Biochar modified montmorillonite and preparation method thereof

A technology of montmorillonite and biochar, applied in the direction of chemical instruments and methods, restoration of water pollutants, and polluted soil, etc., can solve the problems that the performance of ordinary montmorillonite cannot fully meet the application requirements, achieve high strength, improve The effect of service life and high water permeability coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0018] The preparation method of the strengthening modifier is to fully mix and stir 40-55 parts of biochar, 15-20 parts of white carbon black, 15-20 parts of hollow glass microspheres and 15-20 parts of mica powder, and then add calcined Heating in a furnace, calcining at 400-500°C for 30-50 minutes, and then slowly cooling to room temperature.

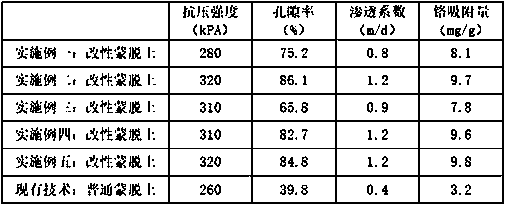

[0019] According to the above embodiments, the modified montmorillonite prepared by modifying ordinary montmorillonite has the characteristics of higher strength, larger porosity and high water permeability than ordinary montmorillonite, and can be widely used in polluted soil In the field of body restoration, the service life of montmorillonite is greatly improved, and economic benefits are enhanced. The added strengthening modifier can significantly increase the number of oxygen-containing groups of the montmorillonite, make the final product have a stable micropore structure, and enhance the adsorption capacity of pollutants. The...

Embodiment 1

[0030] Components and content: 70g of ordinary montmorillonite, 5g of modified calcium oxide, 2g of modified red mud, 2g of sodium carboxymethyl cellulose, 2g of bauxite, 3g of polyacrylate and 2g of strengthening modifier.

[0031] Wherein, the strengthening modifier consists of 40g of biochar, 15g of white carbon black, 15g of hollow glass microspheres and 15g of mica powder.

[0032] The modified calcium oxide is prepared by mixing 50g of quicklime, 1g of trehalose powder and 3g of aluminum sulfate powder and stirring evenly, heating to 45°C and keeping it for 2 hours, and then cooling to room temperature. The modified red mud is prepared by mixing 60g of red mud and 3g of phosphogypsum thoroughly, heating to 600°C and keeping it for 2 hours, and then cooling to room temperature.

[0033] Preparation:

[0034] Step 1: Mix and grind the modified calcium oxide, modified red mud and bauxite to obtain mixture A; the grinding time is 25 minutes.

[0035] Step 2: Add sodium ca...

Embodiment 2

[0038] Components and content:

[0039] Ordinary montmorillonite 80g, modified calcium oxide 8g, modified red mud 4g, sodium carboxymethyl cellulose 4g, bauxite 3g, polyacrylate 5g and strengthening modifier 3g.

[0040] The strengthening modifier consists of 50g of biochar, 18g of white carbon black, 18g of hollow glass microspheres and 18g of mica powder.

[0041] The modified calcium oxide is prepared by mixing 55g of quicklime, 1.5g of trehalose powder and 4g of aluminum sulfate powder and stirring evenly, heating to 45°C and keeping it for 2 hours, and then cooling to room temperature.

[0042] The modified red mud is prepared by mixing 65g of red mud and 4g of phosphogypsum thoroughly, heating to 600°C and keeping it for 2 hours, and then cooling to room temperature.

[0043] Preparation:

[0044] Step 1: Mix and grind the modified calcium oxide, modified red mud and bauxite to obtain mixture A; the grinding time is 25 minutes.

[0045]Step 2: Add sodium carboxymet...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com