High-property water permeation concrete cementing agent and application thereof

A technology of permeable concrete and cement, which is applied in the field of permeable concrete additives, can solve problems such as poor alkali resistance, high price, and inconspicuous reinforcement effect, and achieve the goal of improving compression resistance, best reinforcement effect and durability, and prolonging construction operation time Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

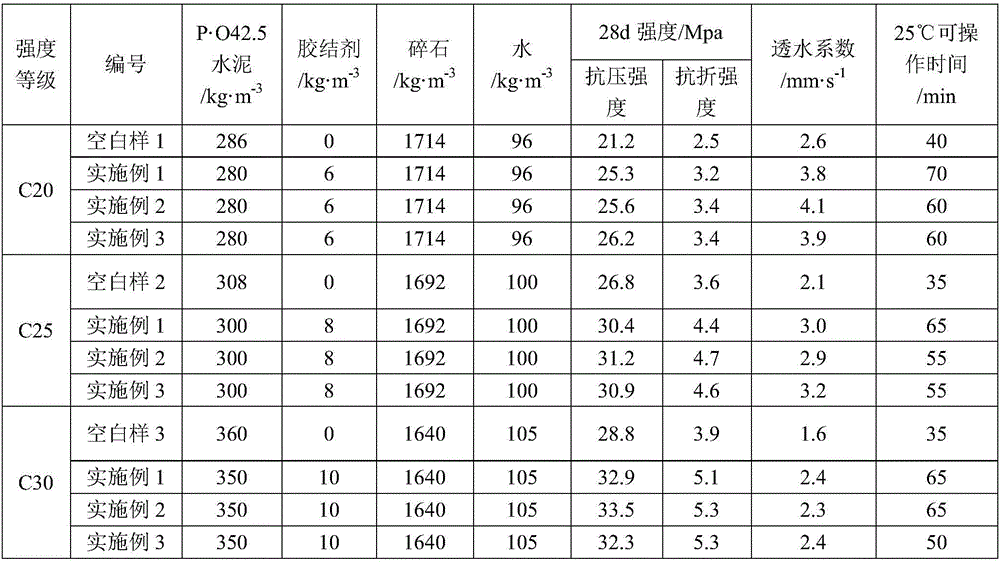

Examples

Embodiment 1

[0022] A high-performance permeable concrete binder, the raw materials of which are calculated by mass percentage: 68% of active silica powder, 18% of interface modifier, 10% of water reducer, 2% of coagulation regulator, and 2% of thickener.

[0023] In this example, SiO in active silica powder 2 The content is 92%, the 28d activity index is 105%, and the specific surface area is 20000m 2 / kg; the interfacial modifier consists of 50wt% powdered vinyl acetate and ethylene copolymer (minimum film-forming temperature 2°C) and 50wt% powdery vinyl acetate-ethylene-vinyl tert-carbonate copolymer (minimum film-forming temperature 2°C) ℃) compounded; the water reducer is an early-strength powder polycarboxylate high-efficiency water reducer with a water reducing rate of 28%; the coagulation regulator is 70wt% powdered sodium pyrophosphate (industrial grade) and 30wt% sodium phosphate (industrial grade) composite; the thickener is carboxymethyl cellulose (industrial grade).

Embodiment 2

[0025] A high-performance permeable concrete binder, the raw materials of which are calculated by mass percentage: 68% of active silica powder, 22% of interface modifier, 7% of water reducer, 3% of coagulation regulator, and 0% of thickener.

[0026] In this example, SiO in active silica powder 2 The content is 94wt%, the 28d activity index is 102%, and the specific surface area is 18000m 2 / kg; the interfacial modifier is compounded by 60wt% powdery acrylate-styrene copolymer (minimum film-forming temperature 5°C) and 40wt% powdery acrylate copolymer (minimum film-forming temperature 5°C); The agent is an early-strength powder polycarboxylate high-efficiency superplasticizer with a water reducing rate of 30%; the coagulation regulator is a compound of 20wt% sodium lignosulfonate and 80wt% sodium gluconate.

Embodiment 3

[0028] A high-performance permeable concrete binder, whose raw materials are calculated by mass percentage: 72% of active silica powder, 18% of interface modifier, 7% of water reducer, 2% of coagulation regulator, and 1% of thickener.

[0029] In this example, SiO in active silica powder 2 The content is 93wt%, the 28d activity index is 105%, and the specific surface area is 20000m 2 / kg; Interface modifier is 70wt% powdery styrene-butadiene copolymer (2 ℃ of minimum film-forming temperature) and 30wt% powdery vinyl acetate-ethylene copolymer (2 ℃ of minimum film-forming temperature); The water agent is a retarder powdery aliphatic high-efficiency water reducer, and the water reducing rate is 24%; the coagulation regulator is sodium gluconate (industrial grade); grade) and 50 wt% hydroxyethyl cellulose.

[0030]The preparation method of a kind of high-performance permeable concrete cement agent taking embodiment 1 as example, put 68kg active silicon dioxide powder into YLT-1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| activation index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com