Recovered construction waste regenerative water permeable brick and preparation method thereof

A technology of construction waste and permeable bricks, which is applied in the direction of manufacturing tools, auxiliary molding equipment, ceramic molding machines, etc., can solve the problems of low resource utilization, reduce pressure, and reduce the exploitation of natural resources, so as to reduce the pressure of urban drainage and flood control , reduce pressure, and solve the effect of urban heat island effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

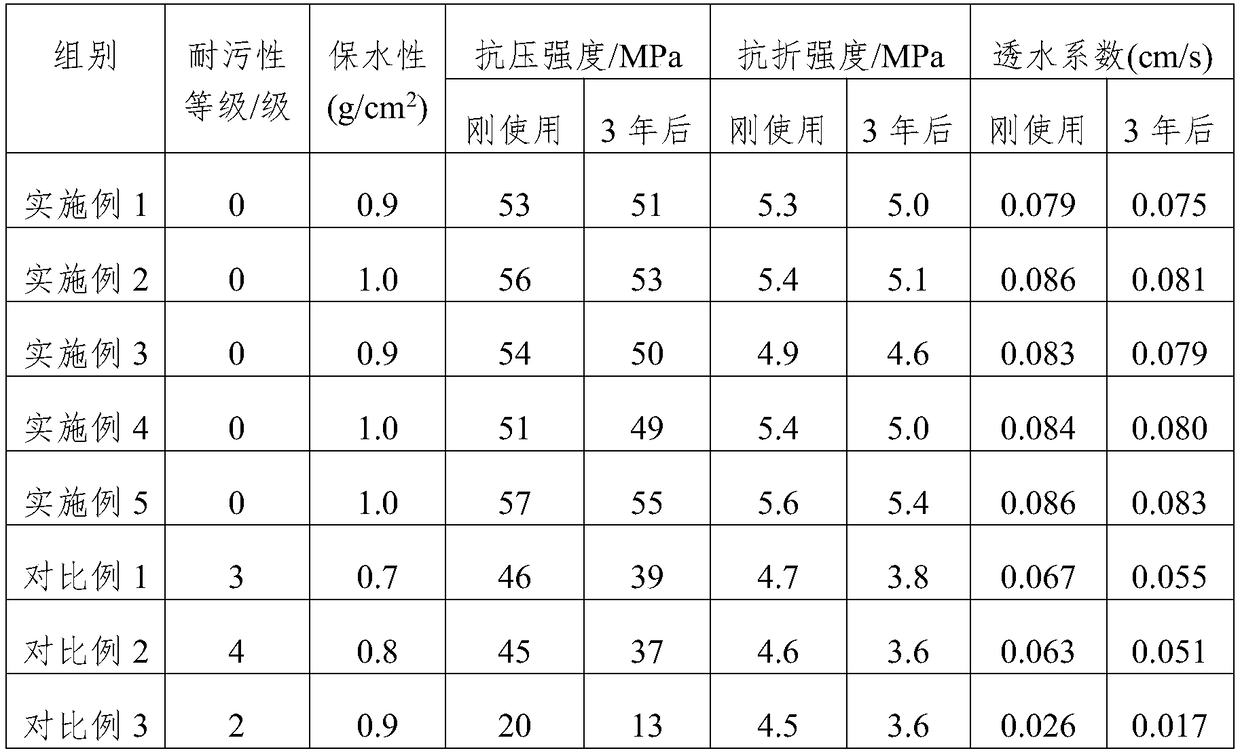

Examples

Embodiment 1

[0031] A regenerated permeable brick for recycling construction waste, which is made from the following raw materials by weight: 1800 parts of construction waste, 850 parts of municipal sludge, 300 parts of cement, 400 parts of biogas residue, 350 parts of industrial waste residue, and 350 parts of solid waste incineration residue , 150 parts of water, and the industrial waste residue is fly ash.

[0032]Further, the municipal sludge is a viscous solid sediment produced in the process of sewage treatment; the solid waste incineration residue is a solid residue produced after the incineration of domestic solid waste.

[0033] A preparation method for reclaiming construction waste regenerated permeable bricks as described above, comprising the following steps:

[0034] (1) Pretreatment: Remove impurities such as plastic bags and trees from construction waste, and then send half of the construction waste into a pulverizer to be pulverized into medium aggregates with a particle si...

Embodiment 2

[0038] A regenerated permeable brick for recycling construction waste, which is made from the following raw materials by weight: 1900 parts of construction waste, 950 parts of municipal sludge, 350 parts of cement, 500 parts of biogas residue, 450 parts of industrial waste residue, and 450 parts of solid waste incineration residue , 200 parts of water, and the industrial waste residue is slag.

[0039] Further, the municipal sludge is a viscous solid sediment produced in the process of sewage treatment; the solid waste incineration residue is a solid residue produced after the incineration of domestic solid waste.

[0040] The preparation method is the same as that of Example 1.

Embodiment 3

[0042] A regenerated permeable brick for recycling construction waste, which is made of the following raw materials by weight: 1820 parts of construction waste, 860 parts of municipal sludge, 310 parts of cement, 420 parts of biogas residue, 360 parts of industrial waste residue, and 370 parts of solid waste incineration residue , 160 parts of water, and the industrial waste residue is cinder.

[0043] Further, the municipal sludge is a viscous solid sediment produced in the process of sewage treatment; the solid waste incineration residue is a solid residue produced after the incineration of domestic solid waste.

[0044] The preparation method is the same as that of Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com