Inorganic material adhesive and preparation method of same

A binder and inorganic technology, applied in the field of inorganic binder and its preparation, can solve the problems of pavement aging, time-consuming cleaning, easy adsorption of materials, etc., and achieve the effects of stable components, high operation rate, and avoidance of dust pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0020] The invention relates to an inorganic material binder and a preparation method thereof.

[0021] The inorganic material binder includes: a first active agent, a second active agent, a shrinkage reducing agent, an anti-white bloom agent, an inorganic pigment and a fiber;

[0022] Wherein, the first active agent is 1% to 3% of the mass of the second active agent, the shrinkage reducing agent is 0.5% to 1.5% of the mass of the second active agent, and the white bloom preventer is the second active agent 3%-6% of the mass of the second active agent, the inorganic pigment is 10%-20% of the mass of the second active agent, and the fiber is 1%-2.5% of the mass of the second active agent.

[0023] The first active agent in the inorganic material binder includes: a defoamer, a water reducer and a tackifier; the mass ratio of the defoamer to the water reducer is 0.1 to 0.3, and the water reducer The mass ratio to the tackifier is 0.8-1.2.

[0024] The second active agent in the...

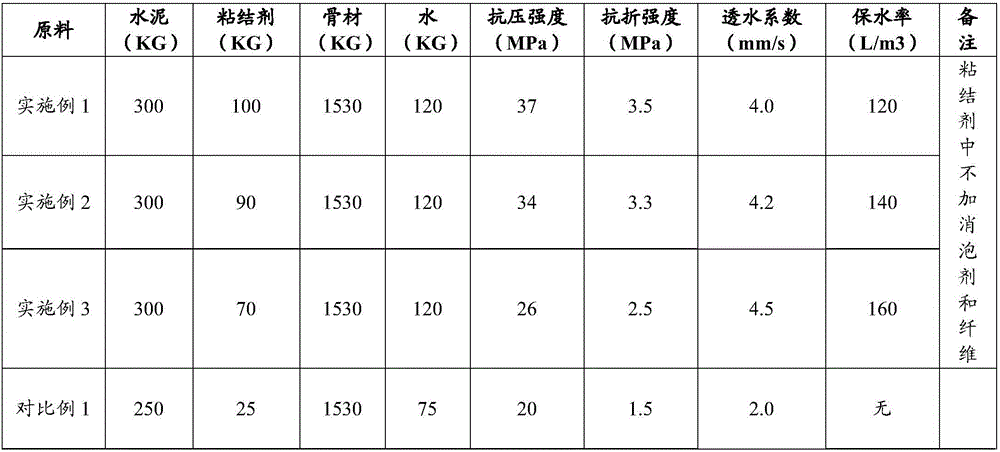

Embodiment 1~3

[0040] Put cement, aggregate, an inorganic binder according to the disclosed invention, and water into the mixer according to Table 1, and mix thoroughly so that the binder evenly covers the surface of the aggregate. The test results are shown in Table 1.

[0041] Table 1 Proportion and performance of raw materials for permeable pavement

[0042]

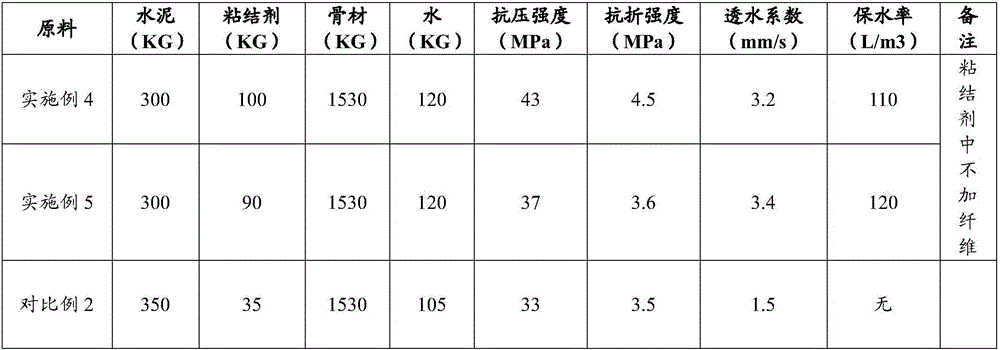

Embodiment 4~5

[0044] Put cement, aggregate, an inorganic binder according to the disclosed invention, and water into the mixer according to Table 2, and mix thoroughly so that the binder evenly covers the surface of the aggregate. The test results are shown in Table 2.

[0045] Table 2 Proportion and performance of raw materials for permeable pavement

[0046]

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com