Permeable concrete cementitious composition and preparation method thereof

A technology for permeable concrete and composition, applied in the field of permeable concrete cementitious composition and preparation thereof, can solve the problems of insignificant reinforcement effect, poor alkali resistance, high price, prolong construction operation time, improve compressive strength and high cost performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0035] Another aspect of the present invention also provides a preparation method of the permeable concrete cementitious composition, comprising the steps of:

[0036] (1) Add water into the mixing tank, start the mixer, and the rotating speed is 300-500r / min;

[0037] (2) Add anhydrous calcium chloride and sodium chloride into the stirring tank, and stir until completely dissolved for 20-40 minutes;

[0038] (3) Add polyferric sulfate into the stirring tank and stir for 8-15 minutes.

[0039] The addition of water described in step (1) is 30-70 parts.

[0040] Calcium Chloride Anhydrous

[0041] In the present application, the anhydrous calcium chloride is a salt formed by chloride ions and calcium ions, which has strong hygroscopicity and can be used in the fields of chemical reagents, pharmaceutical raw materials, food additives, feed additives, and raw materials for manufacturing calcium metal. .

[0042] In the present application, as a preferred technical scheme, th...

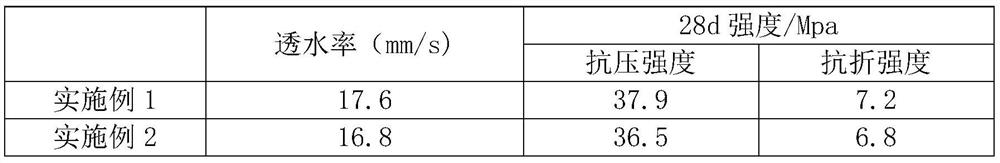

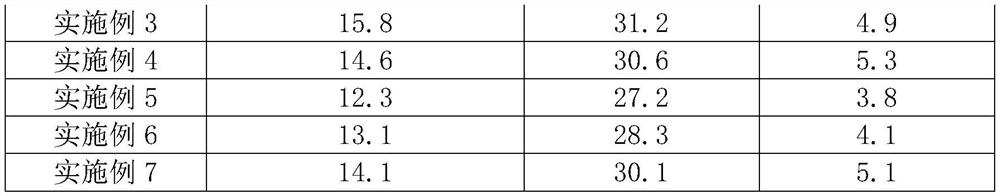

Embodiment 1

[0058] Example 1 provides a permeable concrete bonding composition, which includes the following raw materials in parts by weight: 45 parts of anhydrous calcium chloride, 4 parts of polyferric sulfate, and 1.5 parts of sodium chloride.

[0059] In the anhydrous calcium chloride, CaCl 2 Content ≥ 94wt%; Mg content is 0.3-0.5wt%, as MgCl 2 Meter; free alkali content is 0.1-0.3wt%, as Ca(OH) 2 The polyferric sulfate is an aqueous solution of polyferric sulfate; the content of polyferric sulfate in the aqueous solution of polyferric sulfate is 10wt%; the basicity of the aqueous solution of polyferric sulfate is 8-12%.

[0060] In this example, the CAS number of anhydrous calcium chloride is 10043-52-4, purchased from Zhejiang Dacheng Calcium Co., Ltd.; polyferric sulfate was purchased from Henan Haiyun Environmental Protection Technology Co., Ltd.; the CAS number of sodium chloride is 7647- 14-5, purchased from Lianyungang Guansu Industrial Co., Ltd.

[0061] Another aspect of ...

Embodiment 2

[0067] Example 2 provides a permeable concrete bonding composition, which includes the following raw materials in parts by weight: 30 parts of anhydrous calcium chloride, 1 part of polyferric sulfate, and 1 part of sodium chloride.

[0068] In the anhydrous calcium chloride, CaCl 2 Content ≥ 94wt%; Mg content is 0.3-0.5wt%, as MgCl 2 Meter; free alkali content is 0.1-0.3wt%, as Ca(OH) 2 The polyferric sulfate is an aqueous solution of polyferric sulfate; the content of polyferric sulfate in the aqueous solution of polyferric sulfate is 10wt%; the basicity of the aqueous solution of polyferric sulfate is 8-12%.

[0069] In this example, the CAS number of anhydrous calcium chloride is 10043-52-4, purchased from Zhejiang Dacheng Calcium Co., Ltd.; polyferric sulfate was purchased from Henan Haiyun Environmental Protection Technology Co., Ltd.; the CAS number of sodium chloride is 7647- 14-5, purchased from Lianyungang Guansu Industrial Co., Ltd.

[0070] Another aspect of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com