Permeable ceramic brick manufactured from rare earth tailings and manufacturing method thereof

A technology of rare earth tailings and manufacturing methods, which is applied in the field of building ceramic materials, can solve problems such as environmental pollution safety hazards, ecological environment impact, and large floor area, so as to improve water permeability coefficient, realize recycling, and reduce energy consumption and cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

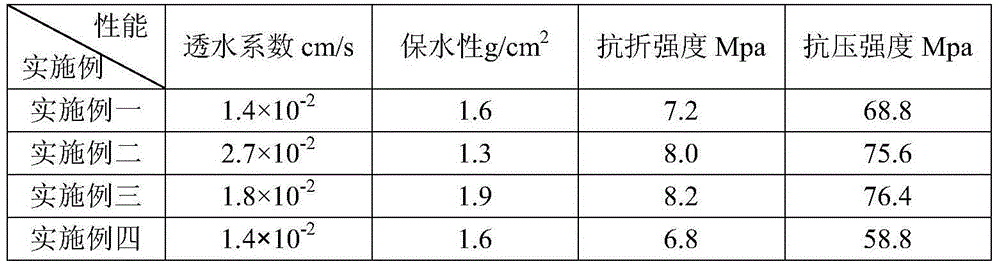

Examples

Embodiment 1

[0024] 1. In this embodiment, a ceramic permeable brick prepared with rare earth tailings, its raw material composition is:

[0025] Rare earth coarse tailings 70wt%, rare earth fine tailings 10wt%, clay 4wt%, medium temperature sand 3wt%, black talc 4.5wt%, lime 8.5wt%.

[0026] Among them, the particle gradation of rare earth coarse tailings is: 21wt% above 10 mesh sieve, 57wt% 10-30 mesh sieve, 16wt% 30-100 mesh sieve, 6wt% 100-350 mesh sieve; 2 O+Na 2 O 8.5 wt%.

[0027] 2. The manufacturing method of the above-mentioned ceramic permeable brick prepared with rare earth tailings in this embodiment, the steps are as follows:

[0028] (1) Mix and finely grind the rare earth fine tailings, clay, medium temperature sand, black talc, and lime until they all pass through a million-hole sieve to obtain the packaged material; then add the rare earth coarse tailings to the packaged material and mix in a mixer for 30 minutes to well mixed;

[0029] (2) Add water and continue to s...

Embodiment 2

[0032] 1. In this embodiment, a ceramic permeable brick prepared with rare earth tailings, its raw material composition is:

[0033] Rare earth coarse tailings 75wt%, rare earth fine tailings 6wt%, clay 3wt%, medium temperature sand 2wt%, low temperature sand 2wt%, black talc 5wt%, lime 7wt%.

[0034] Among them, the particle gradation of rare earth coarse tailings is: 23wt% above 10 mesh sieve, 50wt% by 10-30 mesh sieve, 20wt% by 30-100 mesh sieve, 7wt% by 100-350 mesh sieve; 2 O+Na 2 O 6.4 wt%.

[0035] 2. The manufacturing method of the above-mentioned ceramic permeable brick prepared with rare earth tailings in this embodiment, the steps are as follows:

[0036] (1) Mix and finely grind rare earth fine tailings, clay, medium-temperature sand, low-temperature sand, black talc, and lime until they all pass through a million-hole sieve to obtain wrapped materials; then add rare earth coarse tailings to the wrapped materials in the mixer Mix for 50 minutes until evenly mixe...

Embodiment 3

[0040] 1. In this embodiment, a ceramic permeable brick prepared with rare earth tailings, its raw material composition is:

[0041] Rare earth coarse tailings 80wt%, rare earth fine tailings 5wt%, clay 3wt%, medium temperature sand 2wt%, low temperature sand 3wt%, lime 7wt%.

[0042] Among them, the particle gradation of rare earth coarse tailings is: 16wt% above 10 mesh sieve, 56wt% on 10-30 mesh sieve, 19wt% on 30-100 mesh sieve, 9wt% on 100-350 mesh sieve; 2 O+Na 2 O 7.2 wt%.

[0043] 2. The manufacturing method of the above-mentioned ceramic permeable brick prepared with rare earth tailings in this embodiment, the steps are as follows:

[0044] (1) Mix and finely grind rare earth fine tailings, clay, medium-temperature sand, low-temperature sand, and lime until they all pass through a million-hole sieve to obtain wrapped materials; then add rare earth coarse tailings to the wrapped materials and mix in a mixer for 60 minutes to well mixed;

[0045] (2) Add water and c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com