Hexafluoroethane production technology

A hexafluoroethane and production process technology, applied in the field of hydrofluorocarbon production process, can solve problems such as increased equipment investment and complicated process flow

Active Publication Date: 2014-05-07

SINOCHEM LANTIAN +1

View PDF6 Cites 8 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

This often complicates the process and increases equipment investment.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

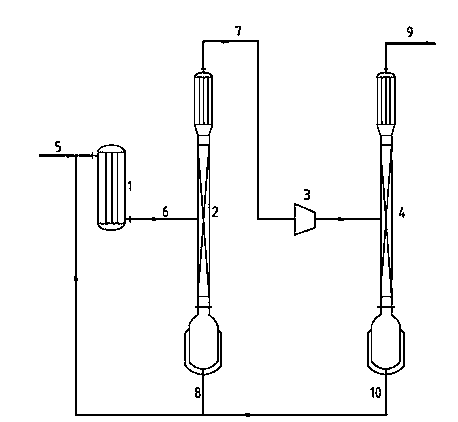

The invention discloses a hexafluoroethane production technology, and the purity of a hexafluoroethane product can reach more than 99.99% by two-stage separation and purification. The hexafluoroethane production technology simplifies a conventional technological process, saves equipment investment, makes the reaction smooth, and improves the production efficiency.

Description

technical field [0001] The invention relates to a production process of hydrofluorocarbons, in particular to a process for producing hexafluoroethane. Background technique [0002] Hexafluoroethane can be used as a cleaning or etching gas for semiconductors. For its preparation method, report has following several kinds at present: (1) Anhydrous hydrogen fluoride in the presence of a fluorination catalyst to fluorinate hydrochlorofluorocarbons such as dichlorotetrafluoroethane or chloropentafluoroethane; (2) Direct fluorination of tetrafluoroethane and / or pentafluoroethane with fluorine gas. When the method (1) is adopted, since the sources of hydrochlorofluorocarbons in each process are different, the organic impurities brought in from the raw materials are different. To obtain higher purity hexafluoroethane, the raw material must be purified. The raw material purification process includes simple distillation, rectification, and adsorption of activated carbon and mo...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C07C19/08C07C17/20

Inventor 柴华杨会娥李峰李忠陈蜀康张文庆王刚

Owner SINOCHEM LANTIAN

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com