Water-permeable concrete

A permeable concrete and cement technology, applied in the field of concrete, can solve the problems of low steel strength, reduce the flexural coefficient, and affect the compatibility of cement, etc., and achieve the effect of increasing the flexural strength, compressive strength and water permeability coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

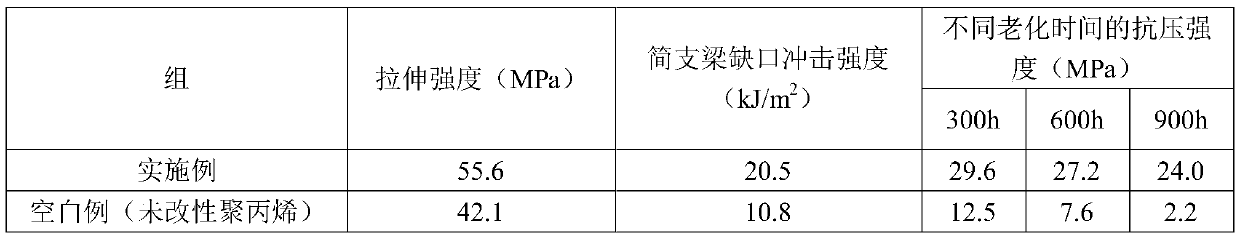

Examples

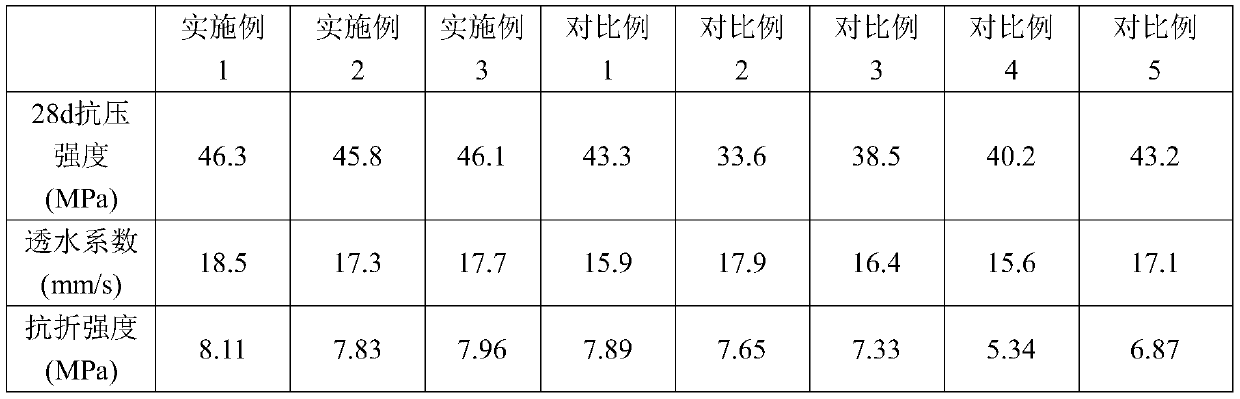

Embodiment 1

[0047] A kind of permeable concrete, by weight, comprising 108 parts of coarse aggregate, 15 parts of cement, 11 parts of water, 2.4 parts of gypsum powder, 1.5 parts of slag, 2 parts of durafiber, 12 parts of modified polypropylene particles, 0.2 parts Water reducing agent.

[0048] Preparation of permeable concrete: Mix the water reducer and water evenly to obtain a mixed solution, mix the coarse aggregate, cement, gypsum powder, slag, and Dura fiber modified polypropylene particles evenly, add the mixed solution, and stir evenly again.

Embodiment 2

[0050] A kind of permeable concrete, by weight, comprising 100 parts of coarse aggregate, 14 parts of cement, 11.2 parts of water, 2.2 parts of gypsum powder, 1.5 parts of slag, 2.5 parts of durafiber, 10 parts of modified polypropylene particles, 0.3 parts Water reducing agent.

[0051] Prepare permeable concrete according to the method of Example 1.

Embodiment 3

[0053] A kind of permeable concrete, by weight, comprising 110 parts of coarse aggregate, 13 parts of cement, 12 parts of water, 3 parts of gypsum powder, 1.5 parts of slag, 2 parts of durafiber, 11 parts of modified polypropylene particles, 0.2 parts water reducer;

[0054] Prepare permeable concrete according to the method of Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com