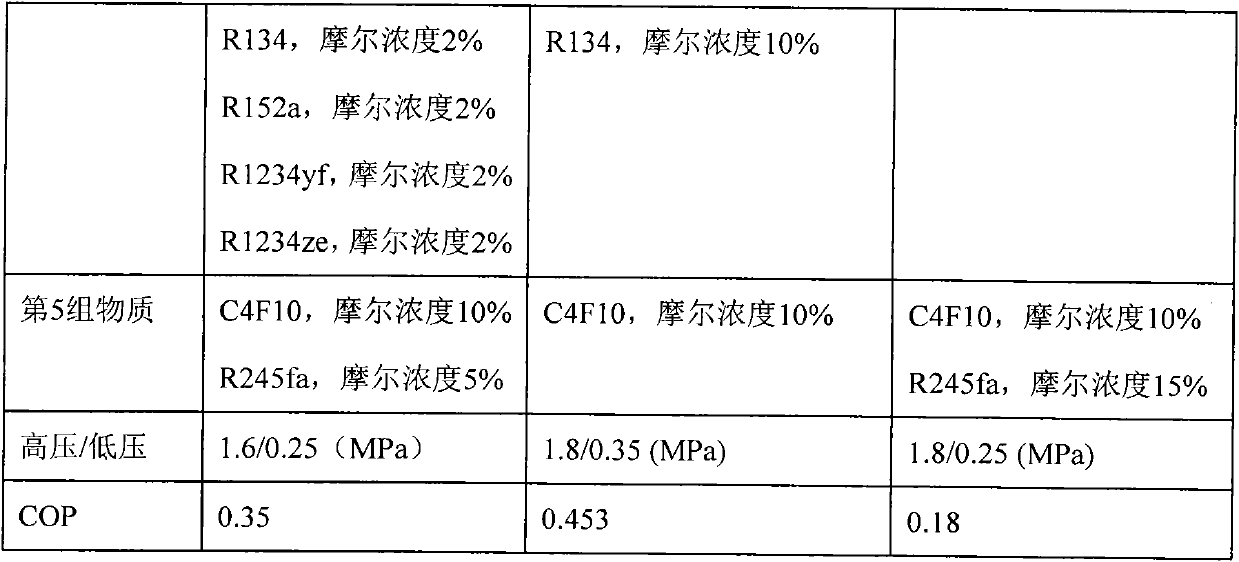

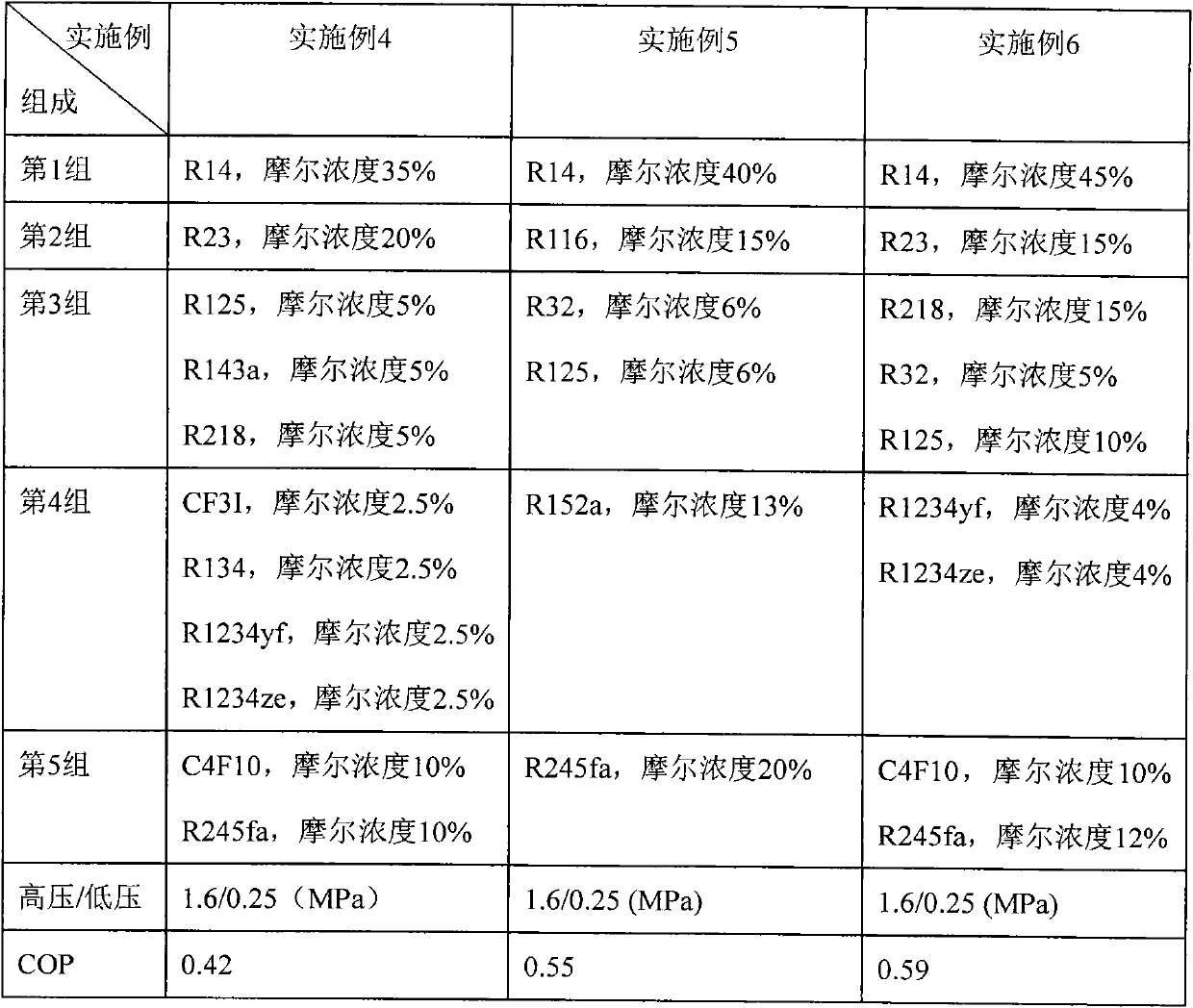

[0033] Example 2: Preparation of a non-flammable multi-component mixed refrigerant operating in the temperature range of -86°C. The minimum heat transfer temperature difference inside the heat exchanger is 1K, and the ambient temperature is 27°C. The working medium concentration and performance of the non-flammable multi-component mixed refrigerant are shown in The following table:

[0034]

Embodiment 3

[0035] Example 3: Preparation of a non-flammable multi-component mixed refrigerant operating in the temperature range of -100°C. The minimum heat transfer temperature difference inside the heat exchanger is 1K, and the ambient temperature is 27°C. The working medium concentration and performance of the non-flammable multi-component mixed refrigerant are shown in The following table:

[0036]

[0037] In the above embodiments, the regenerative refrigeration system with non-flammable mixed refrigerants can safely and efficiently realize cooling in the temperature range of -80 to -100°C. Compared with the existing cryogenic mixed refrigerants, it has no Flammability, and the overall low greenhouse effect, no ozone depletion effect, has significant advantages.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com